Detection device of super quick process

A detection device and ultra-fast process technology, which is applied in the direction of measuring time interval device, transmittance measurement, scattering characteristic measurement, etc., can solve the problem of not being able to measure the excitation process in detail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

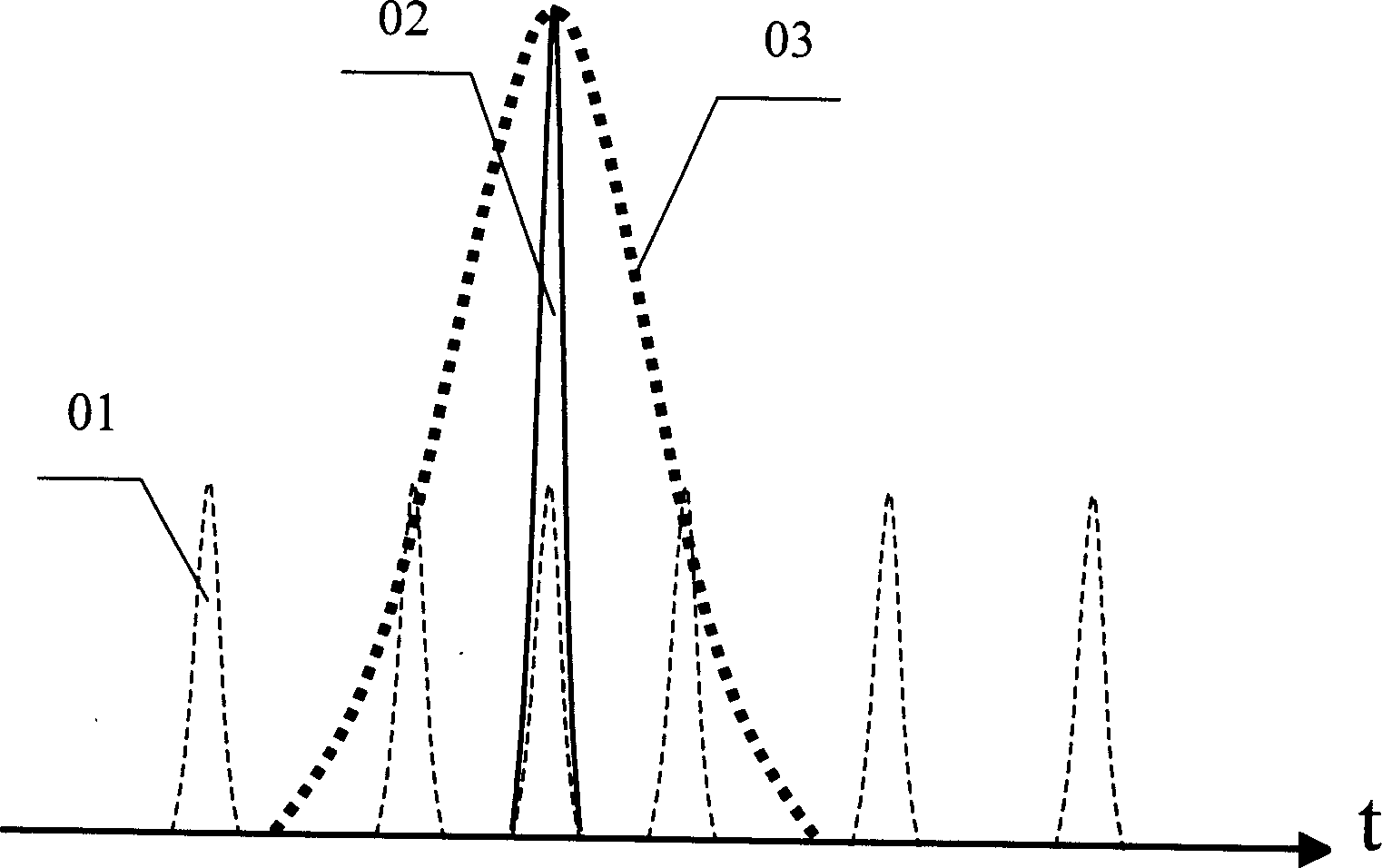

[0027] see first figure 1 with figure 2 . figure 1 is a schematic diagram of the relative delay time of pump light-probe light. The time is t, probe light pulse 01, pump light pulse 02 in the prior art, and pump light pulse 03 in the device of the present invention. In the prior art, the pulse width of the pump light and the probe light are the same, and the excitation process of the material cannot be carefully measured. It can be seen from the figure that the pump light pulse 03 of the present invention is several times that of the probe light pulse 01 . We can also use dispersive elements to expand the pulse width of the pump light to several tens of times, or even hundreds of times the pulse width of the probe light.

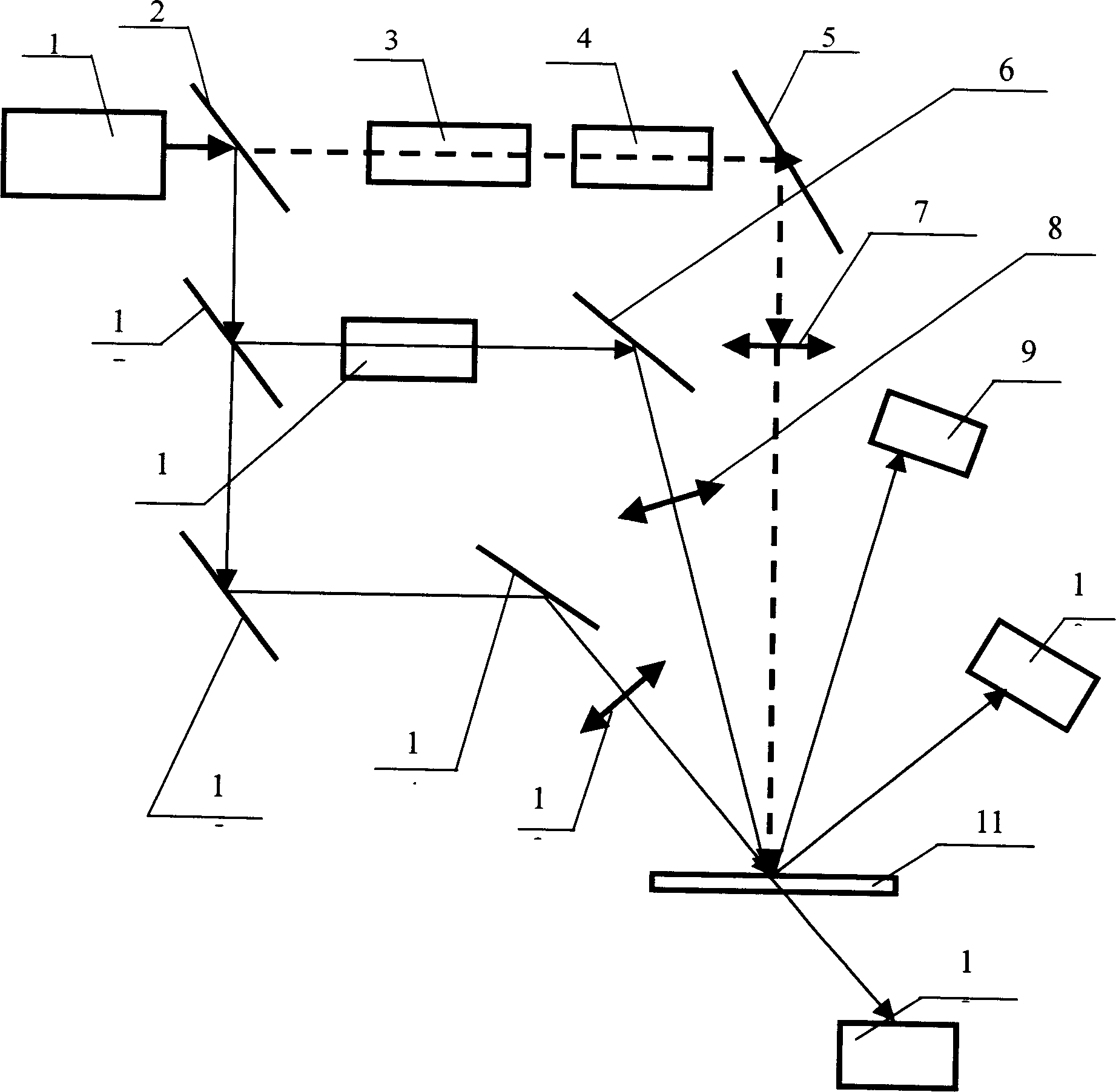

[0028] figure 2 It is a structural schematic diagram of the best embodiment of the ultrafast process detection device of the present invention. Its structure is as follows: light source 1 (generally a femtosecond laser pulse) is divided into a beam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com