Steel with good cutting and cutting breaking performance for physical construction

A technology of mechanical structure and machinability, applied in the field of steel for mechanical structure, can solve the problems of machinability dispersion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

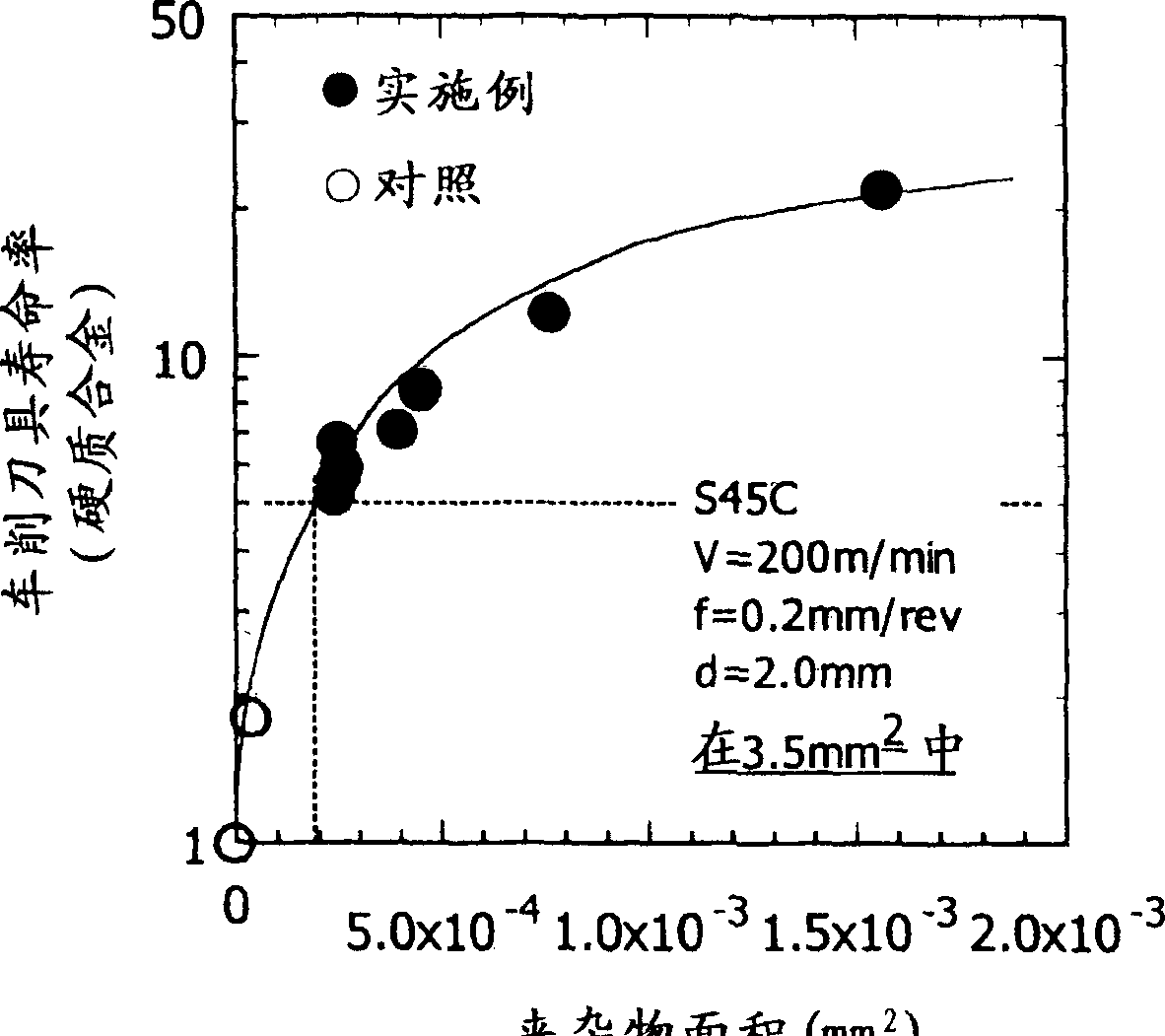

[0069] In the following examples, those with uppercase letters (A1, B1...) are operational examples, and those with lowercase letters (a1, b1...) are comparative examples. The prepared alloy was cast into ingots, from which 72 mm diameter round bar test pieces were cut for testing. Test methods and standards are described below. [area occupied by composite inclusions]

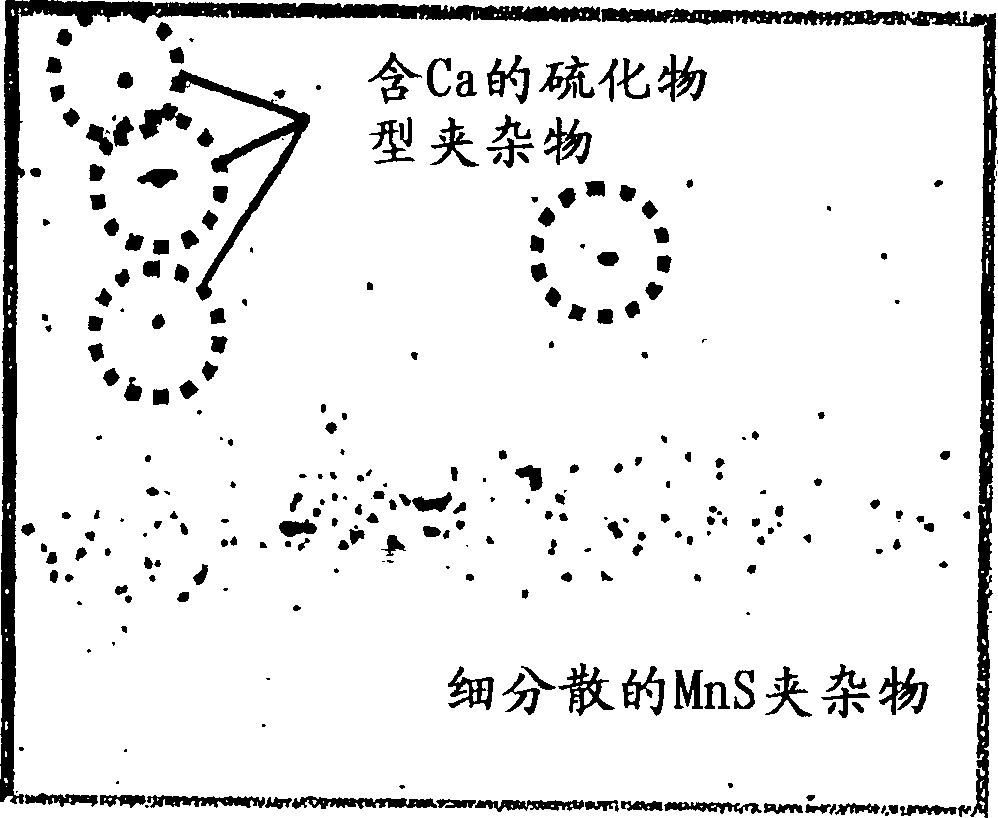

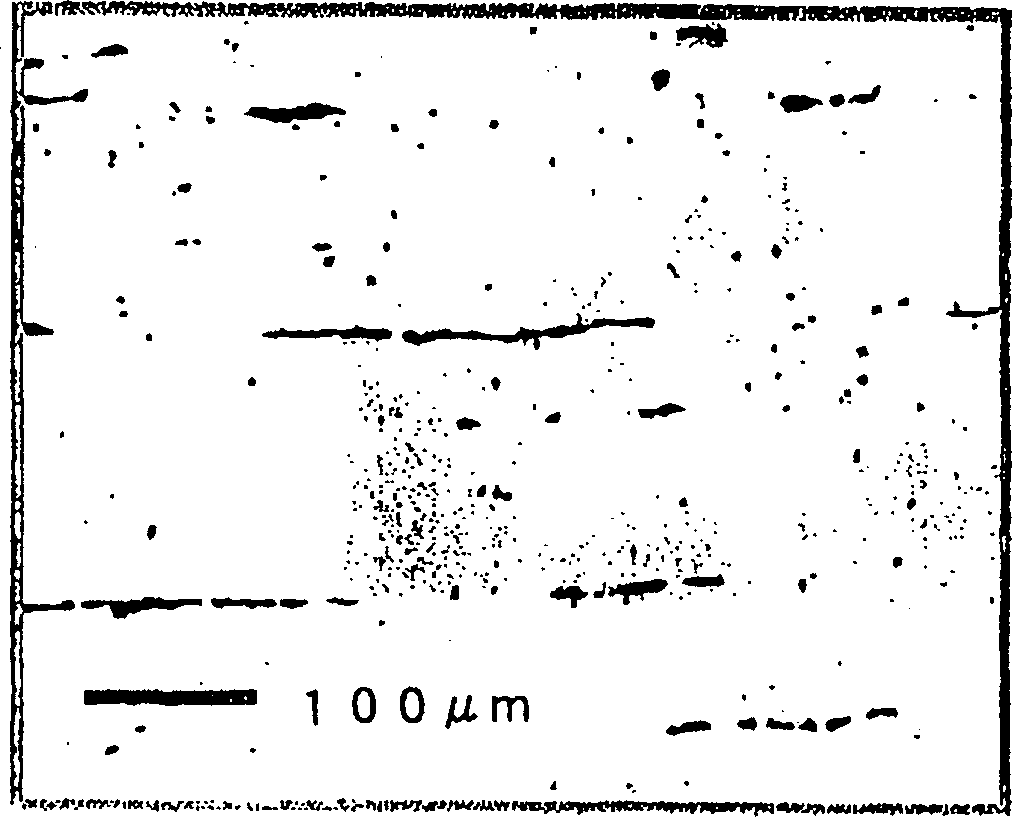

[0070] When composite inclusions or sulfide-type inclusion particles containing Ca and close to oxide-type inclusion particles, every 3.5mm 2 Occupies 2.0×10 -4 mm 2 or more area marked "yes", the opposite case, "no". [area percentage of composite inclusions]

[0071] The whole sulfide-type inclusions in the micrograph (magnification 200) are divided into simple sulfide-type inclusions and composite inclusions. Find the percentage of area occupied by composite inclusions. [Machinability]

[0072] Carry out turning of carbide tools under the following conditions: Cutting speed: 200m / min Feed speed: 0.2mm...

Embodiment 2

[0079] The same production process and machinability test as in Example 1 were applied to S15C steel. Alloy compositions are shown in Table 5 (Working Example) and Table 6 (Comparative Example), and test results are shown in Table 7 (Working Example) and Table 8 (Comparative Example). Example 3

[0080] The same production process and machinability test as in Example 1 were applied to S55C steel. Alloy compositions are shown in Table 9 (Working Example) and Table 10 (Comparative Example), and test results are shown in Table 11 (Working Example) and Table 12 (Comparative Example). Example 4

[0081] The same production process and machinability test as in Example 1 were applied to SCR415 steel. Alloy compositions are shown in Table 13 (Working Example) and Table 14 (Comparative Example), and test results are shown in Table 15 (Working Example) and Table 16 (Comparative Example). Example 5

[0082] The same production process and machinability test as in Example 1 were a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com