In-situ boiler combustion optimizing control system based on computational intelligence

A technology for optimal control and boiler combustion, which is applied in general control systems, control/regulation systems, and adaptive control, etc. It can solve the difficulty of building a boiler combustion characteristic model for boiler combustion, the increase of carbon content in fly ash, and the inability to optimize boiler combustion. control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

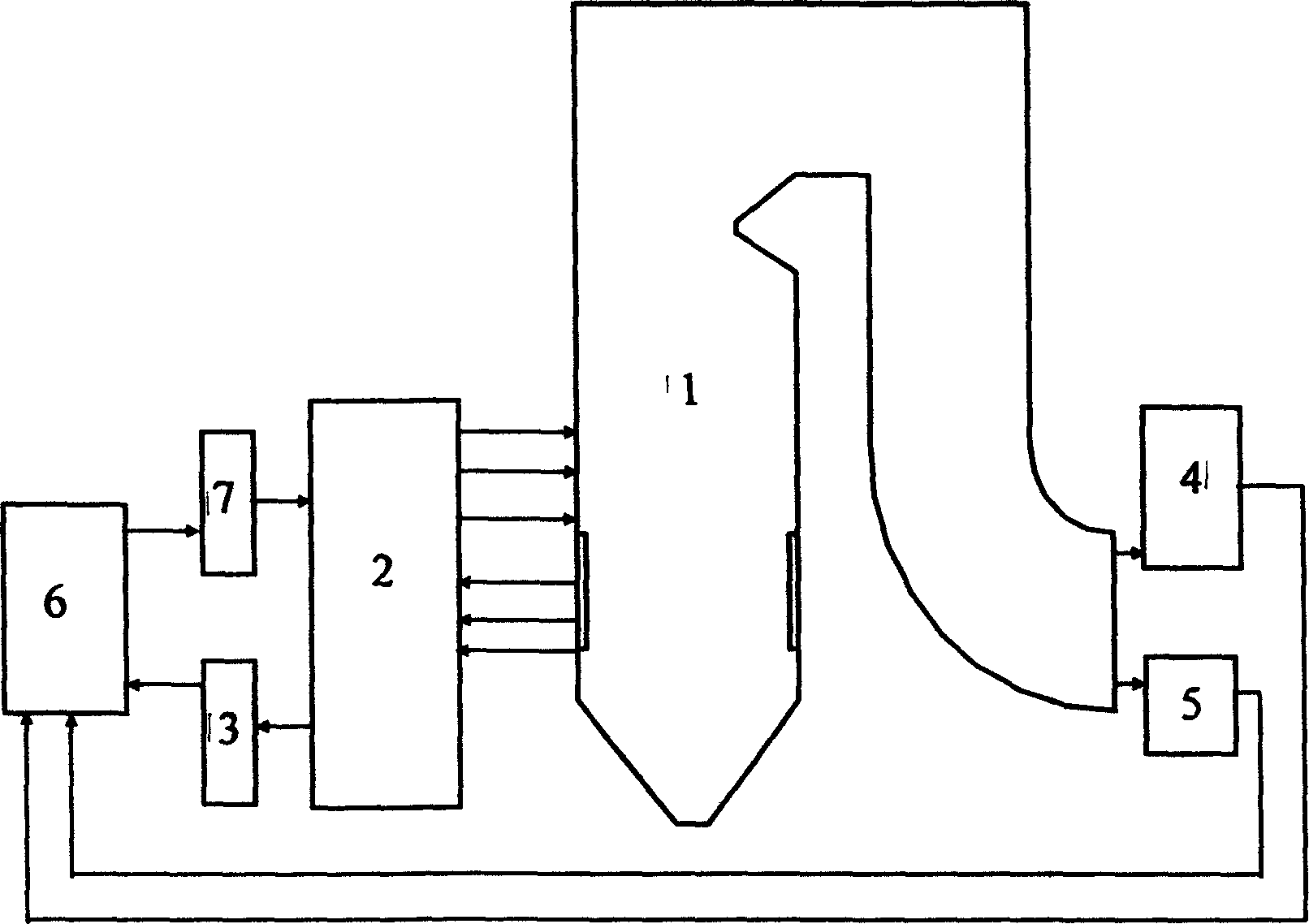

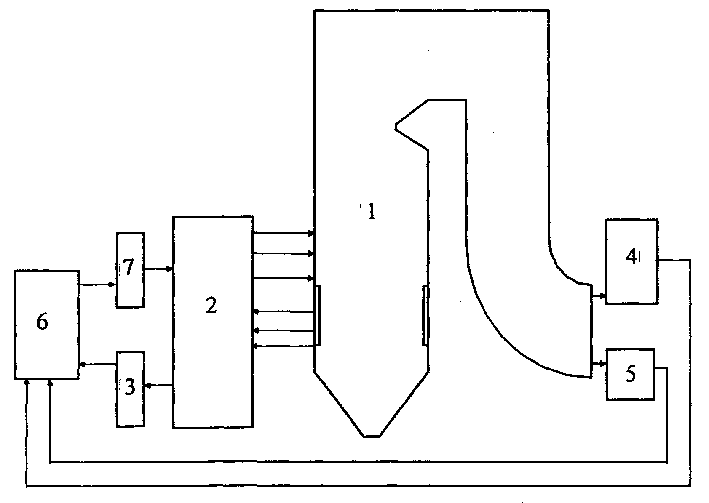

[0009] The boiler combustion online optimization control system based on computational intelligence downloads the operating parameters of the boiler from the distributed control system 2 through the download interface 3 of the boiler 1 distributed control system 2, and obtains the boiler smoke exhaust group from the boiler tail flue gas component online monitoring system 4 and obtain the carbon content of the boiler fly ash from the fly ash carbon content monitor 5 installed at the tail of the boiler, the boiler operating parameters, the components of the exhaust smoke and the data of the carbon content of the fly ash are stored in the combustion online optimization control system Learning is carried out in the database of the central processing computer 6 and nonlinear models and global optimization calculations are established.

[0010] The invention utilizes the data download interface of the distributed control system (DCS) of the power station boiler to download the releva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com