Rolling bearing component

A technology for rolling bearings and components, applied in the field of thin-walled rolling bearing components, can solve problems such as expensiveness, accuracy, cracks, etc. that affect the overall size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

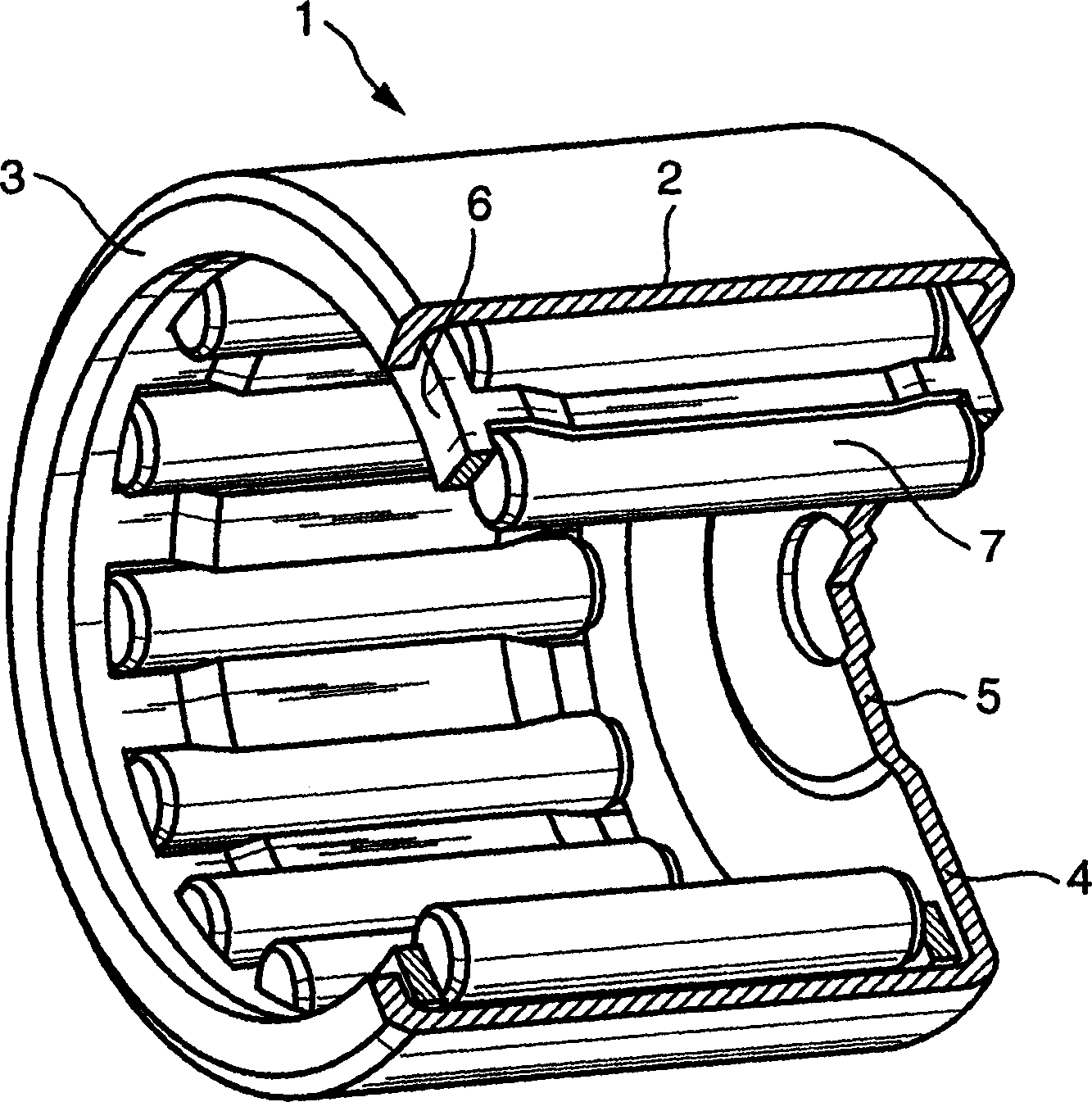

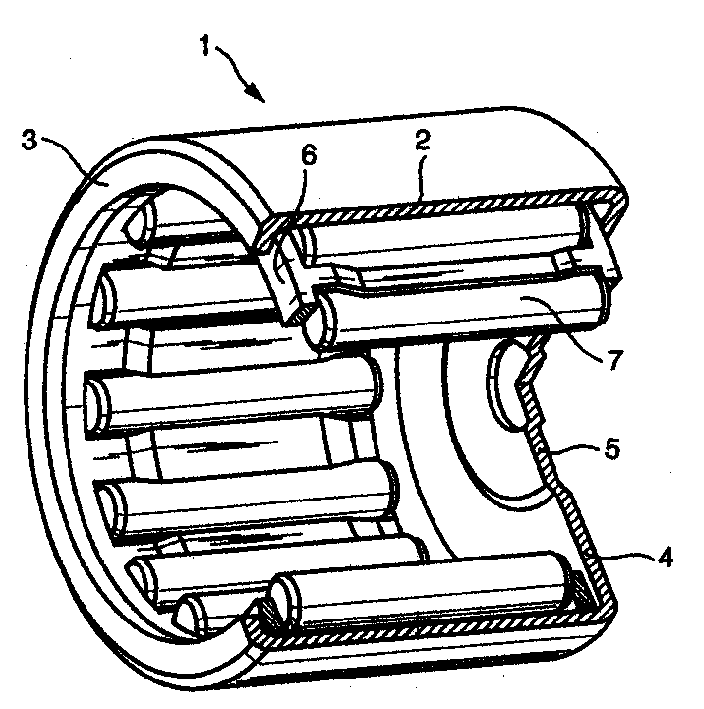

[0046] The needle roller bushing shown in the drawing and marked with 1 has a radial section 2 of circular ring contour, one end of which is bent into a radially inward rim 3 and the other end is closed with a base plate 4 . Needle rollers 7 in a cage 6 are placed rolling between the base plate 4 provided with the bulge 5 and the rim 3 . Such a needle roller bushing 1 surrounds the bearing point of the shaft end.

[0047]The needle roller sleeve 1 is formed by a high-quality steel cold-rolled strip with a thickness of 1.2mm and the following chemical composition through multiple processing steps: 0.40%C, 0.10%Si, 0.5%Mn, 0.10%Mo, 0.3%Cr , 0.01% P, 0.005% S, 0.1% Cu, 0.1% Ni, 0.005% Sn, 0.002% Sb, wherein the sum of Cu, Ni, Mn and Cr is 1.02%. In addition, fine-grain stabilizing elements such as aluminium, titanium and niobium can be present in a total composition of 0.06%. The cage 6 is made of carburized steel marked St3, and the needle roller 7 is made of hardened steel ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com