Improved photoelectric module assembly parts

A technology of photoelectric modules and components, applied in optical components, electrical components, optics, etc., can solve the problems of occupation, inability to provide shielding electromagnetic interference, and multiple PCB spaces, so as to improve the overall capacity, enhance EMI shielding ability, and save PCB space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

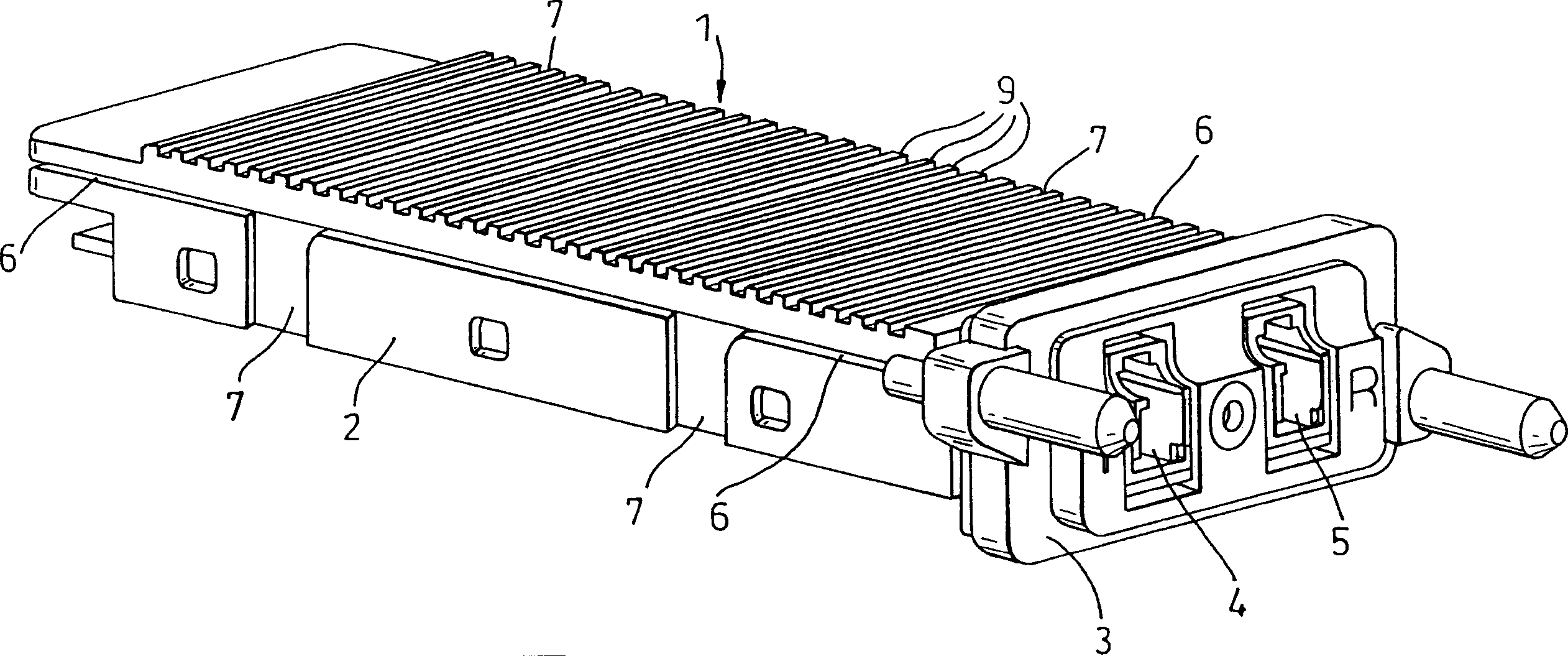

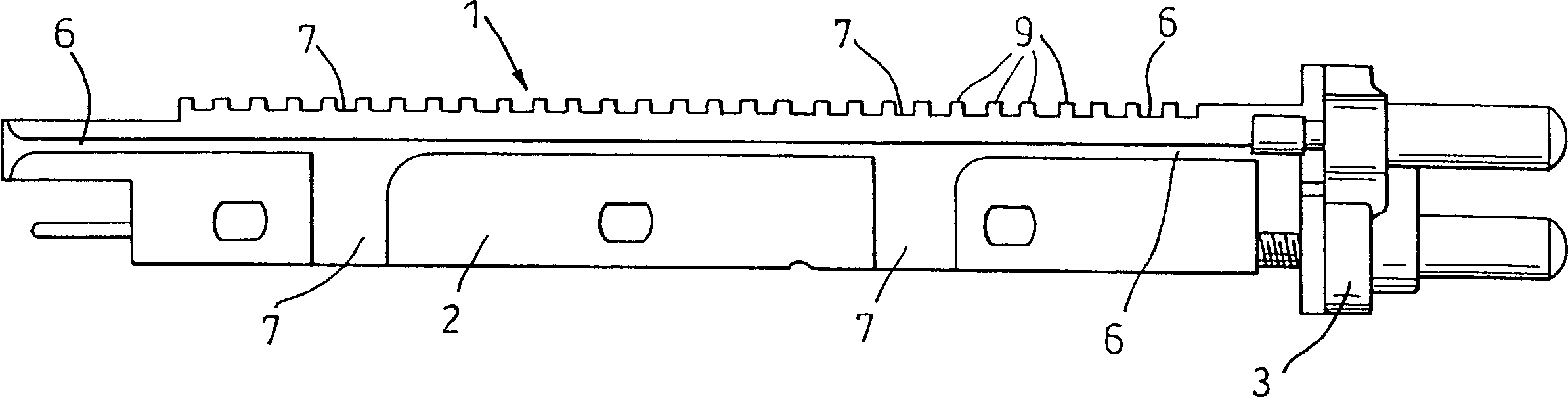

[0031] Such as Figure 2a versus 2b As shown, according to the present invention, the optoelectronic module 1 includes a housing 2, a front cover 3, and channels 4 and 5. The housing and the front cover are preferably made of metal materials. However, other suitable materials such as moderately filled and coated polymers can also be used. The casing is provided with a series of fins 9 arranged in rows to serve as heat sinks. Channels 4 and 5 provide access to the internal components of the module. In this embodiment, the channel 4 provides a way to connect to an optical signal transmitter (not shown in the figure) and the channel 5 provides a way to connect to an optical signal receiver (not shown in the figure). Alternatively, the channel 4 can provide a way to connect to the receiver and the channel 5 can provide a way to connect to the transmitter.

[0032] in Figure 2a versus 2b In the preferred embodiment shown, the holes 4 and 5 are of a type suitable for receiving optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com