Method for preparing the carbide coat on surface of metal alloy basal body containing carbon

A technology of metal alloys and carbides, which is applied in the field of preparation of carbide coatings on the surface of carbon-containing metal alloy substrates, can solve problems such as low production efficiency, low coating bonding strength, and demanding production equipment, and achieve improved wear resistance , Good controllability of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

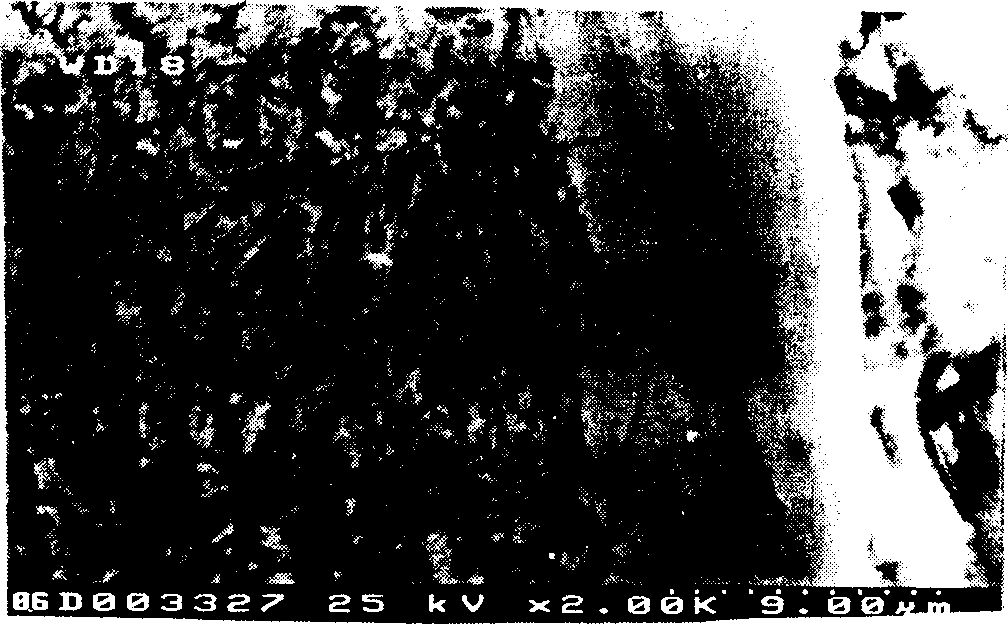

[0024] see figure 1 . figure 1 The cross-sectional morphology of the prefabricated Cr coating converted to chromium carbide coating on the surface of T10 steel. According to the method of the present invention, the Cr coating is prefabricated on the surface of the T10 steel by electroplating, and kept at 1100° C. for 3 hours, so that the Cr coating is transformed into a chromium carbide coating.

Embodiment 2

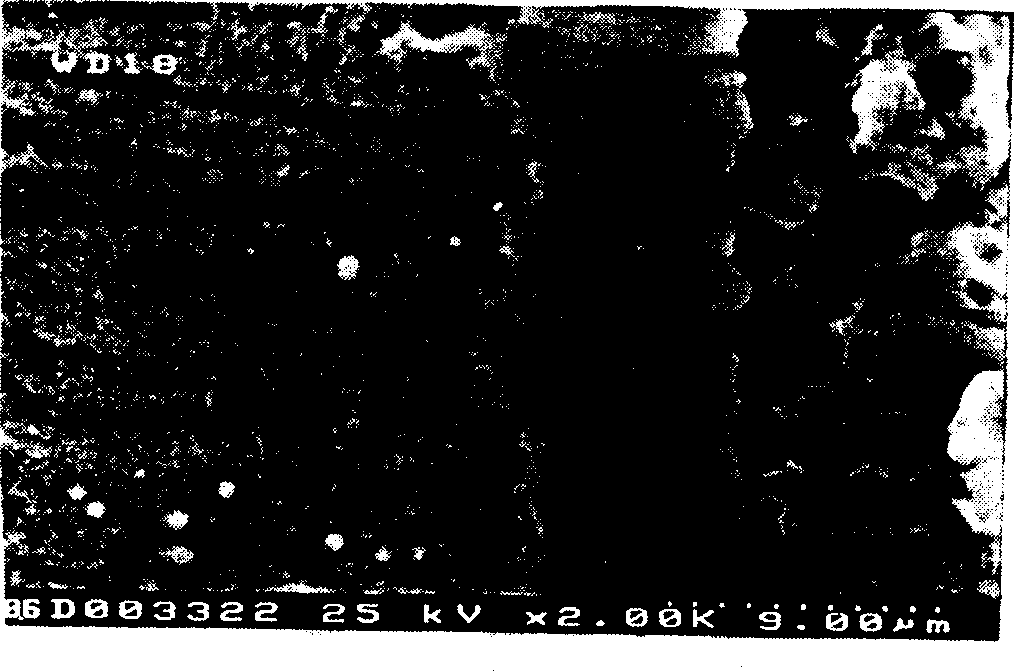

[0026] see figure 2 . figure 2 The cross-sectional morphology of the prefabricated Cr coating converted to chromium carbide coating on the surface of GCr15 bearing steel. According to the method of the present invention, the Cr coating is prefabricated on the surface of the GCr15 bearing steel by electroplating, and kept at 900° C. for 3.5 hours to convert the Cr coating into a chromium carbide coating.

Embodiment 3

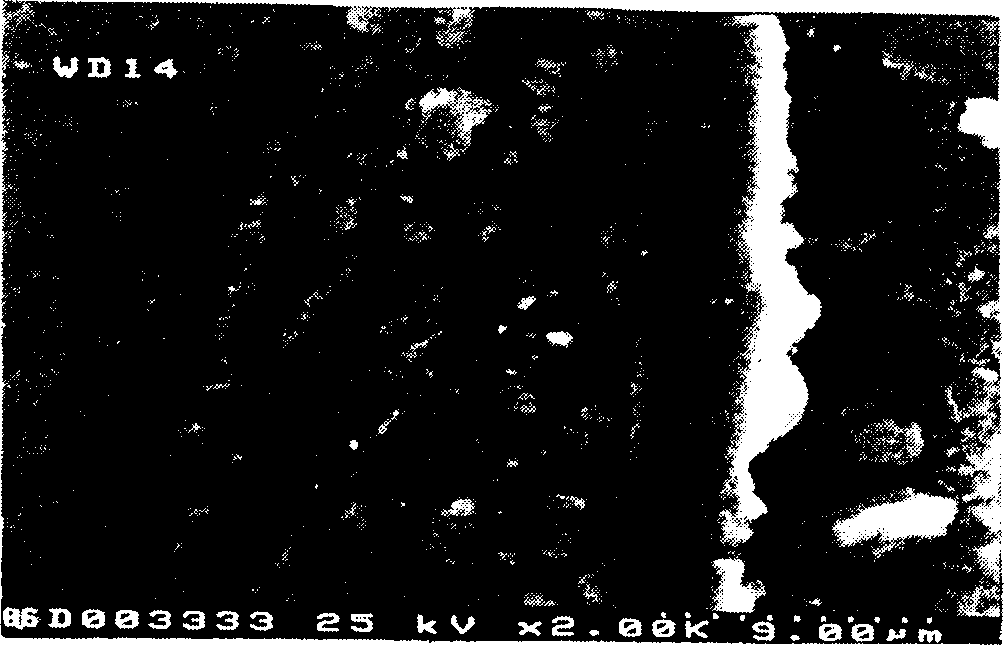

[0028] see image 3 . image 3 The cross-sectional morphology of the prefabricated Cr coating converted to chromium carbide coating on the surface of Cr12MoV die steel. According to the method of the present invention, the Cr coating is prefabricated on the surface of the Cr12MoV die steel by electroplating, and the temperature is kept at 1000° C. for 3 hours, so that the Cr is transformed into a chromium carbide coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com