Process for preparing surface bonded TiO2/SiO2 photocatalyst

A photocatalyst and bonding technology, which is applied in the field of preparation of surface-bonded TiO2/SiO2 photocatalyst, can solve the problems of easy detachment of titanium oxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical characteristics and advantages of the present invention can be seen through the embodiments and application examples given below.

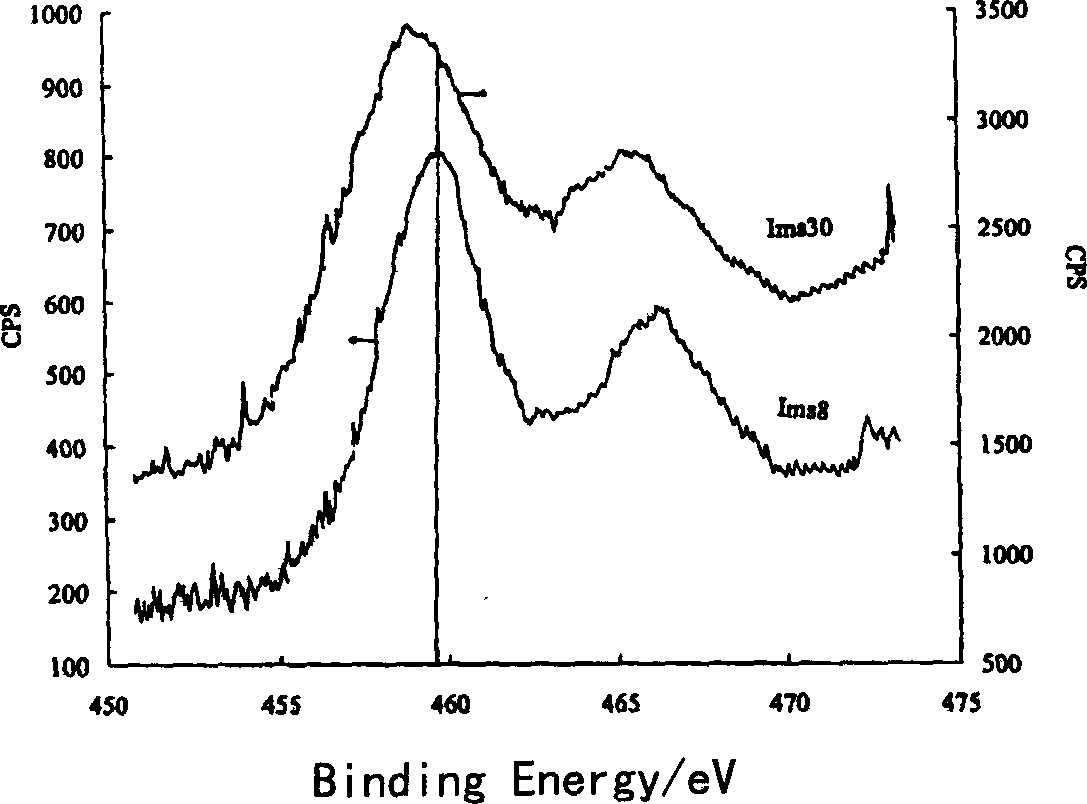

[0009] 1. Surface-bonded TiO 2 / SiO 2 Structural characterization of photocatalysts

[0010] The volume ratio of tetrabutyl titanate to cyclohexane is 1:3. The dry porous silica gel is impregnated in the cyclohexane solution of tetrabutyl titanate to react for 15 hours, and then the cyclohexane is evaporated at 40°C. The sample After drying at 100°C, it was calcined in air at 400°C for 5 hours, at which point tetrabutyl titanate was oxidized to TiO 2 , cooled, loaded on the surface of porous silica gel through Ti-O-Si bonds, and obtained surface-bonded TiO 2 / SiO 2 catalyst of light. Because TiO 2 Loading on the surface of porous silica gel is a well-known technology, and this embodiment will not describe it in detail here.

[0011] TiO prepared above 2 / SiO 2 Catalyst, the results of XRD characterization show that te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com