Reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable capacity machinery, electromechanical devices, mechanical equipment, etc., can solve the problems of reduced compression efficiency, inconsistent center, increased manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the reciprocating compressor of the present invention will be described below with reference to the accompanying drawings.

[0051] There are several embodiments of the reciprocating compressor of the present invention, the most preferred embodiments of which are described below.

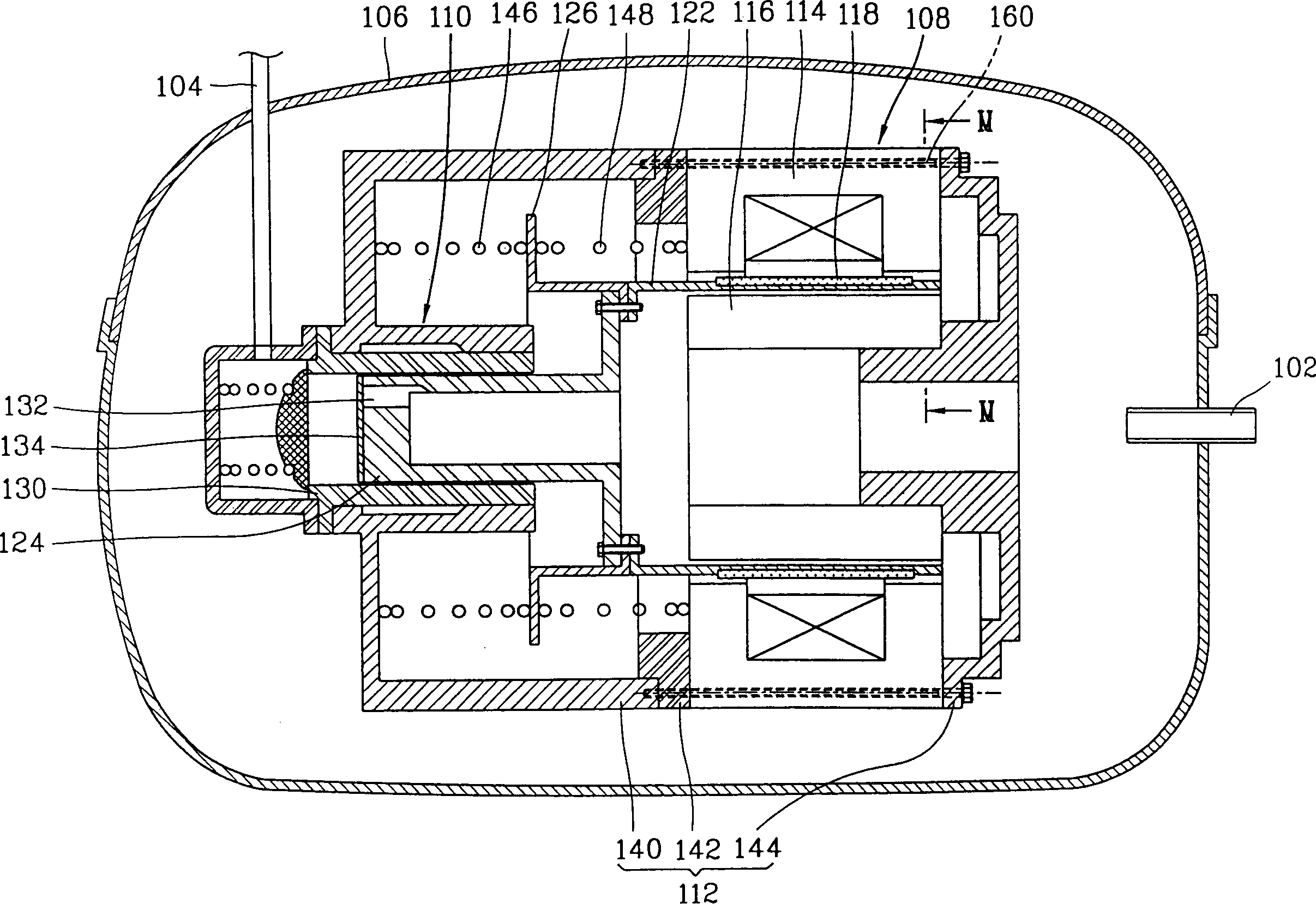

[0052] Figure 4 is a sectional view showing a reciprocating compressor according to the present invention.

[0053] The reciprocating compressor according to the present invention includes a hermetic casing 2; a motor unit 4, which is arranged in the casing 2 and generates a reciprocating force when the power is turned on; a compression unit 6, which receives the reciprocating force generated by the motor unit 4 and performs a compression operation of fluid; and a support unit 8 for supporting the motor unit 4 and the compression unit 6 .

[0054] A suction pipe 9 for sucking fluid and a discharge pipe 10 for discharging compressed fluid are engaged with the hermet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com