Manufacturing method for raising new property of semiconductor element

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as data disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

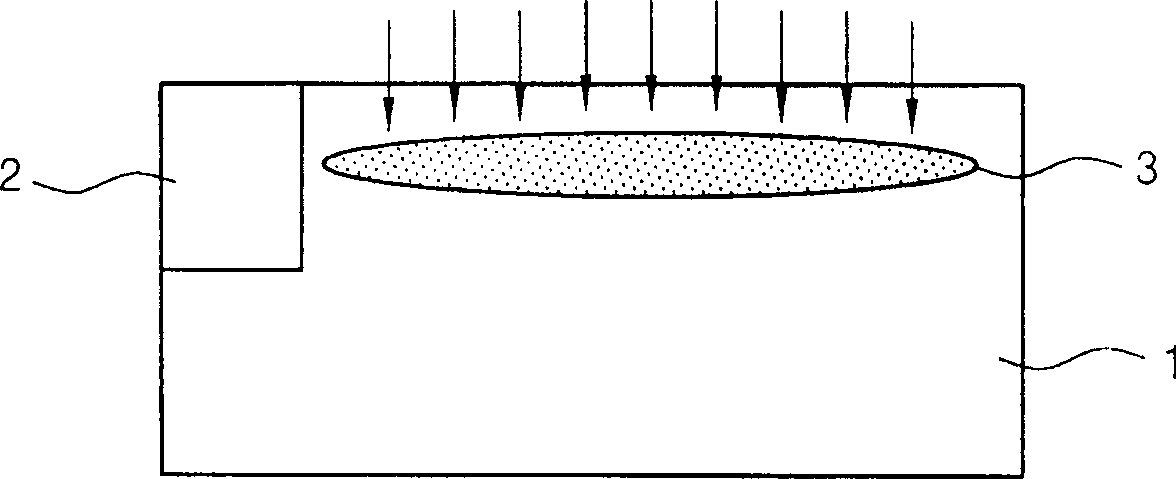

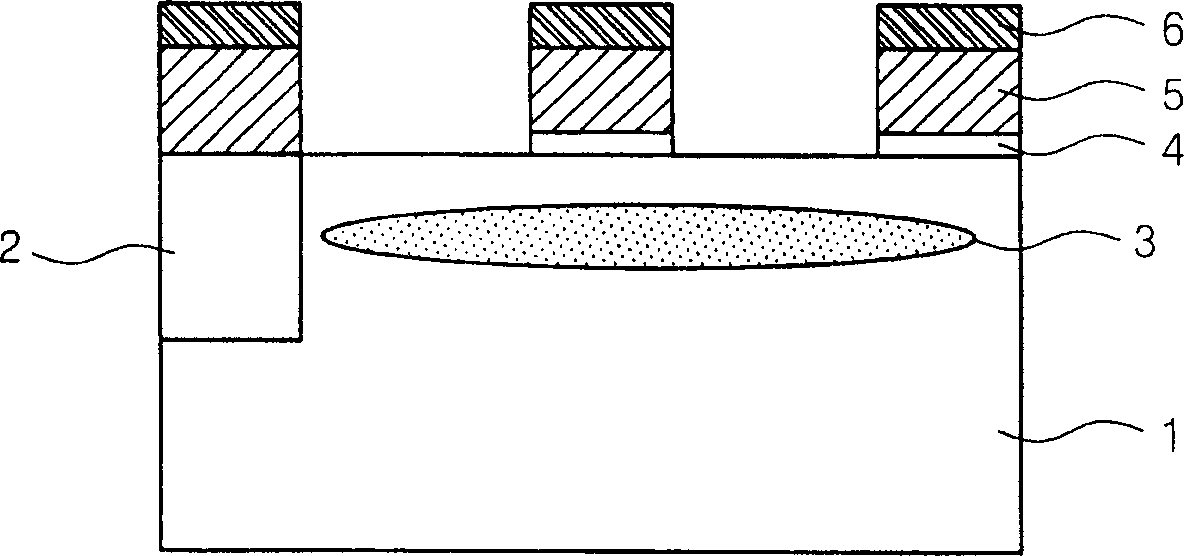

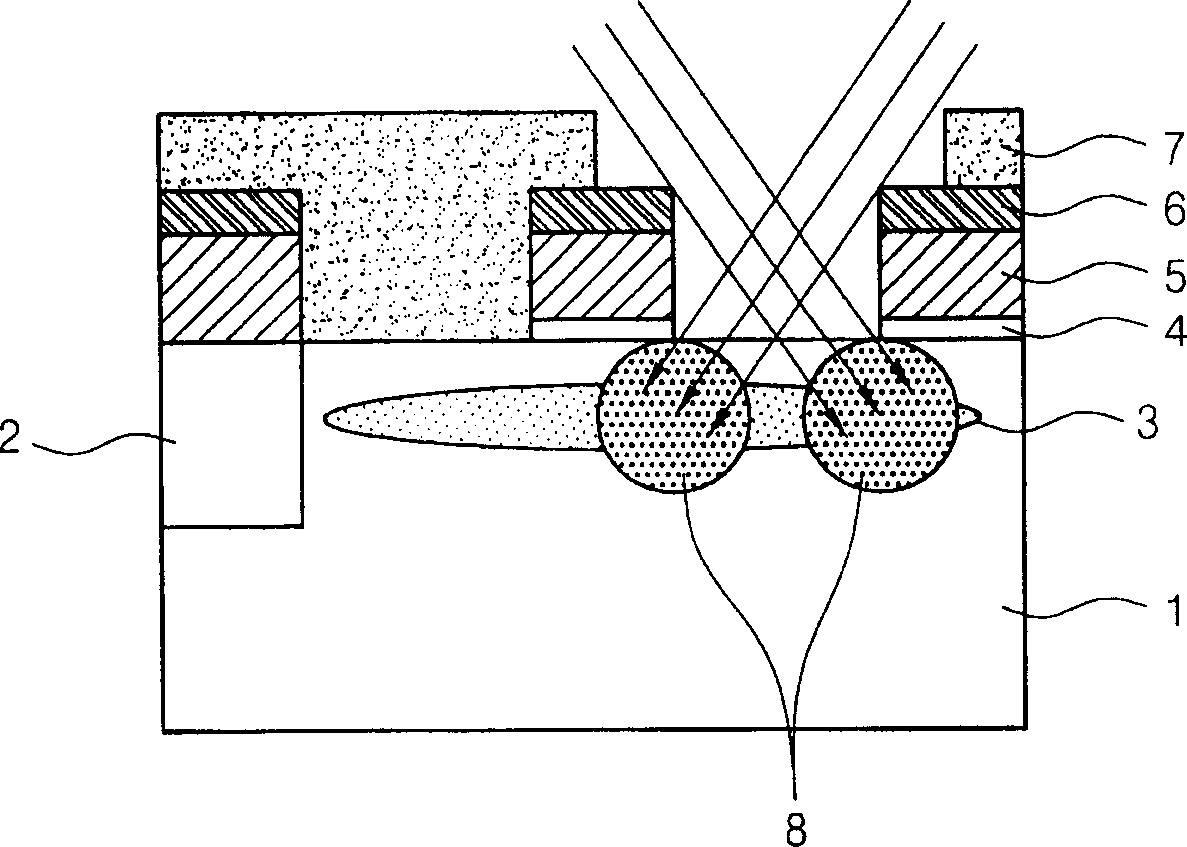

[0017] 1a to 1d are cross-sectional views for explaining the steps of the method of manufacturing a semiconductor element according to the embodiment of the present invention, and the description is as follows.

[0018] Referring to FIG. 1a, a trench-type element isolation film 2 defining its active region is formed on a semiconductor substrate 1 at an appropriate place by a known STI (Shallow Trench Isolation) process. Next, in order to adjust the threshold voltage (Vt) of the cell transistor, a predetermined impurity such as boron is ion-implanted into the active region of the semiconductor substrate 1 . At this time, the ion implantation for the adjustment of the threshold voltage is preferably performed within a range of 0 to 90% of the concentration of all dopants necessary for the adjustment of the threshold voltage. Symbol 3 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com