Welding method and welding device

A welding method and welding device technology, applied in welding equipment, non-electric welding equipment, electrical components, etc., can solve problems such as uneven size, cut leads, and inability to guarantee welding quality, and achieve constant quality and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

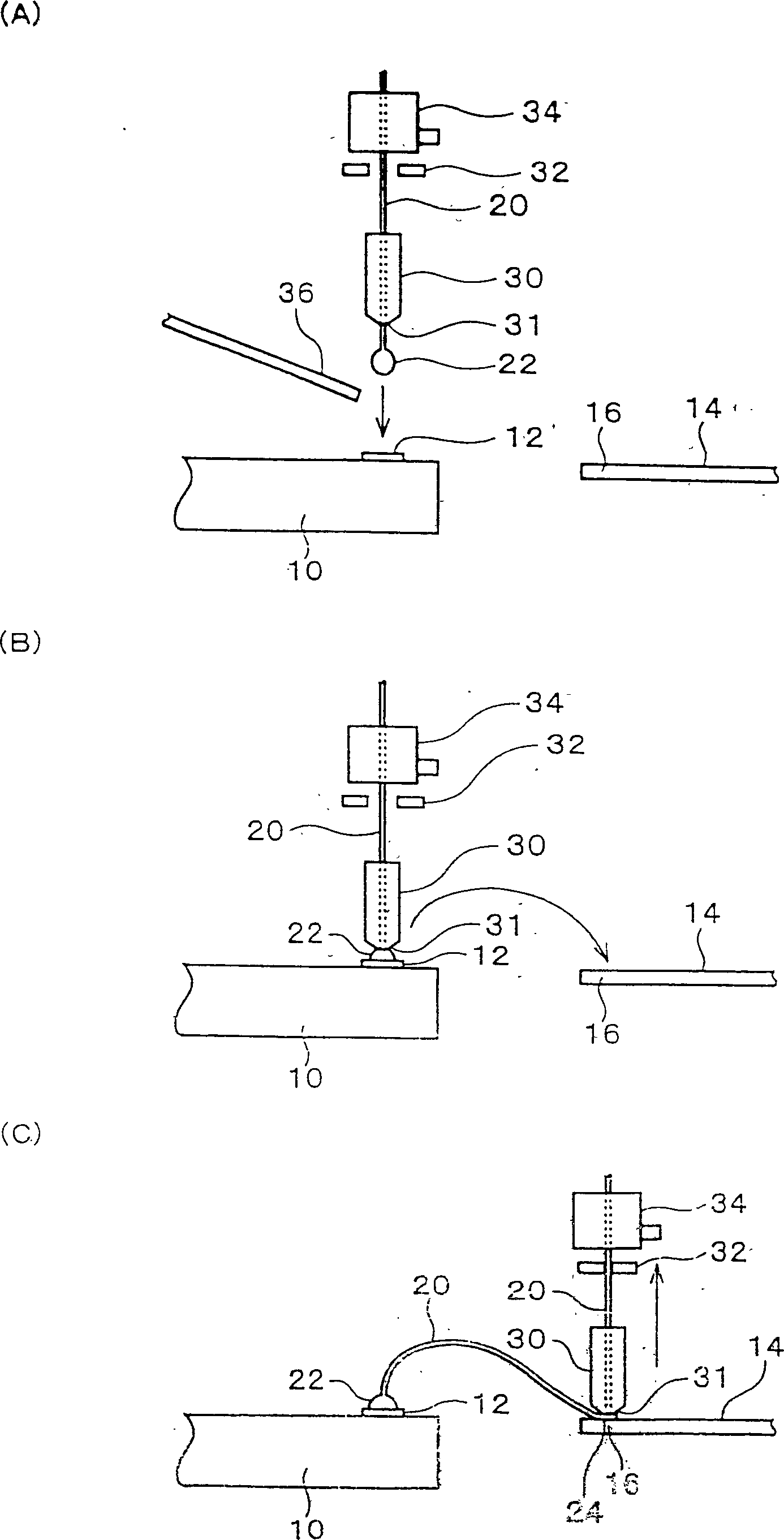

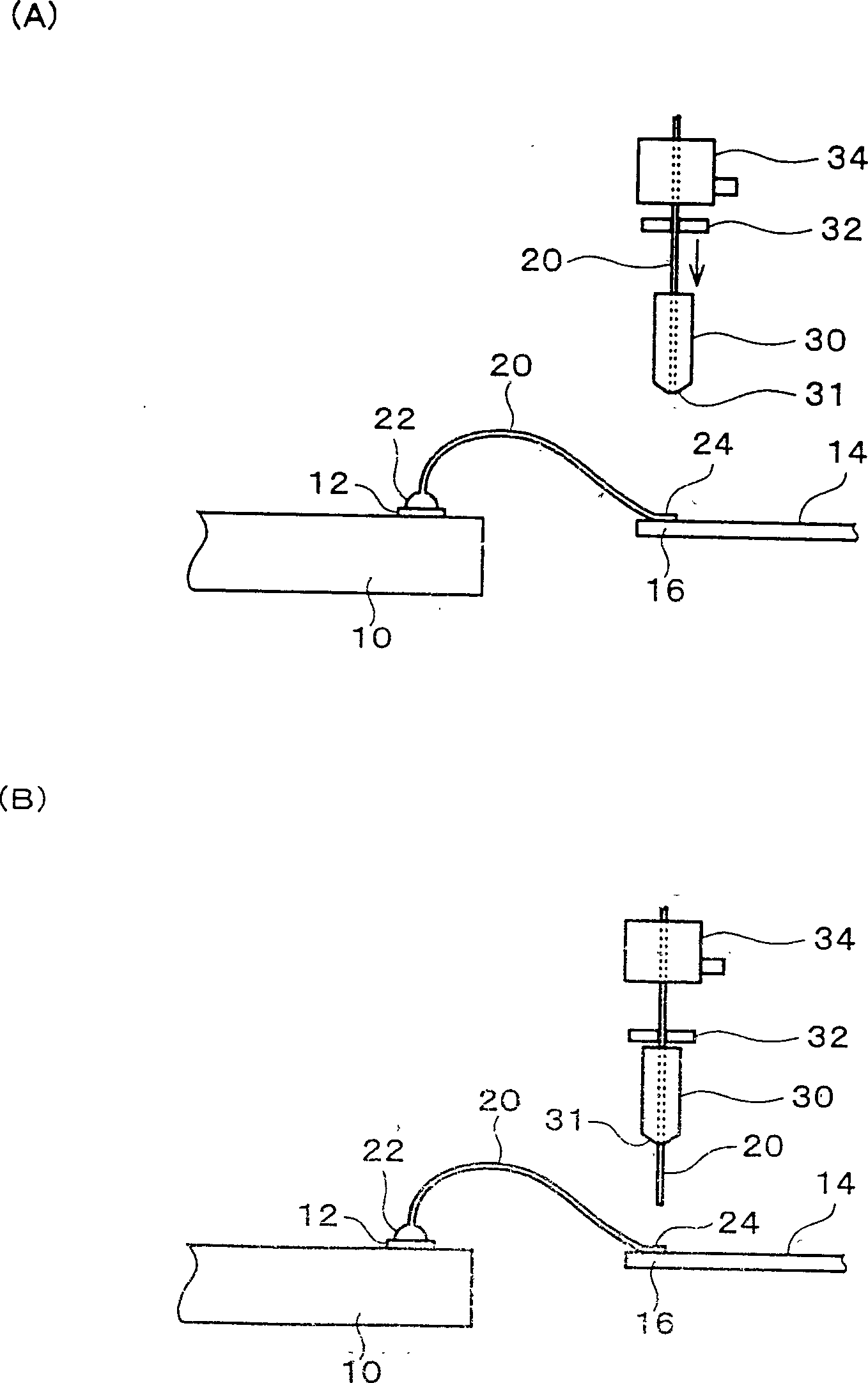

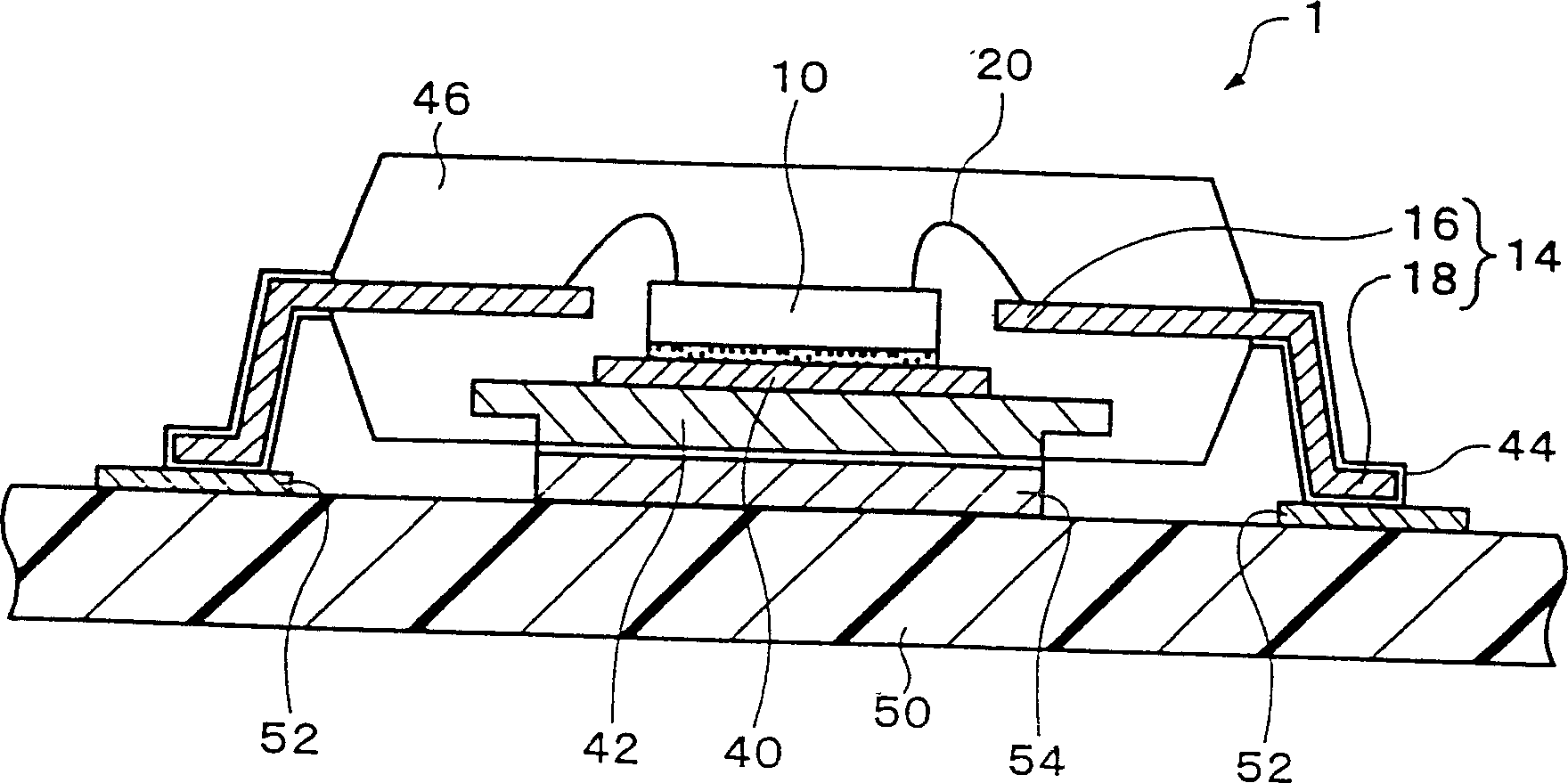

[0054] figure 1 A~ figure 2 B is a diagram showing a semiconductor device manufacturing method and manufacturing apparatus (also referred to as a wire bonding method and a wire bonding apparatus) according to the first embodiment of the present invention.

[0055] First, if figure 1 As shown in A, a semiconductor chip 10 on which a plurality of pads 12 and a plurality of leads 14 are formed is prepared.

[0056]The semiconductor chip 10 has a surface (active surface) on which an integrated circuit is formed. The integrated circuit is formed on the surface of the largest area of the semiconductor chip 10 which is a rectangular parallelepiped. The pads 12 are often formed on the side of the surface of the semiconductor chip 10 on which the integrated circuit is formed. The pads 12 are formed of aluminum-based or copper-based metals, and are often formed as a flat thin layer on the semiconductor chip 10 . Also, on the semiconductor chip 10, a passivation film (not shown) ...

no. 2 Embodiment approach

[0083] Figure 4 A~ Figure 5 B is a diagram showing a semiconductor device manufacturing method and manufacturing apparatus (also referred to as a bump forming method and a bump forming apparatus) according to the second embodiment of the present invention. In this embodiment mode, the semiconductor device manufacturing apparatus described in the above-mentioned embodiment mode can be used. In addition, in this embodiment, any one of the contents described in the above embodiments can be selectively applied.

[0084] First, if figure 1 As shown in A, a semiconductor wafer 60 is prepared. The semiconductor wafer 60 includes a surface (active surface) on which integrated circuits are formed. Then, a plurality of pads 62 are formed on the side of the semiconductor wafer 60 on which the integrated circuits are formed. In addition, a passivation film (not shown) may be formed on the semiconductor wafer 60 other than the pads 62 . In the present embodiment, the bump formation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com