Device and method for cleaning gluing nozzle

A technology for cleaning devices and nozzles, which is applied to spray devices, devices for coating liquid on surfaces, tobacco, etc., can solve the problems of cleaning and gluing nozzles, the structure of the cleaning device is large, and automatic cleaning is not completed, and achieves low wear and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

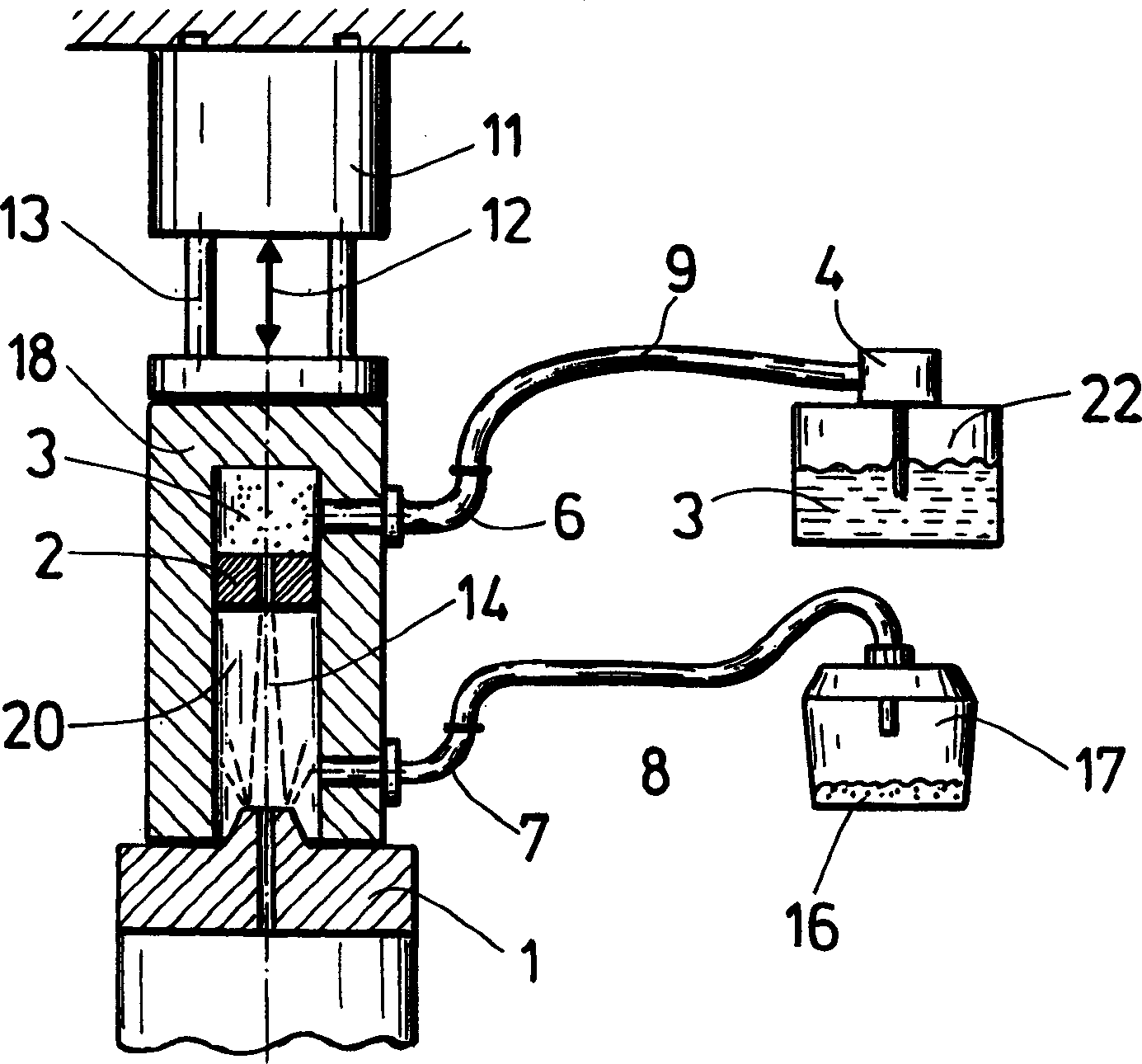

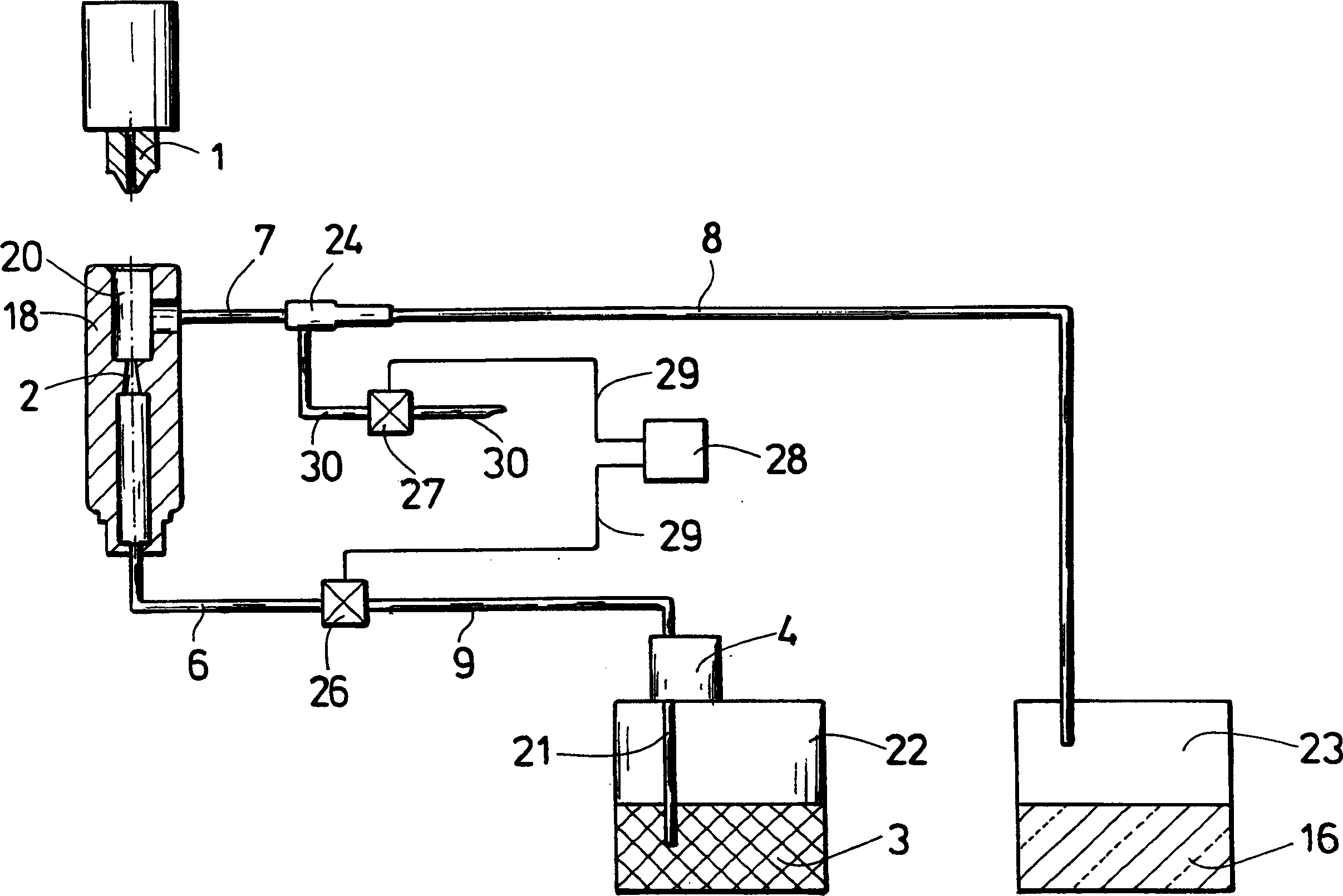

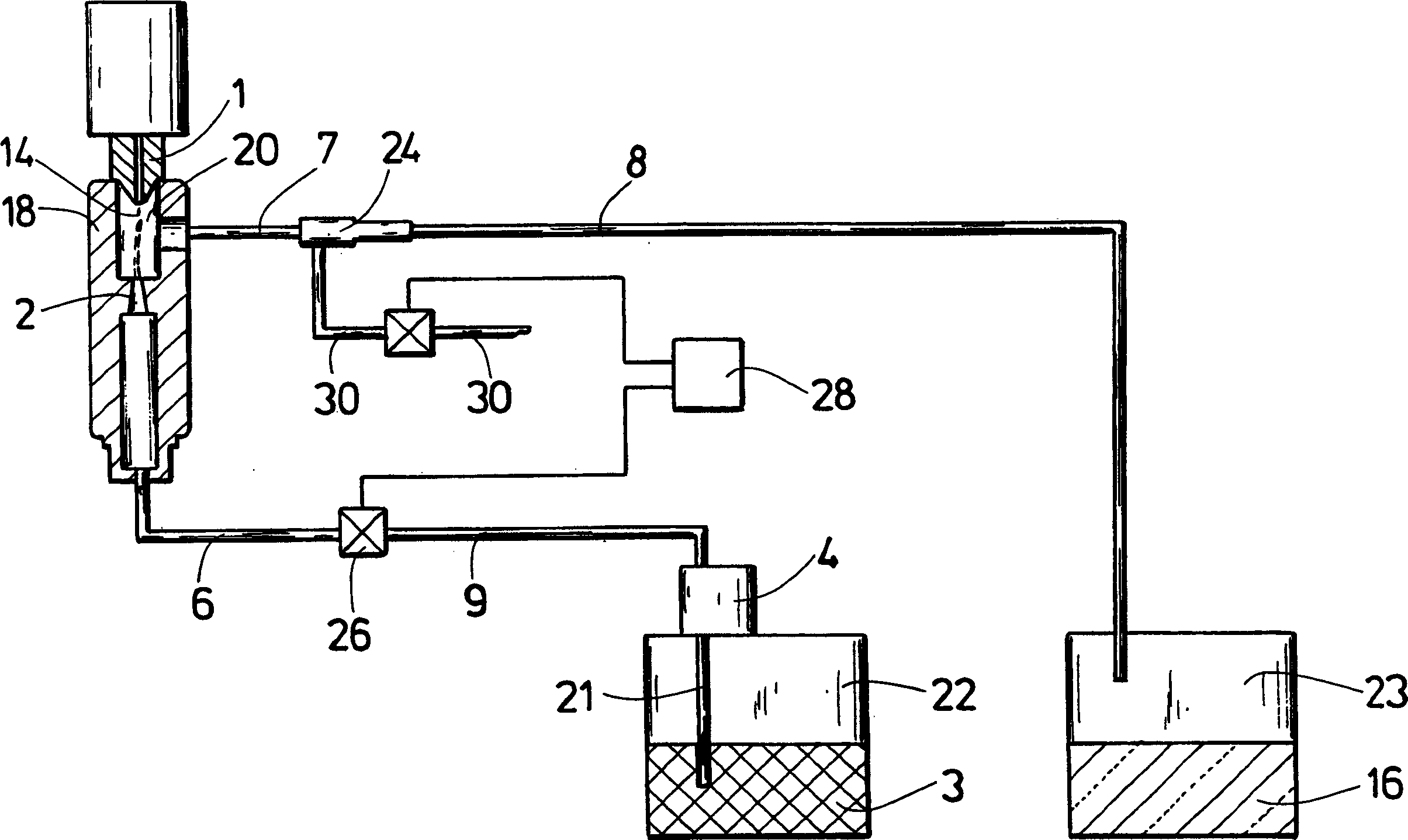

[0034] figure 1 A cleaning device of the present invention for cleaning one glue nozzle 1 is shown. In a housing 18, a cavity 20 is defined by a cleaning nozzle 2, the shell wall of the housing 18 and the glue nozzle 1. In the cavity 20, a water stream 14 is directly directed at the glue nozzle. In order to generate the water flow 14, the cleaning water 3 is pumped out from a water storage container 22 by a pump 4 and under pressure is sent to the housing 18 through a hose 9 and a pipe joint 6 and sent to the cleaning nozzle 2 . Since the pressure is quite high, the washing water is pressed through the nozzle and a water flow 14 is generated. The pump may be, for example, an AT20 type pump from Lamp-lintfort, Almatec, Germany.

[0035]A high-pressure water jet with a pressure of, for example, 4 bar to 8 bar, and preferably a pressure of 6 bar, is sprayed into the gumming nozzle 1. In this embodiment, the gumming nozzle is arranged under the cleaning device and the water flow kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com