Process for preparing Fuller-ene

A fullerene and raw material technology, applied in the field of fullerene preparation, can solve the problems of high cost of raw materials and preparation equipment, low yield, and inability to synthesize in large quantities at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

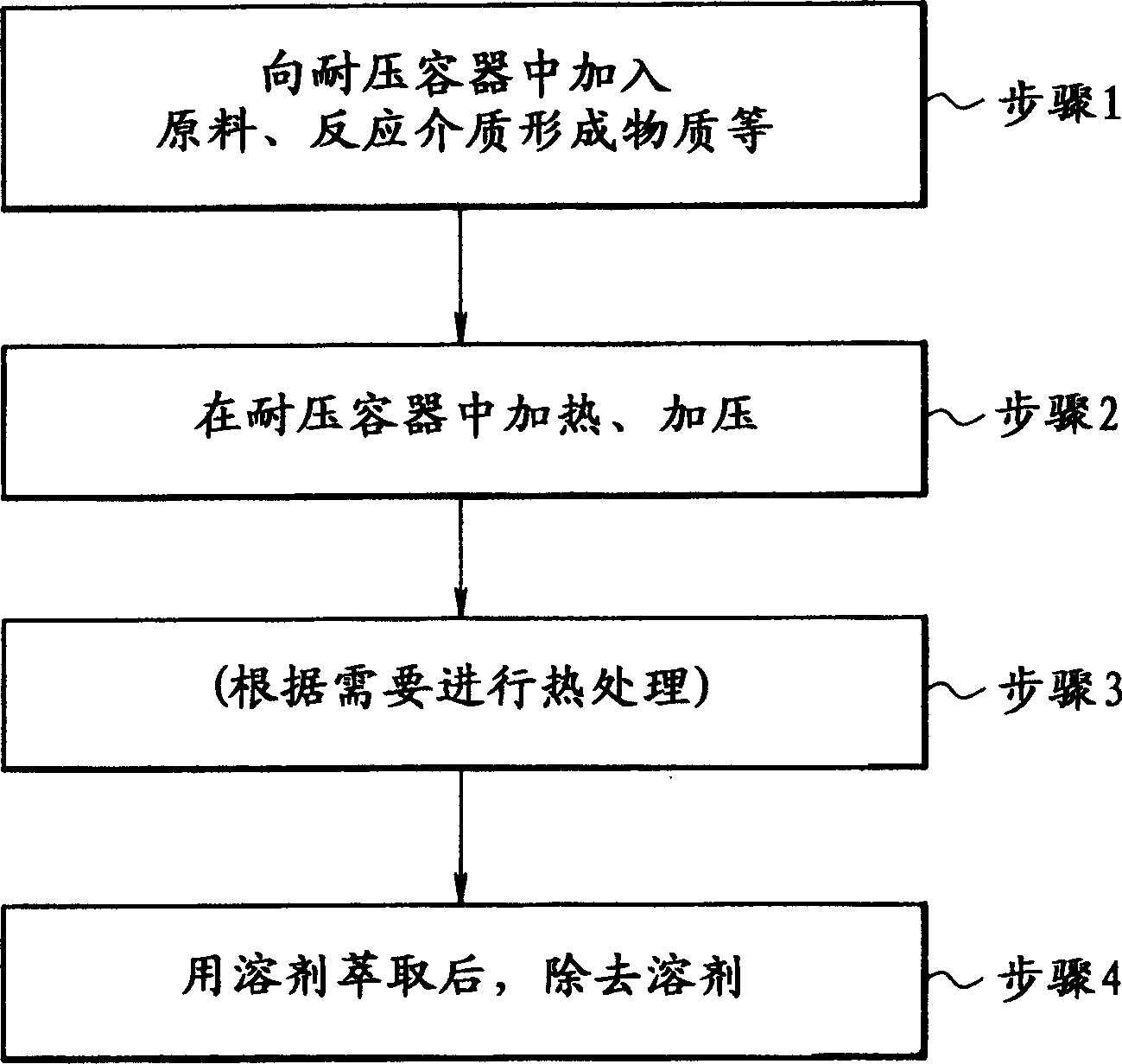

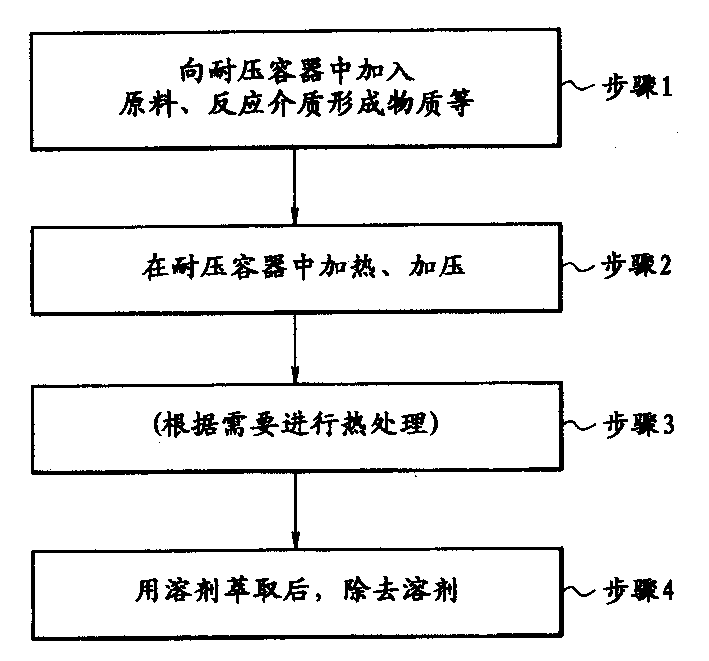

Method used

Image

Examples

Embodiment 1

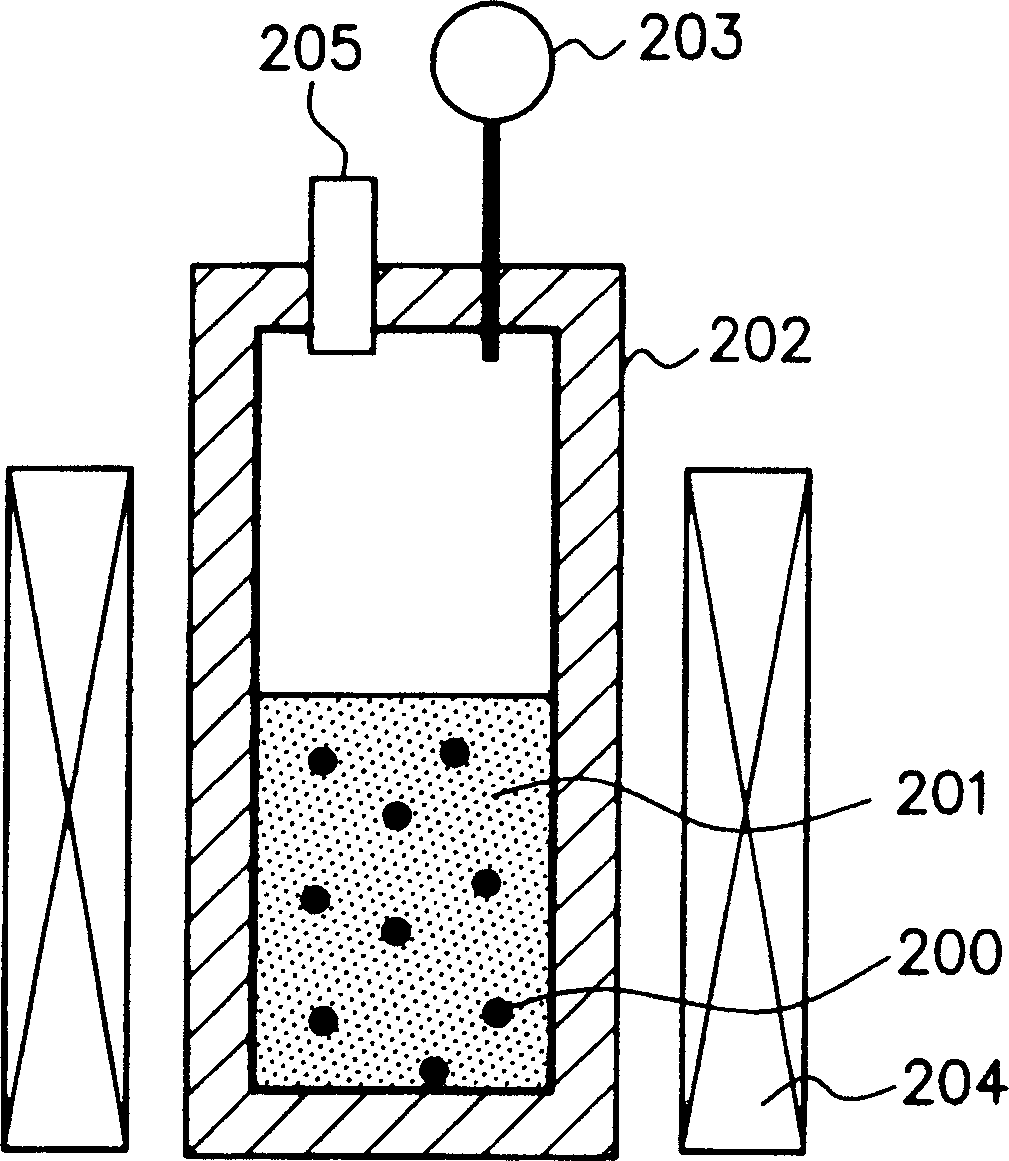

[0053] like figure 2 As shown, a pressure-resistant reaction vessel 202 equipped with a pressure gauge 203, a heater 204, and a safety valve 205 is used.

[0054] Add 2g of naphthalene (critical temperature 475°C, critical pressure 4.11MPa) as raw material 200, ferric chloride FeCl 3 0.2g, ethanol (critical temperature 243 ℃, critical pressure 6.38MPa) 2g as the solvent of ferric chloride, dry ice CO as the reaction medium forming substance 201 2 (Critical temperature 31° C., critical pressure 7.38 MPa) 80 g, and airtight, reacted at a temperature of 300° C. and a pressure of 12 MPa for 6 hours to obtain a reaction product. After extracting the obtained reaction product with toluene, use methanol / toluene=51 / 41 high-performance liquid chromatographic analysis when the toluene solution that the extracted reaction product is diluted to 200 times with toluene, in addition to unreacted naphthalene, with A peak was observed at the same retention time as previously measured with a...

Embodiment 2

[0056] In Example 1, 0.2 g of ferrocene was added to ferric chloride, and the same operation as in Example 1 was used to obtain a reaction product. Next, the obtained reaction product was dissolved in toluene and analyzed by the same high-performance liquid chromatography as in Example 1. As a result, in addition to unreacted toluene, a peak was observed at a retention time corresponding to the peak position of fullerene .

Embodiment 3

[0058] In Example 1, no ferric chloride catalyst was added, the reaction temperature was raised to 400° C., and the reaction product was obtained by the same operation as in Example 1. Next, the obtained reaction product was dissolved in toluene and analyzed by the same high performance liquid chromatography as in Example 1. As a result, in addition to unreacted naphthalene, a peak was observed at a retention time corresponding to the peak position of fullerene .

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com