Critical field force inducing operation controller

A technology of controller and potentiometer, which is applied in the direction of adaptive control, mechanical pressure/force control, general control system, etc., can solve problems such as failure to meet requirements, and achieve the effect of less debugging work, light weight and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with each figure:

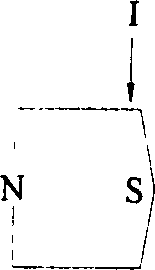

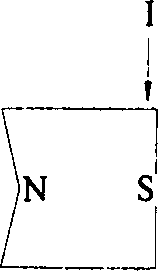

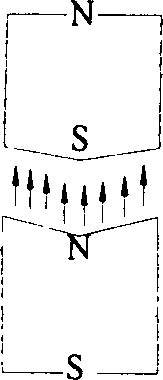

[0037] The present invention is made up of following main parts, and the frame mechanism f (1) of this device is installed on the swing lever L (2) of the front end of the upper wall of the frame mechanism in the form of a movable shaft. This swing lever can be as Figure 9Swing in the direction shown, the range of motion is not less than 40 degrees. There is a finger collar O (3) at the lower end of this swing bar, which is used for operator's finger operation. A rectangular coil frame K0 (4) with a cylindrical surface shape is fixedly installed in the central part of the swing rod, and enameled wire is wound on the coil frame to form a moving coil L0 (5), which moves together with the swing rod. On the left side of the swing rod, two magnetic poles M1 (6) and M2 (7) are installed according to a certain inclination, wherein M1 is located at the top and M2 is located at the bottom; co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com