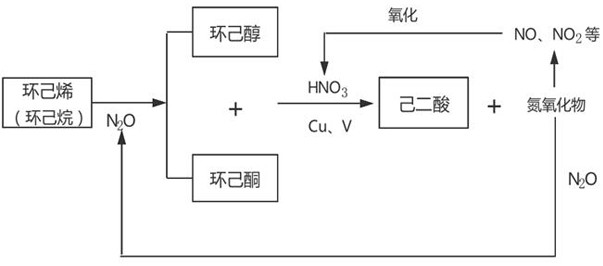

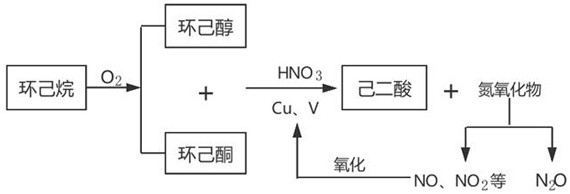

Production process for preparing cyclohexanone by oxidizing cyclohexene and laughing gas by using cobalt-based catalyst

A cobalt-based catalyst and production process technology, applied in the field of air pollution control, can solve the problems of low conversion rate of cyclohexanol and cyclohexanone, cumbersome oxidation process of cyclohexanol, difficult handling of laughing gas, etc., and achieve optimization of reaction products, good Application prospect, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The production technology that a kind of cobalt-based catalyst of present embodiment is used for cyclohexene and laughing gas oxidation to prepare cyclohexanone is as follows:

[0025] Catalysts are directly purchased or self-made.

[0026] Catalyst evaluation was carried out in a 100mL stainless steel batch reactor. Nitrogen gas was used to check the reactor for leaks before starting the reaction, and the test was carried out after the leak test was qualified.

[0027] Weigh 1.0g of cyclohexene as the reaction raw material and add it to the kettle reactor, add 20.0g of solvent N,N dimethylacetamide, and 0.1g of catalyst cobalt nitrate; after filling, close and seal the reactor, after sealing Replace the air in the kettle with nitrogen for 2-3 times, and then replace the nitrogen with nitrous oxide for 2-3 times; ensure that the reaction system is in the atmosphere of nitrous oxide, and introduce nitrous oxide to 1.0Mpa; The temperature of the system was programmed to ...

Embodiment 2

[0029] With embodiment 1, solvent does not have, and catalyst does not have, and other is with embodiment 1.

Embodiment 3

[0031] With embodiment 1, solvent benzyl alcohol, catalyzer cobalt acetate, other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com