New method for preparing natural benzaldehyde by hydrolyzing bay leaves oil

A technology of laurel leaf oil and benzaldehyde, which is applied to the preparation of carbonyl compounds by hydrolysis, organic chemistry, etc., can solve the problems of low yield, achieve high yield, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

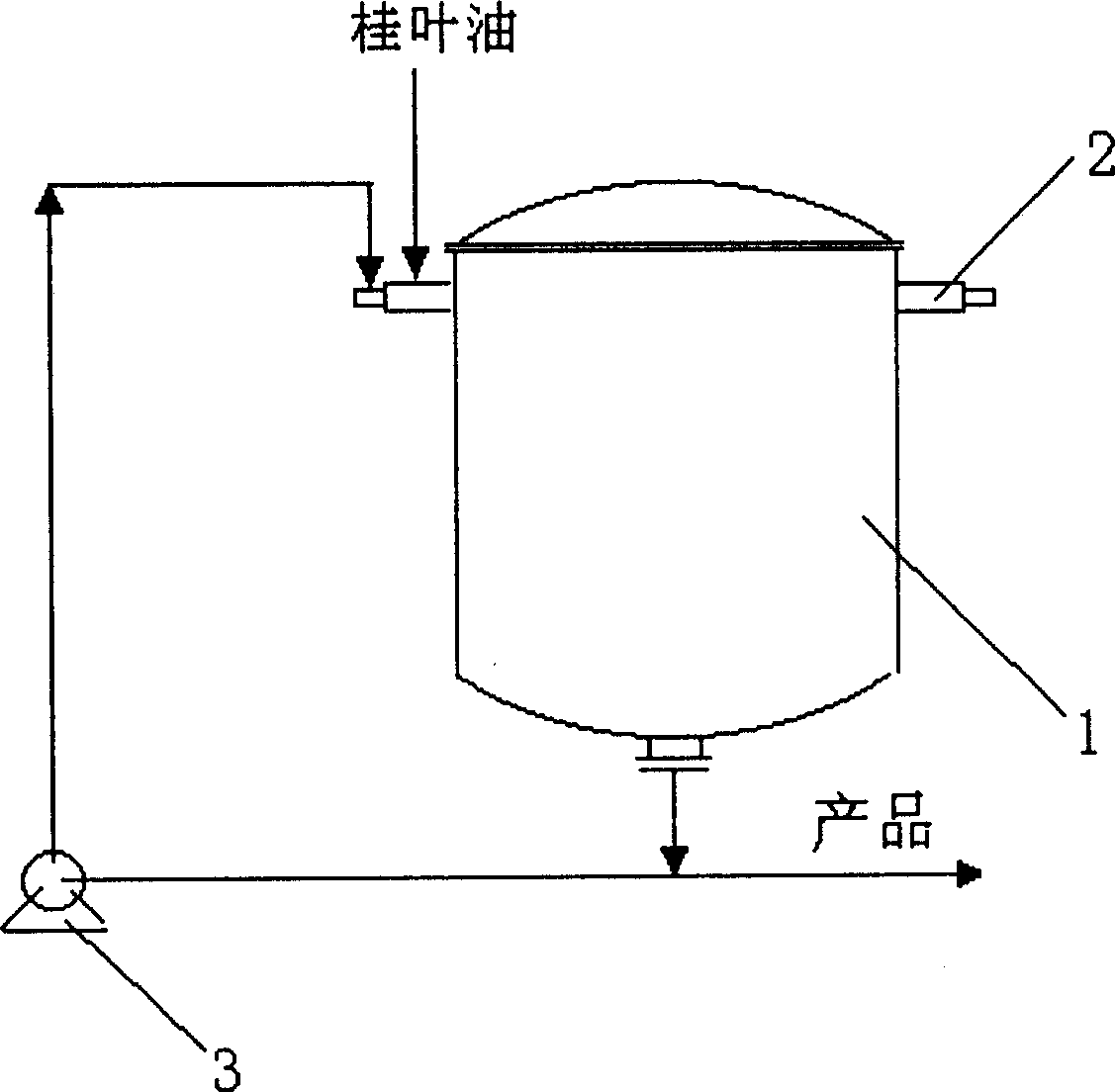

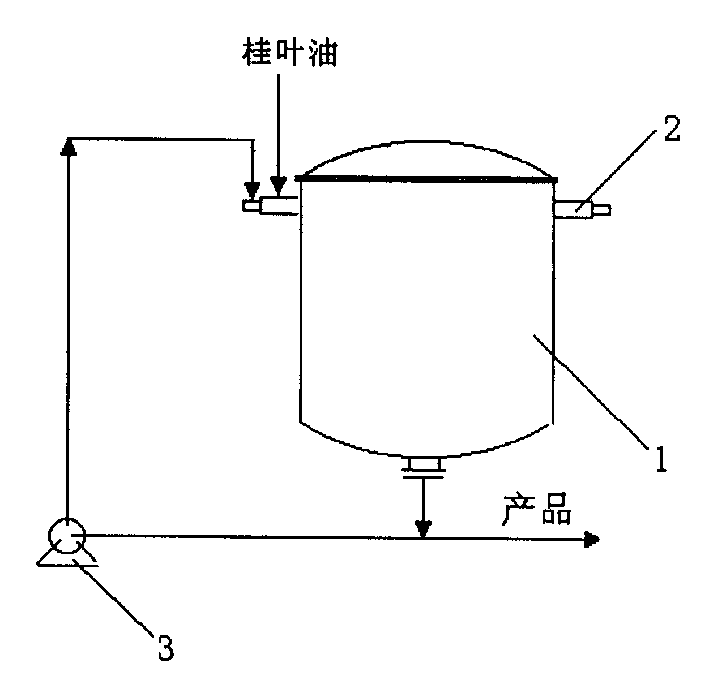

[0015] use figure 1 process shown. Cinnamon leaf oil and NaOH aqueous solution are sprayed into reactor 1 after being sprayed into reactor 1 by the two-channel nozzle 2 that is arranged on the top of reactor 1 respectively, make cinnamon leaf oil and alkaline substance react under atomized state, generate benzaldehyde, react The material at the bottom of the device 1 is sent to the nozzle 2 at the top by the circulation pump 3, and is recycled until the reaction is finished, and then adopts a conventional method to collect benzaldehyde from the reaction product.

[0016] The linear velocity of bay leaf oil at the outlet of nozzle 2 is 15 m / s, and the linear velocity of NaOH aqueous solution at the outlet of nozzle 2 is 50~300 m / s. The NaOH consumption is 0.02% of the bay leaf oil weight.

[0017] The preferred reaction temperature is 100-110°C, and the reaction time is 0.5-1.5 hours. The yield is 45.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com