Positive encapsulating management tool with pair of optical collimators and encapsulation method using the tool

A packaging method and collimator technology, applied in the coupling of optical waveguides, etc., can solve the problems of failure to provide operator adjustment functions, loss of accuracy, and incorrect accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

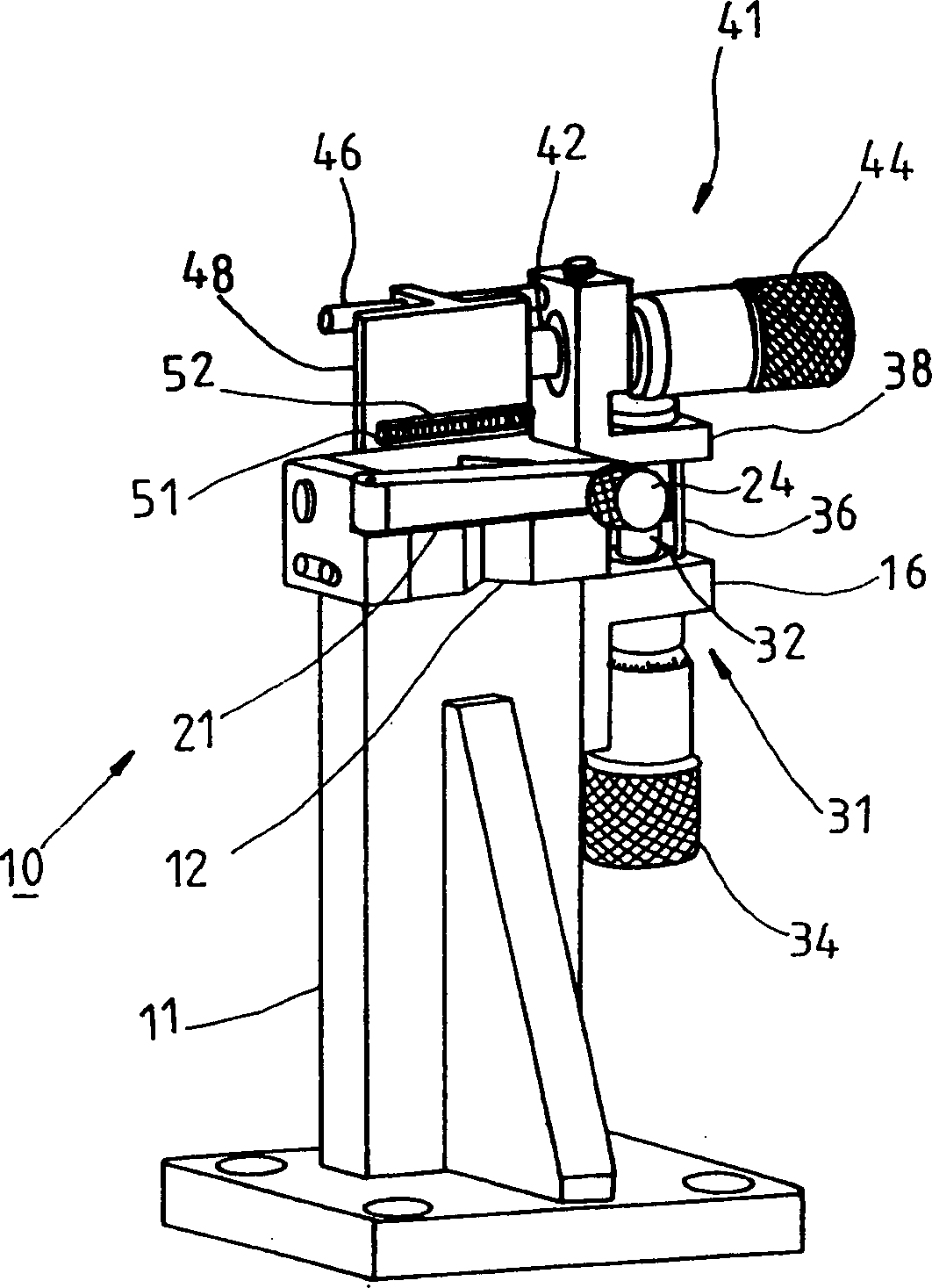

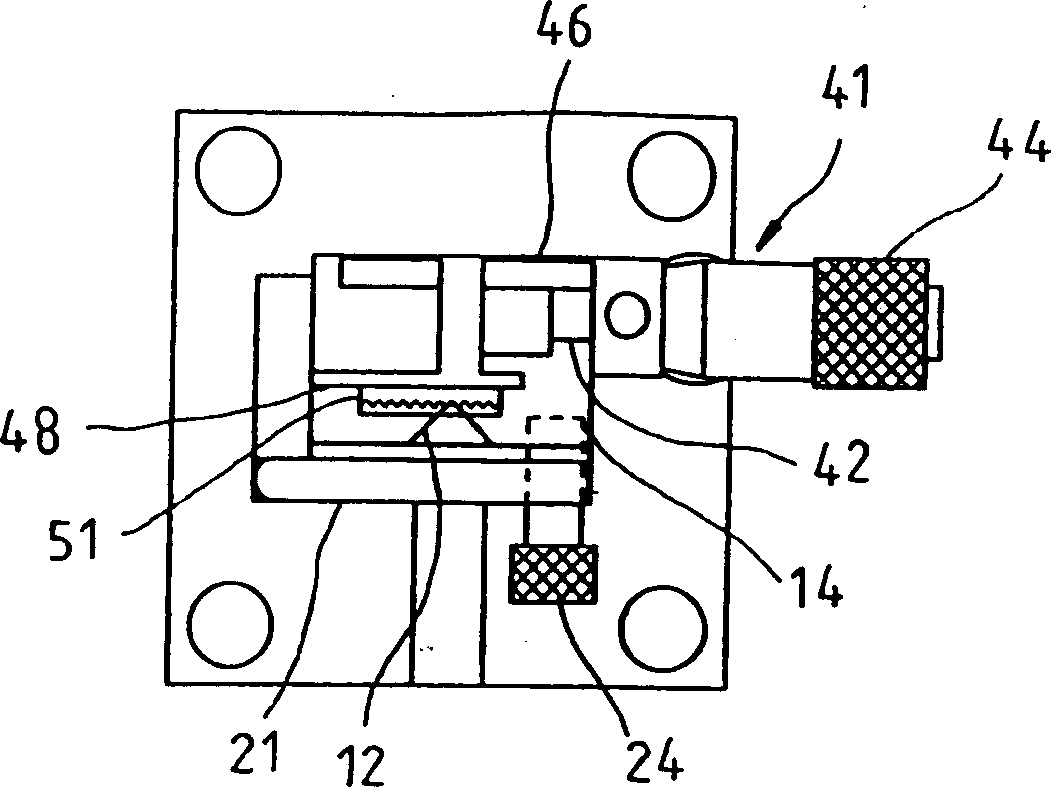

[0038] see Figure 2 to Figure 4 , an optical collimator alignment package jig 10 provided by a preferred embodiment of the present invention is mainly composed of a frame body 11, a clamping member 21, a Z-axis moving platform 31, and an X-axis moving platform 41 , and a set of moving parts 51, wherein:

[0039] The frame body 11 has a groove 12 at a predetermined position. One side is provided with a fixed table 16;

[0040] The clamping member 21 is a rod body, one end is set on the frame body 11 and can be opened and closed corresponding to the groove 12, and the other end is pierced with a bolt 24, when the rod body is attached to the frame body 11 , the bolt 24 can be screwed into the screw hole 14, so as to fix the clamped object;

[0041] The Z-axis moving platform 31 is composed of a screw rod 32, a knob 34 sleeved at the control end of the screw rod 32, a certain guide rod 36, and a connecting platform 38 arranged at the free end of the screw rod 32; the screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com