High-pressure rotary bed gas-liquid mass-transferring and reaction equipment in superheavy force field

A reaction equipment, gas-liquid mass transfer technology, applied in the chemical method of reacting liquid and gas medium, chemical/physical/physical-chemical mobile reactor, pressure vessel/vacuum vessel, etc. Eddy current heat, leakage, demagnetization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

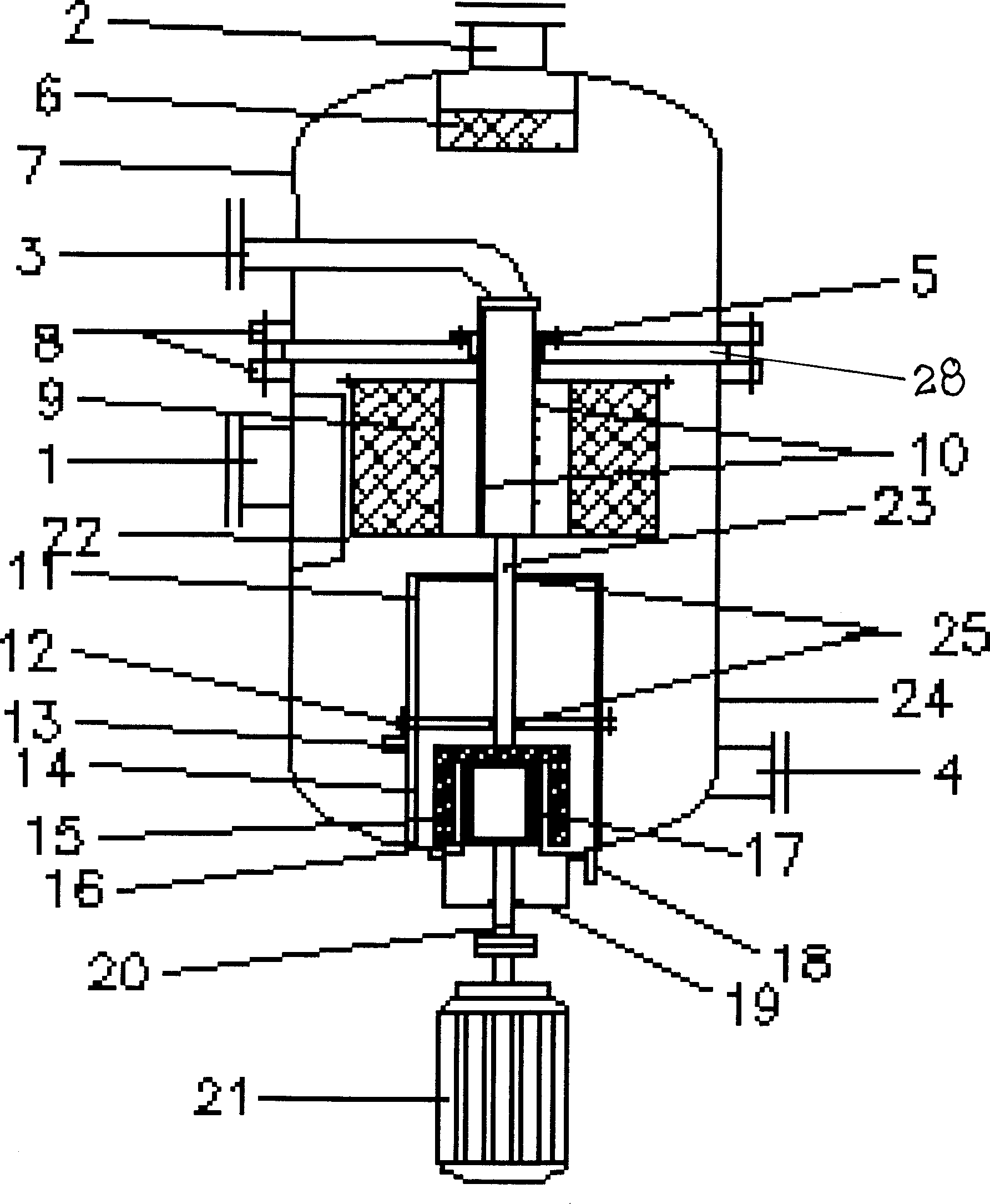

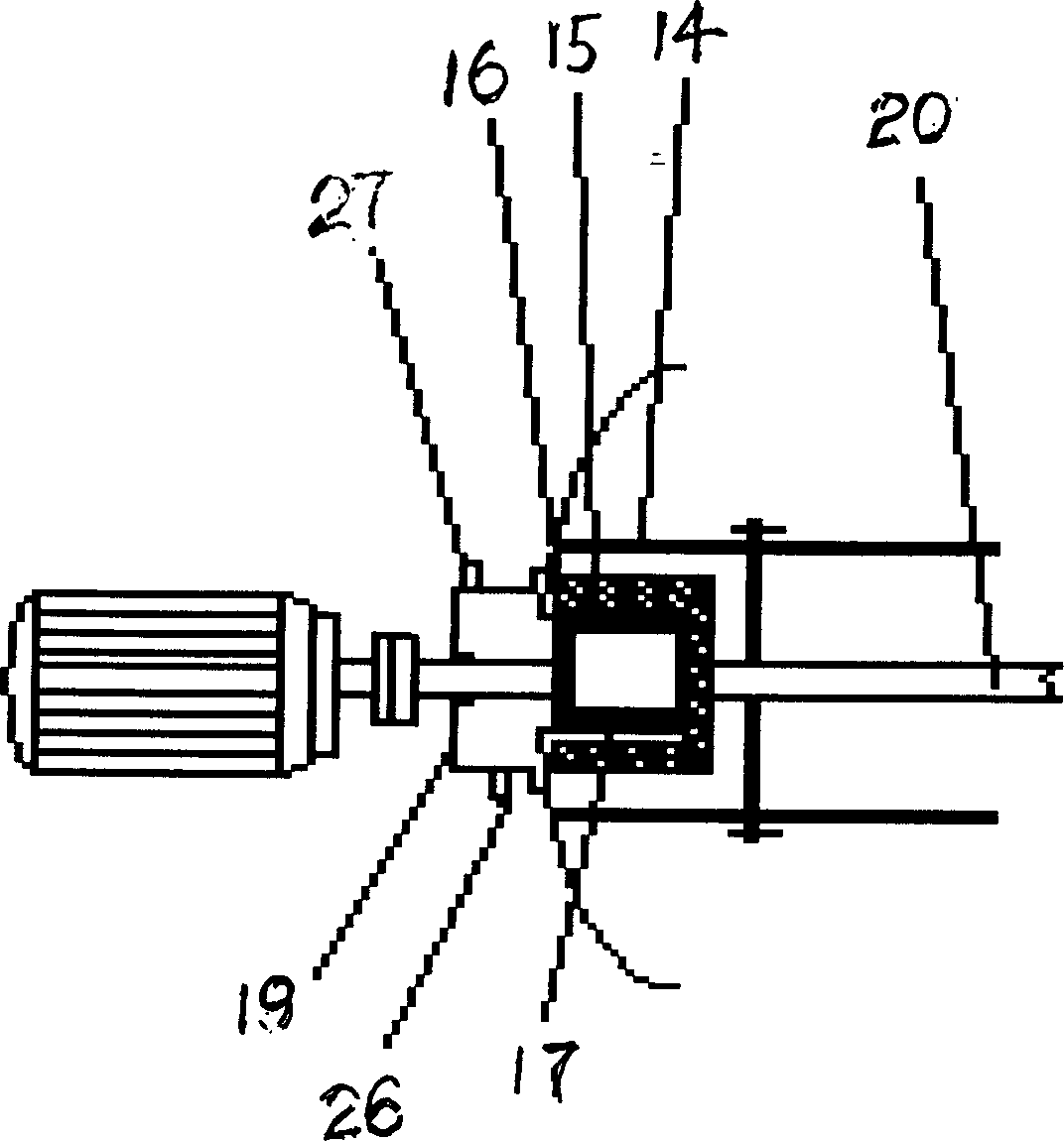

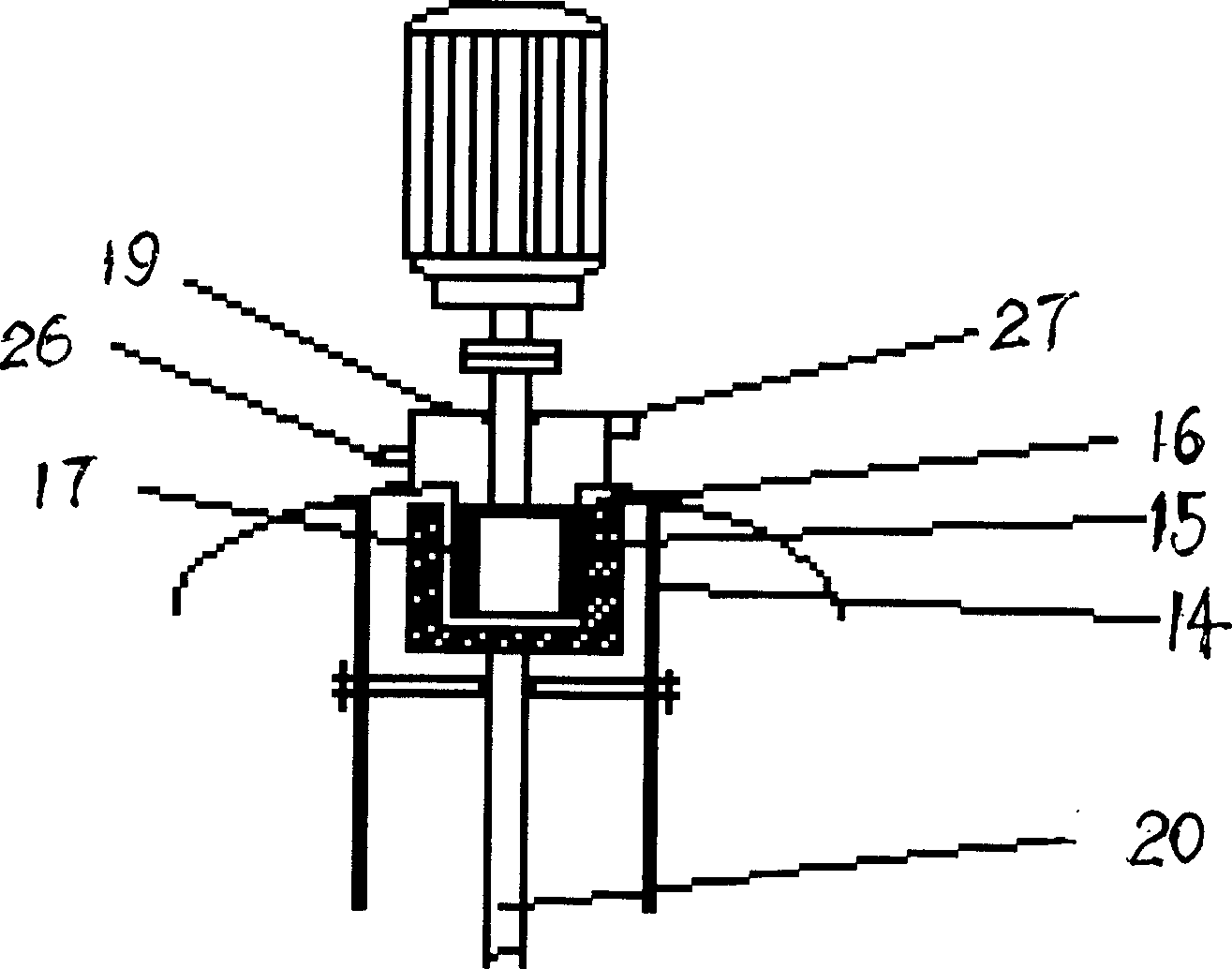

[0020] attached below figure 1 The present invention will be described in detail.

[0021] as attached figure 1 As shown, 1 is a gas inlet pipe, and the gas inlet pipe is arranged along the tangent of the shell. There is an arcuate gas deflector 22 with small holes at the gas inlet. Its function is to prevent the radial deviation caused by the direct blowing of the gas to the rotor, which will cause partial wear of the support bearing or bushing and reduce the operating cycle of the equipment; 2. Gas outlet; 3 is the liquid inlet; 4 is the liquid outlet; 28 is the gas partition between the rotor 9 and the gas outlet; 5 is the dynamic seal between the rotor and the gas partition 28, which is sealed by a float valve or a liquid ring Seal or packing seal or mechanical seal or labyrinth seal, its function is to prevent gas short circuit from reducing mass transfer and reaction effect; 6 is high-efficiency foam trapping layer; 7 is oval upper head; 8 is high pressure flange; 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com