Hydraulic lift energy-saving control system with hydraulic transformer

An energy-saving control system and hydraulic transformer technology, applied in elevators, transportation and packaging, etc., can solve the problems of high system cost and large installed power, and achieve real-time control, reuse, and fast dynamic response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

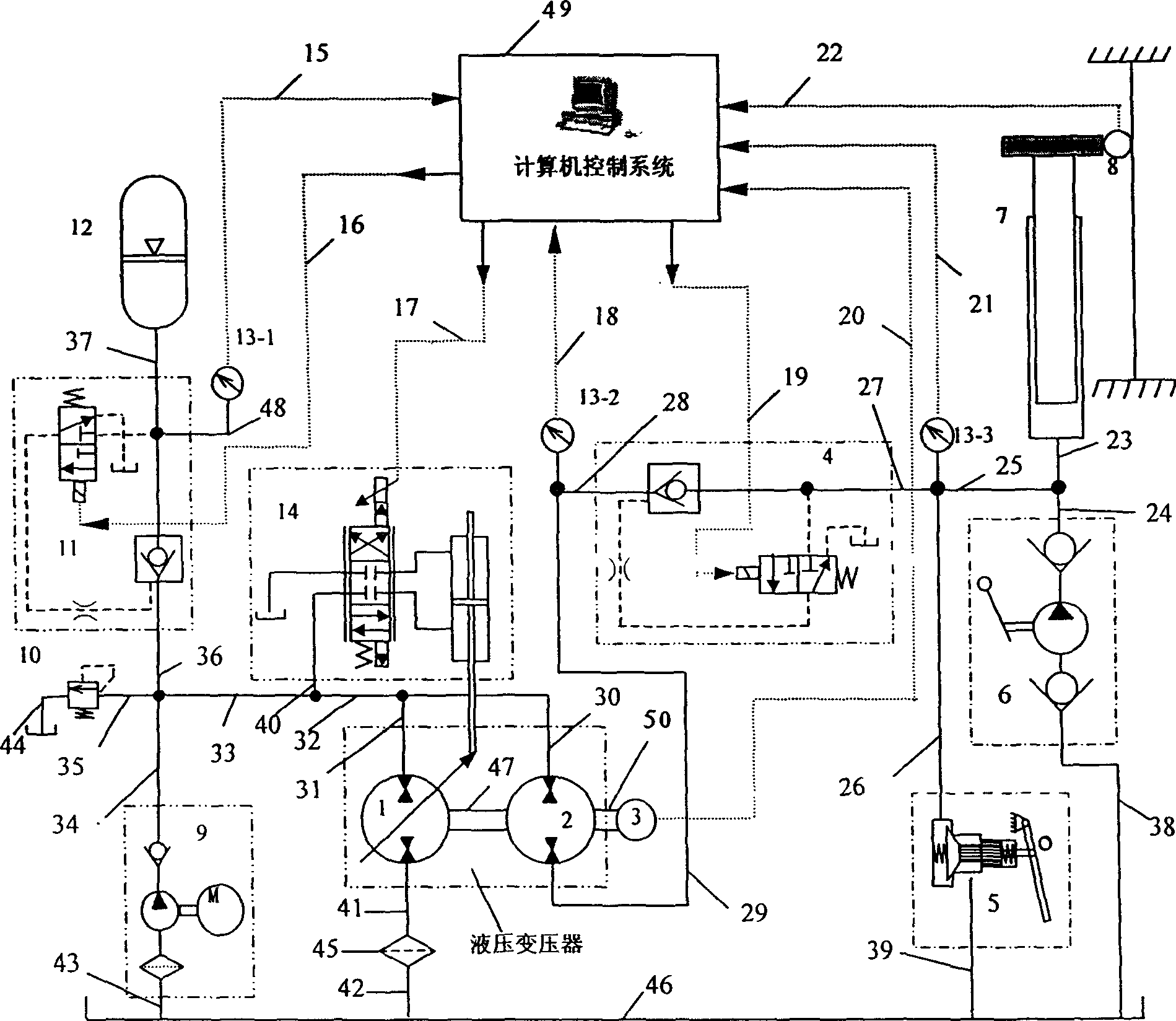

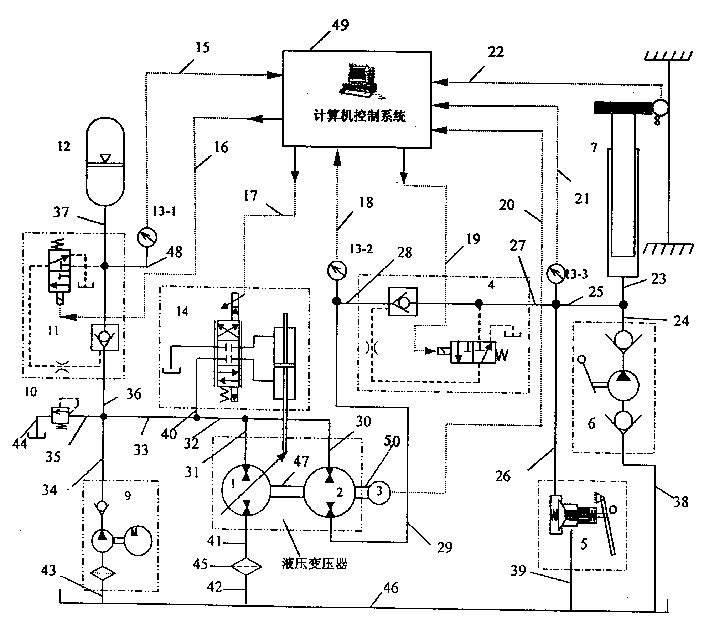

[0012] The accompanying drawing is a structural schematic diagram of a hydraulic elevator energy-saving control system using a hydraulic transformer, wherein: 1 is a variable pump / motor, one end is connected to a filter 45 through a pipeline 41, and an oil tank 46 is connected through a pipeline 42, and one end is connected through a pipeline 31 and The pipelines 32 and 30 are connected, and are coaxially connected with the quantitative pump / motor 2 through a coupling 47. The 2 is a quantitative pump / motor, one end is connected with the pipelines 31 and 32 through the pipeline 30, and the other end is connected with the pipeline 29 through the pipeline 29. The pressure sensor 13-2 is connected, 3 is the speed measuring photoelectric encoder, which is installed on the other shaft end of the quantitative pump / motor 2 through another coupling (50), 4 is the hydraulic control check valve of the main circuit, and one end passes through the pipeline 28 is connected with the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com