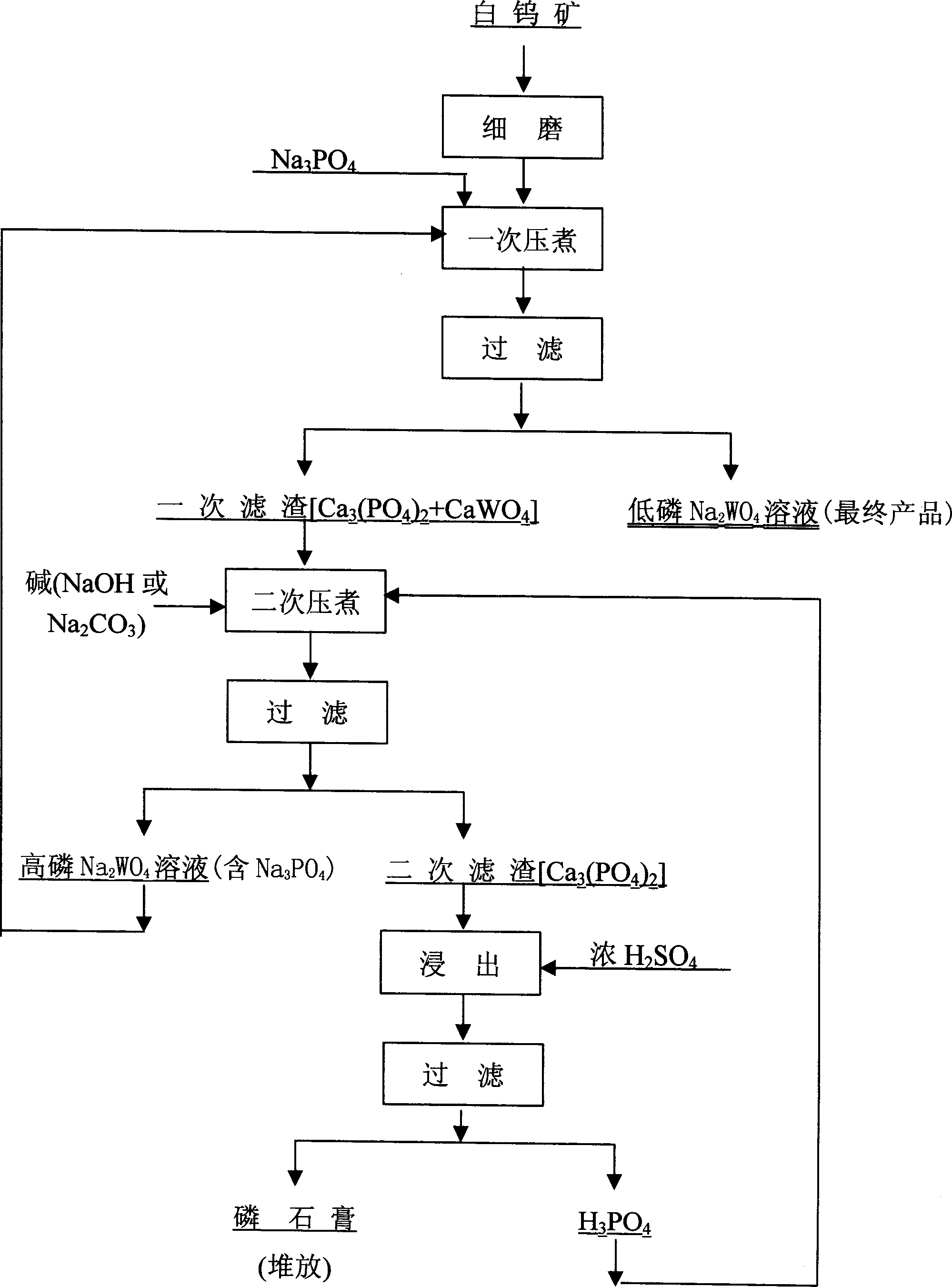

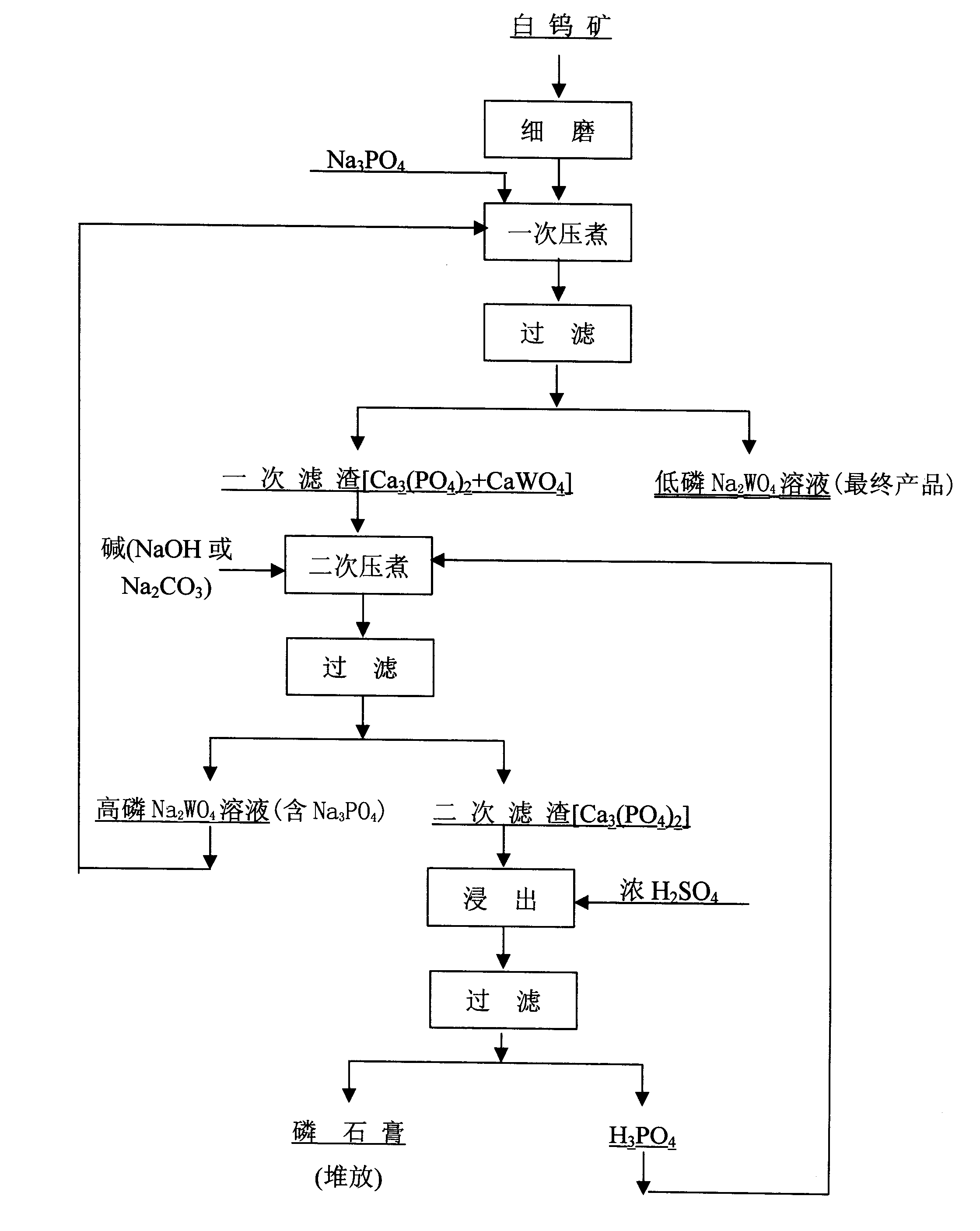

Scheelite decomposing process

A technology of scheelite and phosphoric acid, applied in the field of decomposing scheelite, can solve the problem of high alkalinity, achieve the effect of high decomposition rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] 1000g containing 67% WO 3 scheelite, ground to -0.045mm>91%, add phosphorus 3g / L NaWO 4 Add the solution to an ordinary stirring autoclave, and keep it warm for 1 hour at a pressure of 0.5MPa and a temperature of 160°C. Na 2 WO 4 The phosphorus content in the solution is reduced to 0.15g / L, and the scheelite (filter residue) after the first pressure cooking contains WO 3 58%, add 1.2 times the theoretical amount of phosphoric acid (calculated according to the Ca content in scheelite), and then add 1.3 times the theoretical amount of NaOH (according to the WO in scheelite) 4 content calculation), at a pressure of 0.8MPa and a temperature of 180°C, the second pressure cooking was carried out, and the heat preservation was carried out for 1 hour. The secondary filter residue contained WO 3 It is 0.7%, that is, the decomposition rate is 99.5%.

example 2

[0022] The pressure of the first pressure cooking is 0.1MPa, the temperature is 120°C, and the holding time is 0.5 hours; the second pressure cooking is to add 1.1 times the theoretical amount of phosphoric acid and 1.4 times the theoretical amount of NaOH, the pressure is 0.5MPa, and the temperature is 160 ℃, all the other are the same as Example 1.

example 3

[0024] The pressure of the first pressure cooking is 0.2MPa, the temperature is 130°C, and the holding time is 0.5 hours; the second pressure cooking is 1.15 times the theoretical amount of phosphoric acid, plus 1.2 times the theoretical amount of NaOH, the pressure is 0.6MPa, and the temperature is 160 ℃, all the other are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com