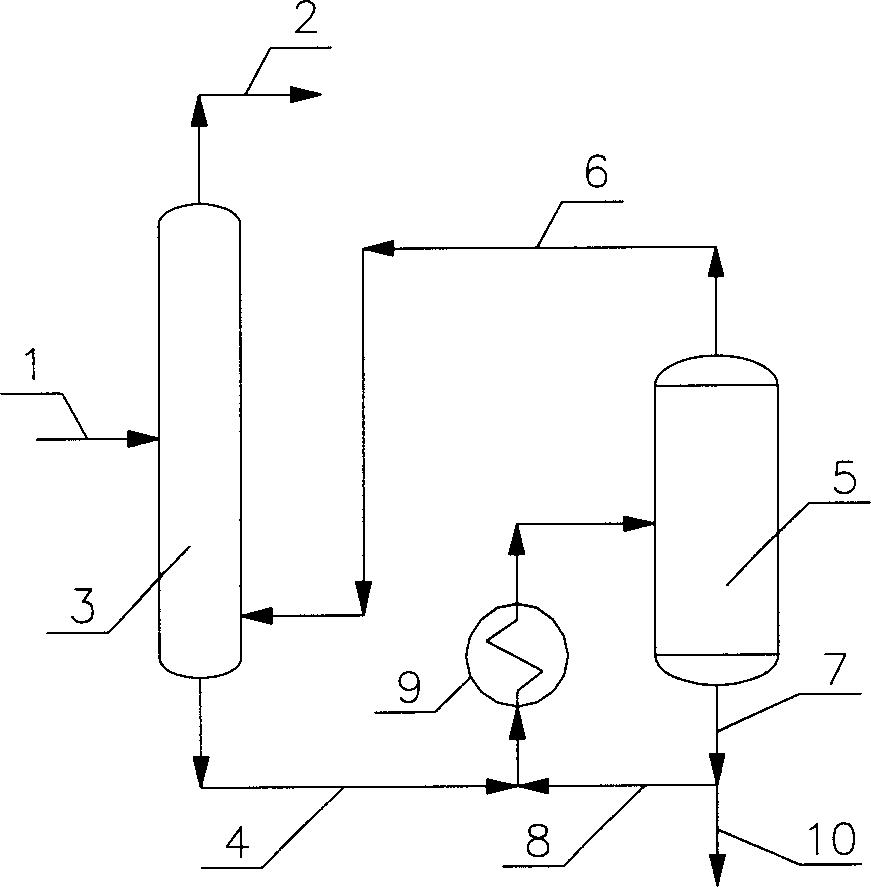

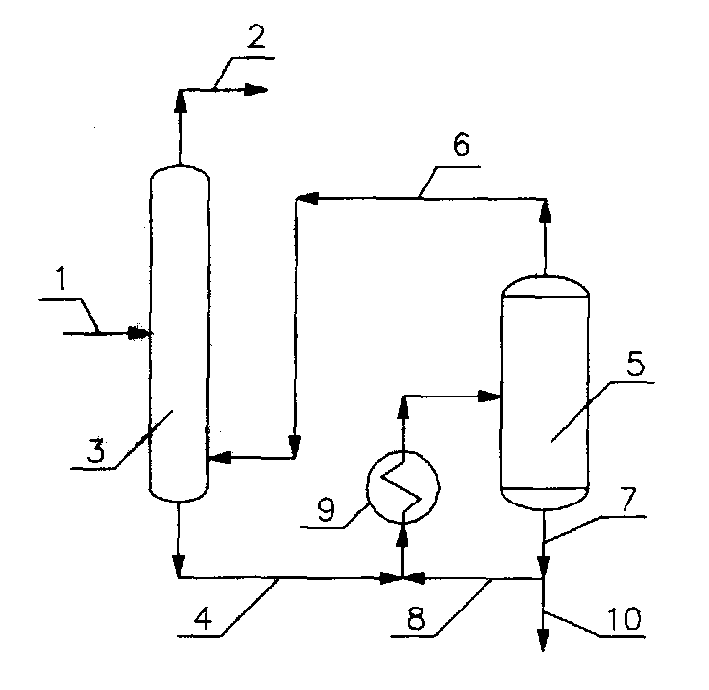

Adiabatic flash method for styrene tar oil

An adiabatic flash evaporation, styrene technology, applied in chemical instruments and methods, organic chemistry, hydrocarbon purification/separation, etc., can solve the problems of large loss of styrene, poor evaporation effect, high equipment investment, and achieve flash evaporation energy. The effect of improving, increasing liquidity, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0020] According to the conditions and steps of embodiment 1, just changing the operating temperature of the flash tank is 120 ℃, and the operating pressure is 30KPa, and the amount of tar in the middle part of the flash tank is circulated by weight ratio: the tar amount discharged is 140: 1, then out The weight percent concentration of styrene in the material tar is 4.98%. [Example 3]

Embodiment 3

[0021] According to the conditions and steps of embodiment 1, just changing the operating temperature of the flash tank is 140 ℃, and the operating pressure is 15KPa, and the amount of tar in the middle part of the flash tank is circulated by weight ratio: the tar amount discharged is 130: 1, then the output The weight percent concentration of styrene in the material tar is 3.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com