LBJT (Lateral Bipolar Junction Transistor) containing field plate structure

A technology of bipolar transistors and field plates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of restricting the blocking voltage and high electric field strength of lateral bipolar transistors, achieve high blocking voltage, improve resistance Cut-off voltage level, enhanced depletion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

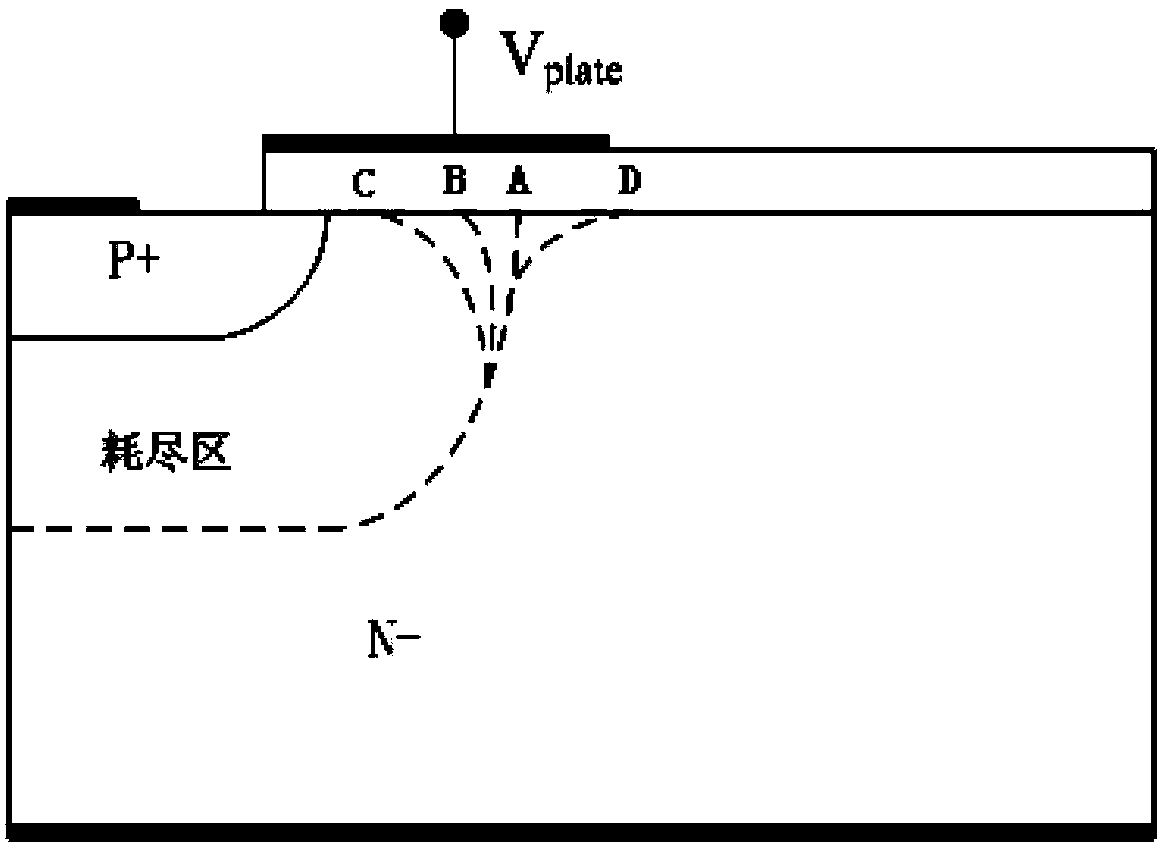

Problems solved by technology

Method used

Image

Examples

Embodiment 1

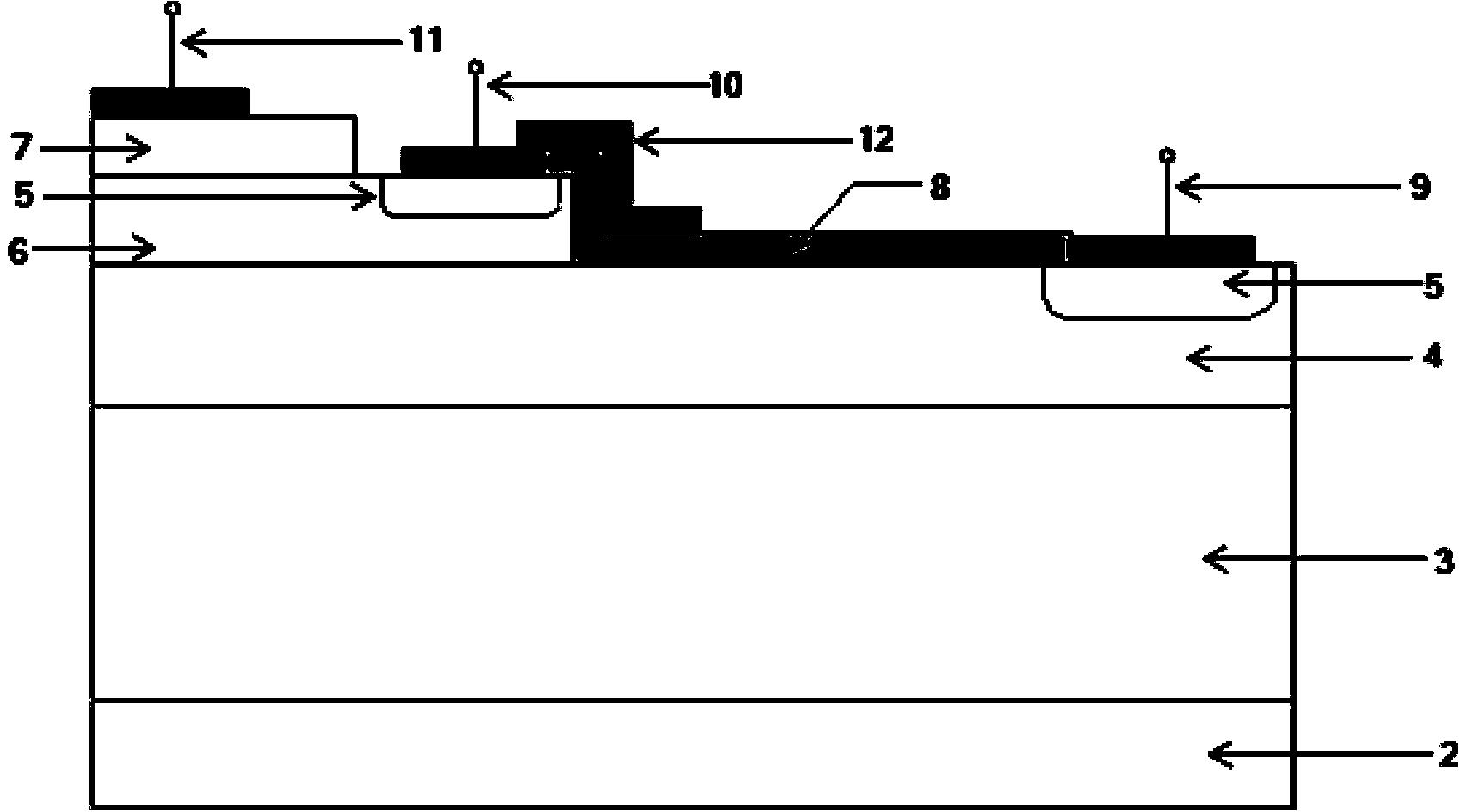

[0030] A specific implementation of the lateral bipolar transistor with field plate structure described in the present invention is given below, see figure 2 As shown, the lateral bipolar transistor with a base field plate structure in this embodiment includes a substrate 2, a buffer zone 3, a collector region 4, a base region 6, and an emitter region 7 from bottom to top, respectively. The ohmic contact region 5 is formed by ion implantation at the upper boundary of the collector region 4 and the base region 6, and metal deposition is performed on the collector region 4, the base region 6, and the emitter region 7 respectively. Metal electrodes are formed in a manner, the emitter 11 is located on the emitter region 7, the collector 9 is located on the ohmic contact region 5 of the collector region 4, and the base 10 is located between the ohmic contact region 5 of the base region 6 Above, a base field plate 12 is provided on the base region 6, an oxide layer 8 is provided on...

Embodiment 2

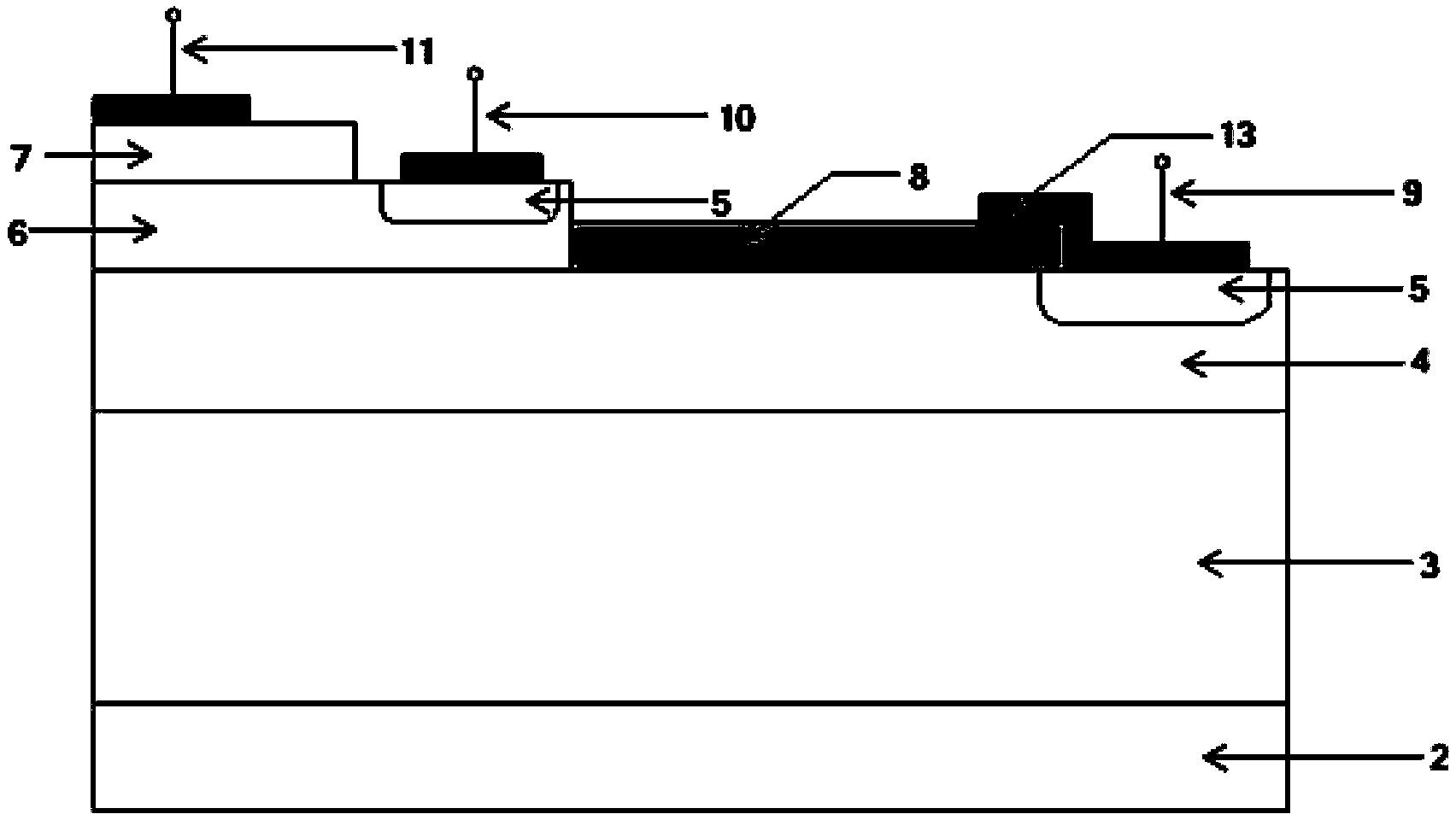

[0033] Another specific implementation of the lateral bipolar transistor with field plate structure described in the present invention is given below, see image 3 As shown, the lateral bipolar transistor with a collector field plate structure in this embodiment includes a substrate 2, a buffer zone 3, a collector region 4, a base region 6, and an emitter region 7 from bottom to top. The ohmic contact region 5 is formed by ion implantation at the upper boundary of the collector region 4 and the base region 6, and metal deposition is performed on the collector region 4, the base region 6, and the emitter region 7 respectively. Metal electrodes are formed in a manner, the emitter 11 is located on the emitter region 7, the collector 9 is located on the ohmic contact region 5 of the collector region 4, and the base 10 is located between the ohmic contact region 5 of the base region 6 Above, a collector field plate 13 is arranged on the collector region 4, an oxide layer 8 is arran...

Embodiment 3

[0036] Another specific implementation of the lateral bipolar transistor with field plate structure described in the present invention is given below, see Figure 4 As shown, the lateral bipolar transistor with an emitter field plate structure in this embodiment includes a substrate 2, a buffer zone 3, a collector region 4, a base region 6, and an emitter region 7 from bottom to top, respectively. The ohmic contact region 5 is formed by ion implantation at the upper boundary of the collector region 4 and the base region 6, and metal deposition is performed on the collector region 4, the base region 6, and the emitter region 7 respectively. Metal electrodes are formed in a manner, the emitter 11 is located on the emitter region 7, the collector 9 is located on the ohmic contact region 5 of the collector region 4, and the base 10 is located between the ohmic contact region 5 of the base region 6 An emitter field plate 14 is arranged on the emitter region 7, an oxide layer 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com