Coating compositions for modifying hard surfaces

A composition, hard surface technology, applied in the field of coatings containing nanoparticle systems, can solve problems such as reducing surface scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

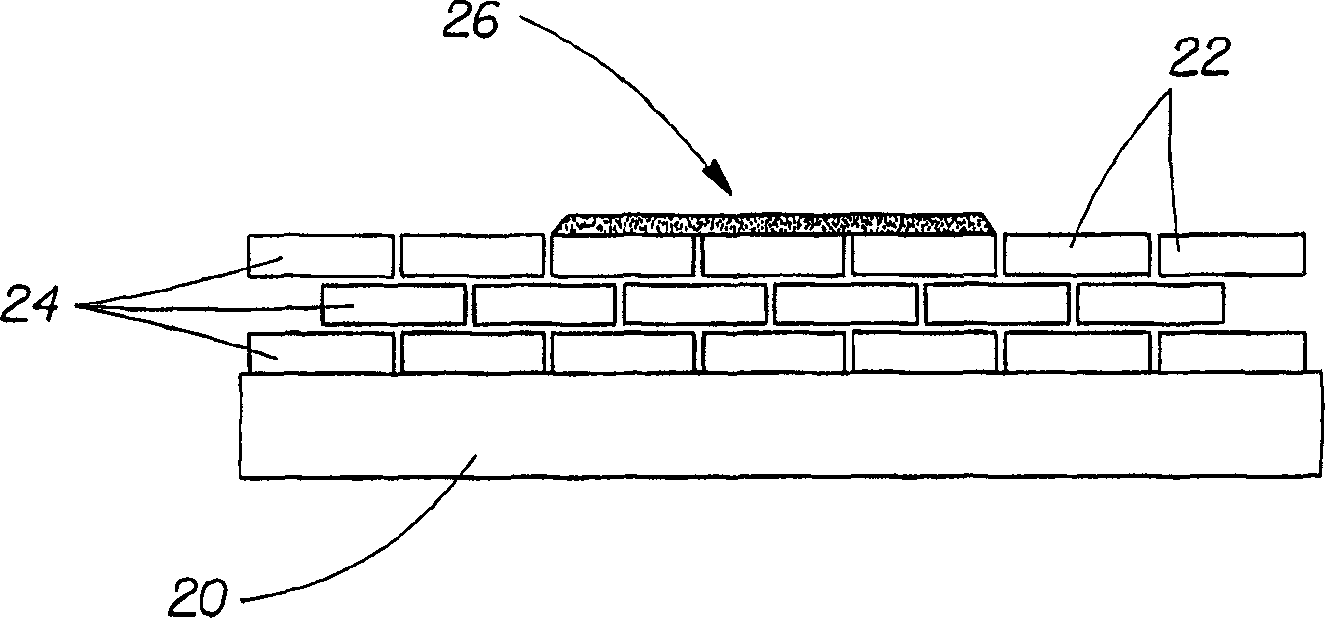

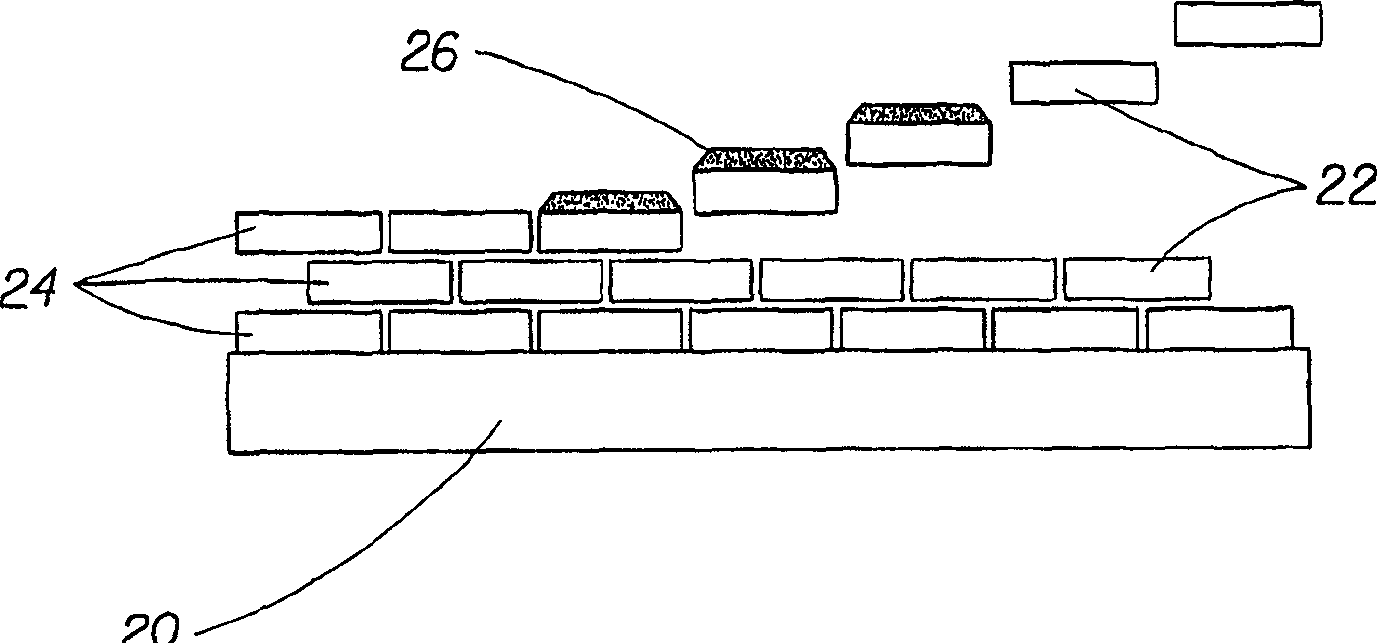

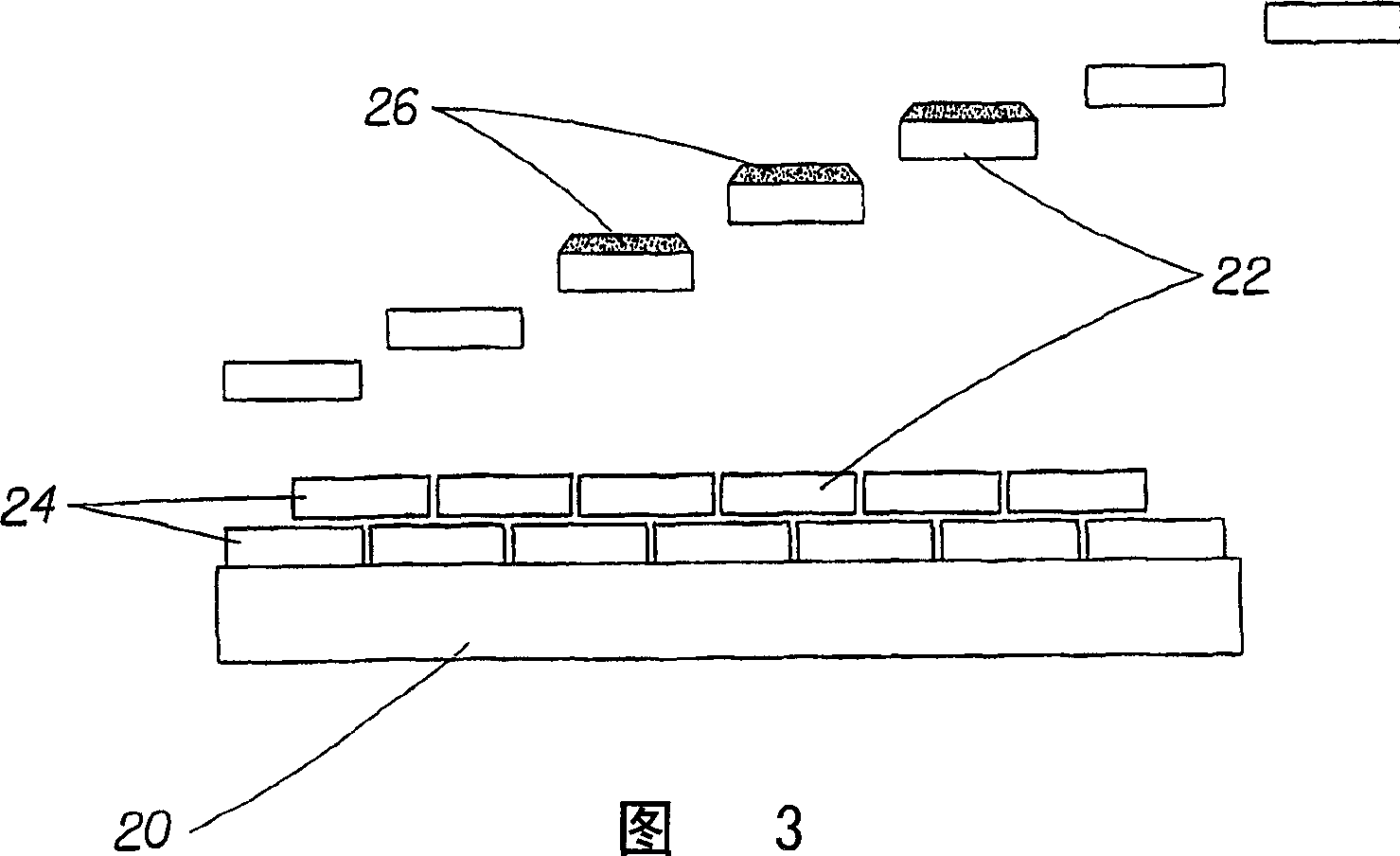

Image

Examples

Embodiment 1-14

[0293] The liquid coating compositions of the present invention are as follows, wherein the balance is water:

[0294] Examples#

Nanoparticles (Wt%)

Surfactant (Wt%)

1

Nanoclay (0.1)

Neodol 91-6(0.075)

2

Nanoclay (0.05)

Neodol 91-6(0.075)

3

Nanoclay (0.05)

Silwet L-77(0.025)

4

Nanoclay (0.1)

Q2-5211(0.025)

5

Nanoclay (0.05)

Q2-5211(0.025)

6

Nanoclay (0.03)

Q2-5211(0.1)

7

Nanoclay (0.1)

Tergitol 15-S-9(0.1)

8

Nanoclay (0.1)

Tergitol NP-9(0.1)

9

Nanoclay (0.1)

Neodol 91-8 (0.075)

10

Nanoclay (0.1)

Component A(0.2)

11

Nanoclay (0.2)

Component A(0.2)

12

Nanoclay (0.1)

Component B(0.2)

13

Nanoclay (0.1) 2

Neodol 91-6(0.075)

14

Disperal P2TM(0.1) 3

Neodol 91-6(0.075)

[0295] 1. The nanoclay can be any available synthetic hectorite clay, such as Lapon...

Embodiment 15-18

[0298] In the following examples, nanoclays and surfactants were used to formulate dispersants so that tap water could be used to prepare hard surface coating compositions:

[0299] Example

#

Nanoparticles (Wt%)

Surfactant (Wt%)

Dispersant (Wt%)

15

Nanoclay (0.1)

Neodol 91-6(0.075)

Polyacrylate 4500 MW (0.02)

16

Nanoclay (0.1)

Neodol 91-6(0.075)

Poly(acrylic acid / maleic acid) 2 (0.02)

17

Nanoclay (0.1)

Neodol 91-6(0.075)

Polyacrylate 2000 MW (0.02)

18

Nanoclay (0.1)

Neodol 91-6(0.075)

STPP(0.02)

[0300] 1. The nanoclay can be any available synthetic laponite clay, such as Laponite B from SouthernClay Products, Inc TM .

[0301] 2. MA:AA=4:6, MW=11000. Examples 19-26

Embodiment 19-26

[0302] The following are liquid coating compositions of the present invention, wherein the balance is water, wherein the coating composition can be applied to a surface, or optionally wherein the coating composition can be diluted with water to obtain a coating composition having a nanoparticle concentration of 0.1%:

[0303] Examples#

Nanoparticles (Wt%)

Surfactant (Wt%)

Dispersant (Wt%)

19

Nanoclay (1.6)

Q2-5211(0.8)

none

20

Nanoclay (0.8)

Q2-5211(0.4)

none

21

Nanoclay (0.8)

Neodol 91-6(0.6)

none

22

Disperal P2 TM (10)

Neodol 91-6(7.5)

none

23

Nanoclay (5.0)

Neodol 91-6(3.75)

Polyacrylate 4500

MW(1.0)

24

Nanoclay (5.0)

Neodol 91-6(3.75)

Poly(acrylic acid / maleic acid) 3

(1.0)

25

Nanoclay (1.0)

Neodol 91-6(0.75)

Polyacrylate 4500

MW(0.2)

26

Nanoclay (1.0)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com