Combine-harvester

A technology for combine harvesters and harvesters, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of easy subsidence of rice fields, inability to return straw to the field, and high stubble after cutting first, so as to achieve relief. And the effect of eliminating the global warming effect, excellent environmental protection function, and simplifying the transportation part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

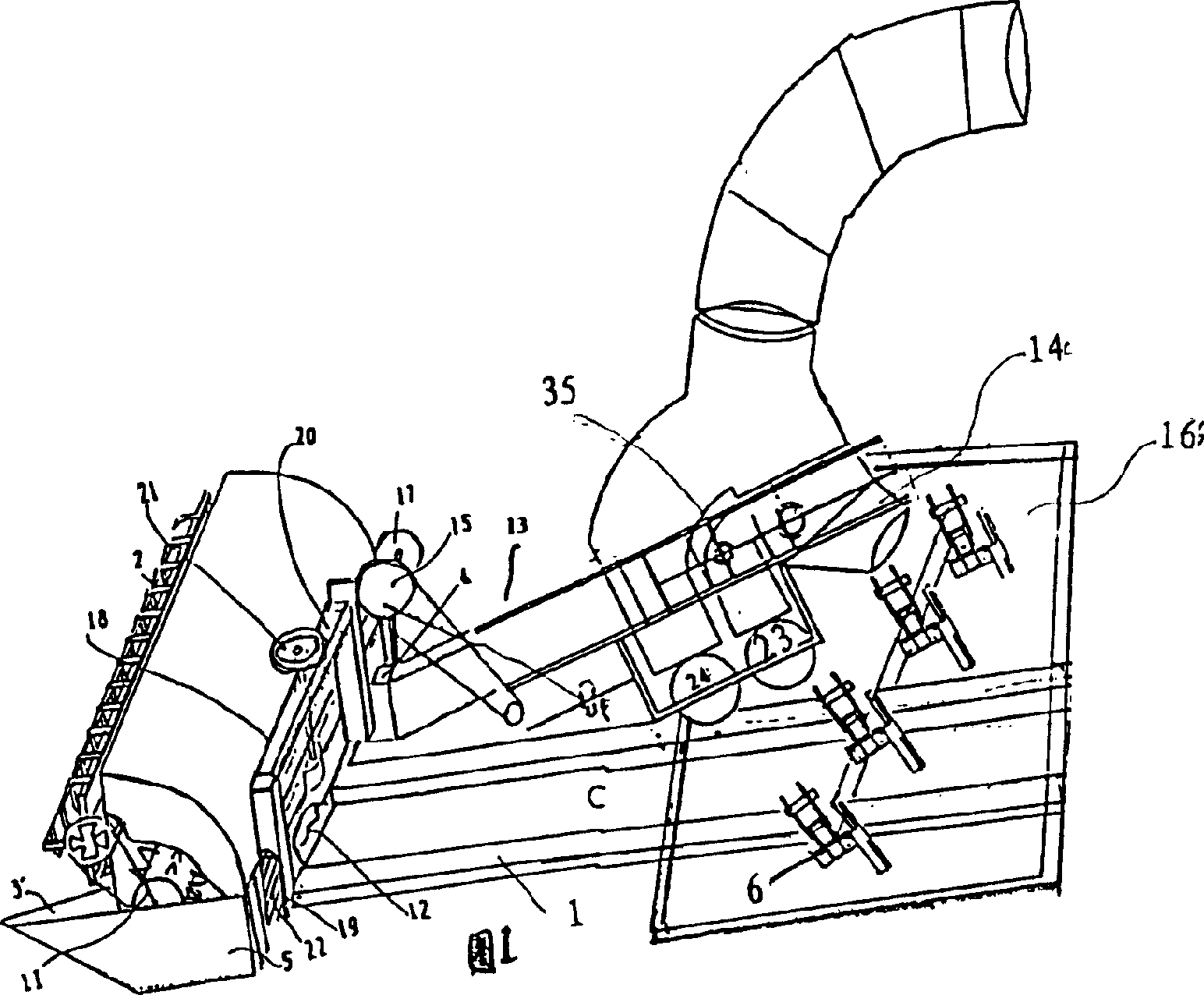

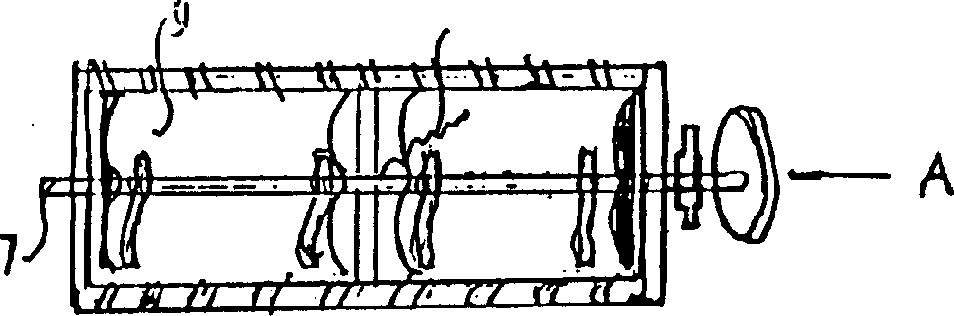

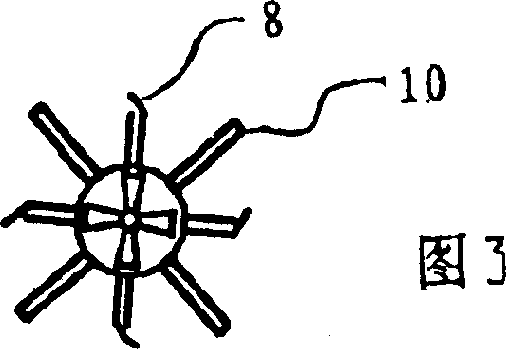

[0025] Referring to Fig. 1~Fig. 5, on the frame 1 there are hollow frame 2 for ear inlet, threshing work chamber 5 containing ear inlet 3 and grain outlet 4, and cutter 6 successively on the frame 1. Advance the ear comb teeth 8 that many rows are housed on the fixed shaft 7 in the fringe hollow frame. Cooperate with the threshing working chamber and can realize the baffle sieve plate 9 of gold sealing and the kneading elastic pressing piece 10 that advances ear tooth and be contained in a pair. A drum 11 and a screw pusher 12 are installed in the threshing work chamber, and a conveying trough 13 containing a scraper is installed at the grain outlet, the grain receiving hopper 14 is hung on the conveying trough, the grain throwing fan 23, the selection fan 24, the conveying trough Groove residual fringe is handled 35, clutch is housed on the output belt pulley 15 on the tractor. The transmission mechanism 17 transmits power to the roller and the screw conveyor. Elevating adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com