Oxygen sensor

An oxygen sensor, zirconia technology, applied in the field of oxygen sensors, can solve problems such as low gas response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0083] Detailed description of the invention (Experiment 1)

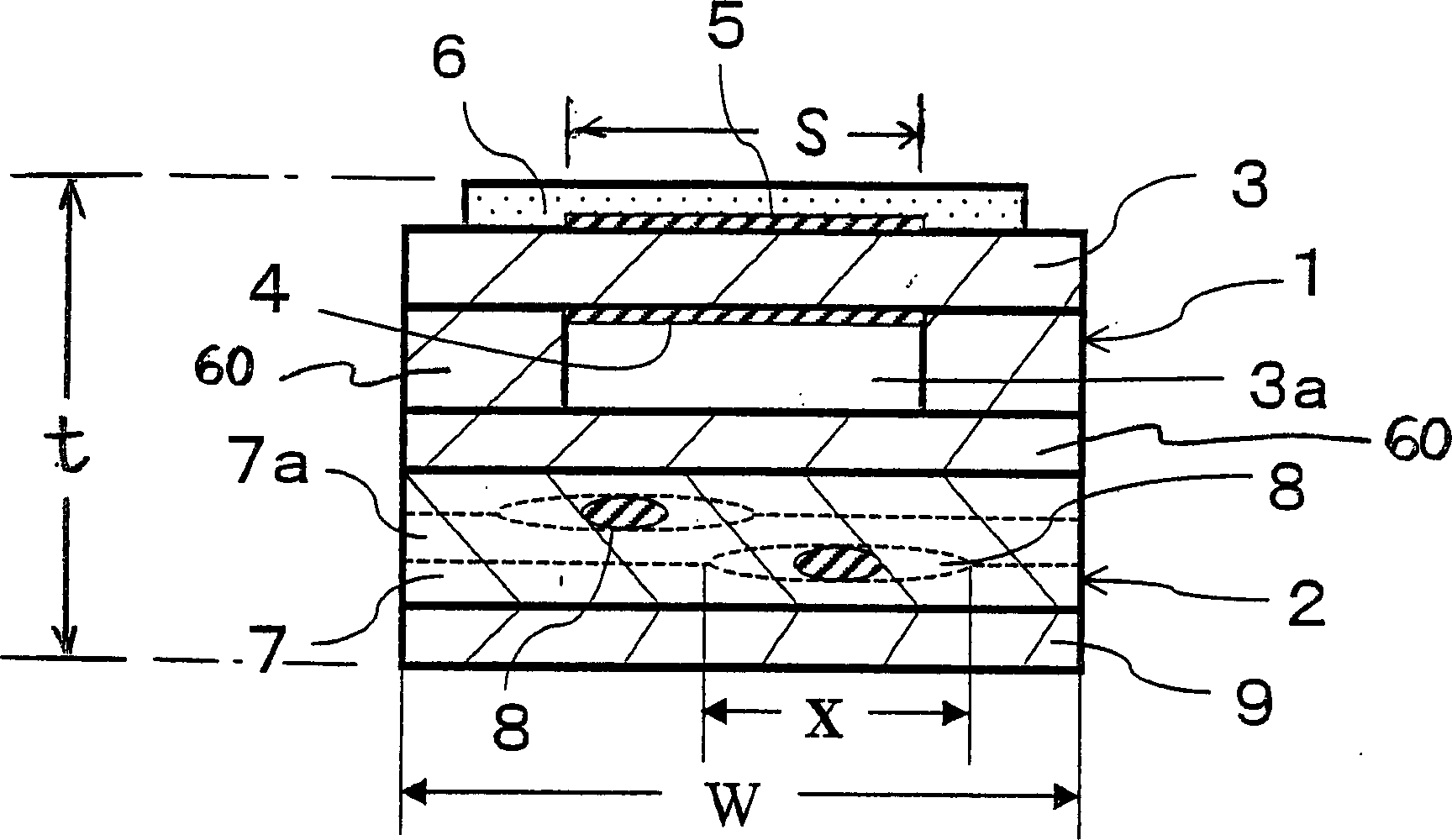

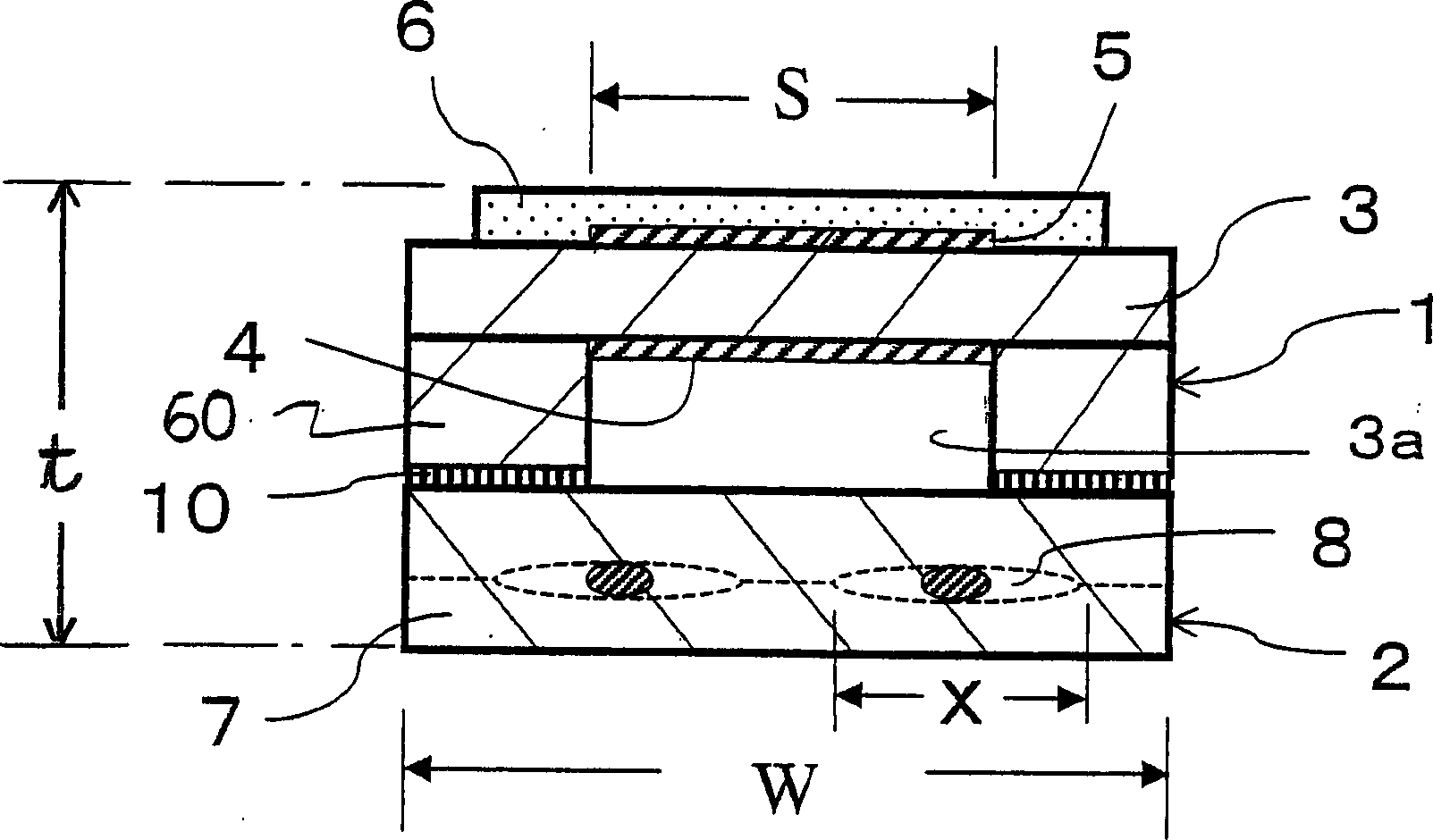

[0084] like figure 1 The lambda sensor shown is based on the following Figure 7 method to make.

[0085] First, an alumina powder with a purity of 99.9% containing 5 mol% of Y was prepared 2 O 3 Zirconia powder (containing 0.1% by weight of Si), platinum powder ① (average particle diameter: 0.1 μm) containing zirconia (containing 8% moL of yttrium oxide) by volume 30%, alumina powder containing 20% by volume The platinum powder ②.

[0086] First, the polyvinyl alcohol solution is added to the above-mentioned zirconia powder to prepare a slurry, which is then extruded to form a zirconia green sheet 13, the thickness of which is 0.4 mm after sintering.

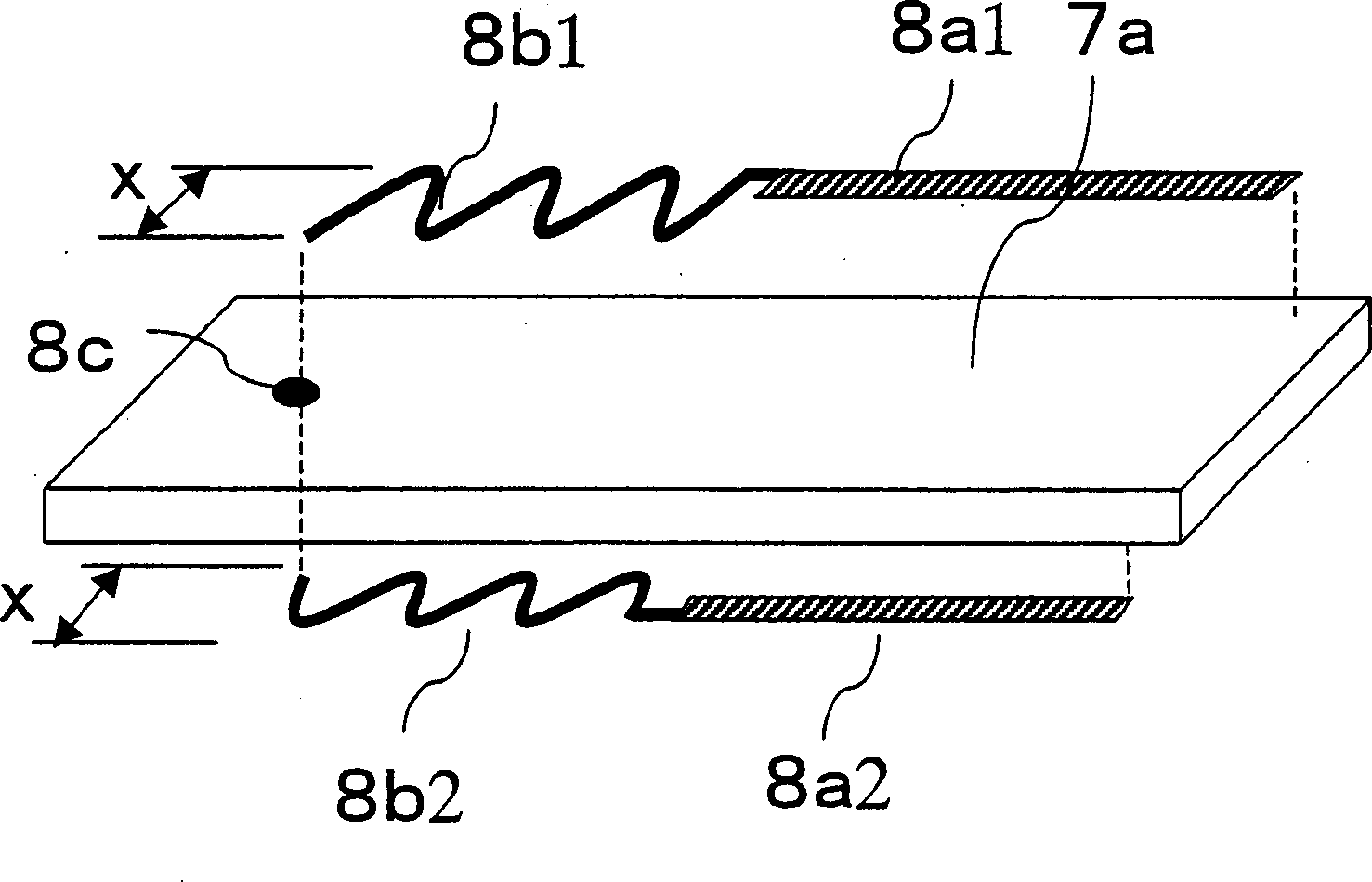

[0087] Then, the conductive paste containing platinum powder ① is printed on both surfaces of the green sheet 13 by screen printing, thereby forming electrode patterns 14, wire patterns 15 and electrode sheet patterns 16 serving as measuring electrodes and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com