High-capacity controllable reactor

A reactor, large-capacity technology, used in electrical components, circuit devices, emergency protection circuit devices, etc., can solve the problem of large secondary side current, and achieve the effect of stable response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

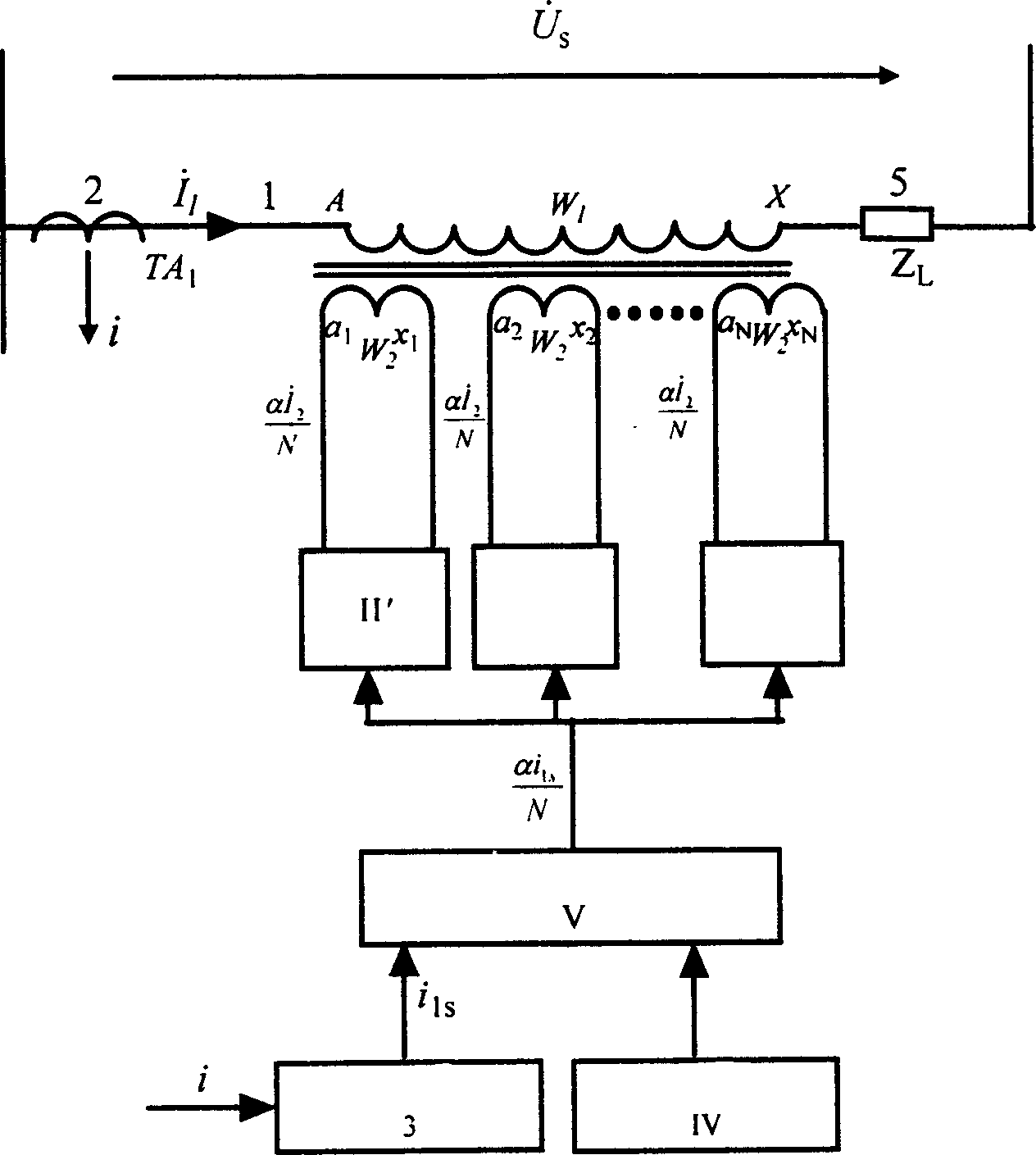

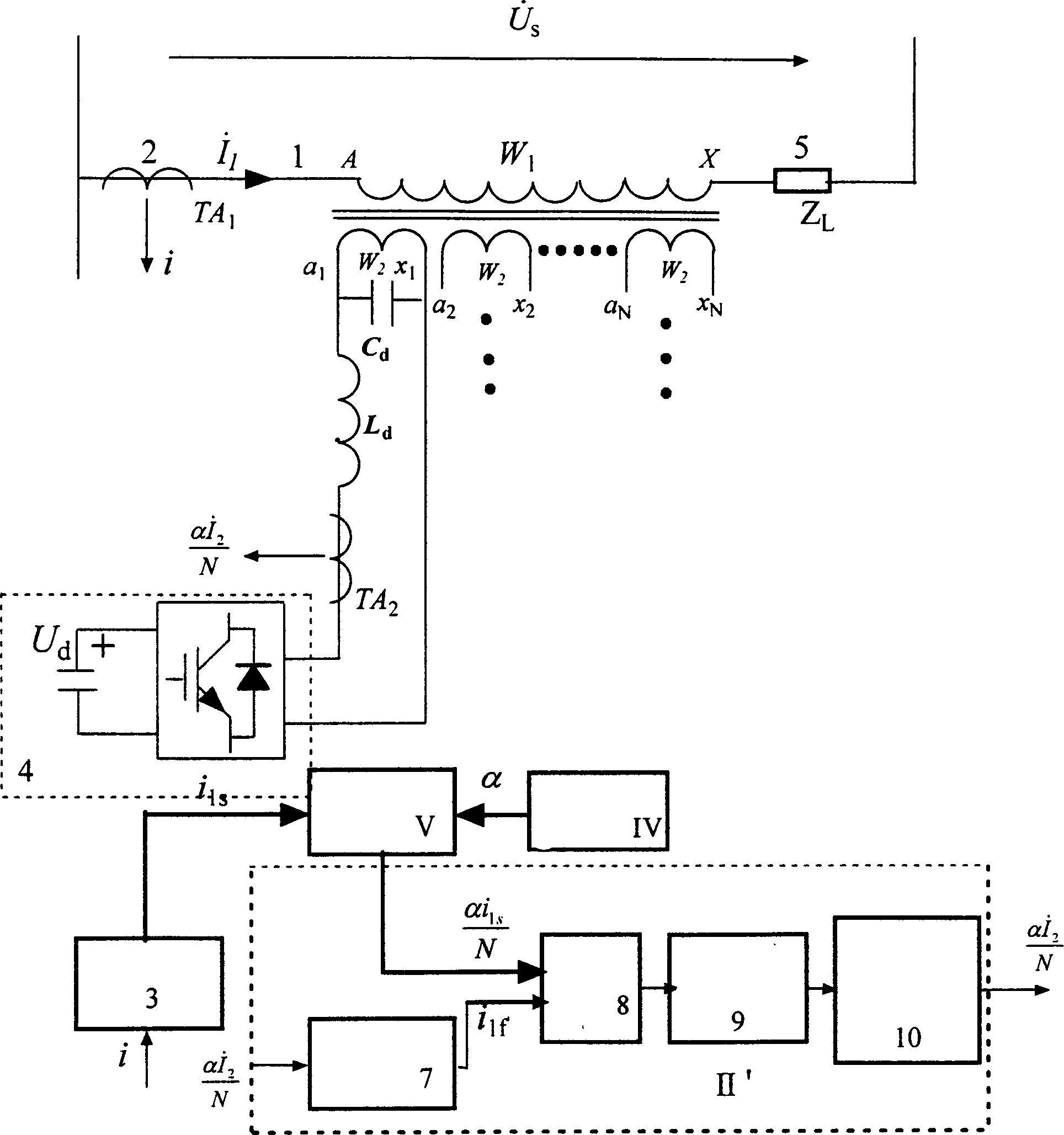

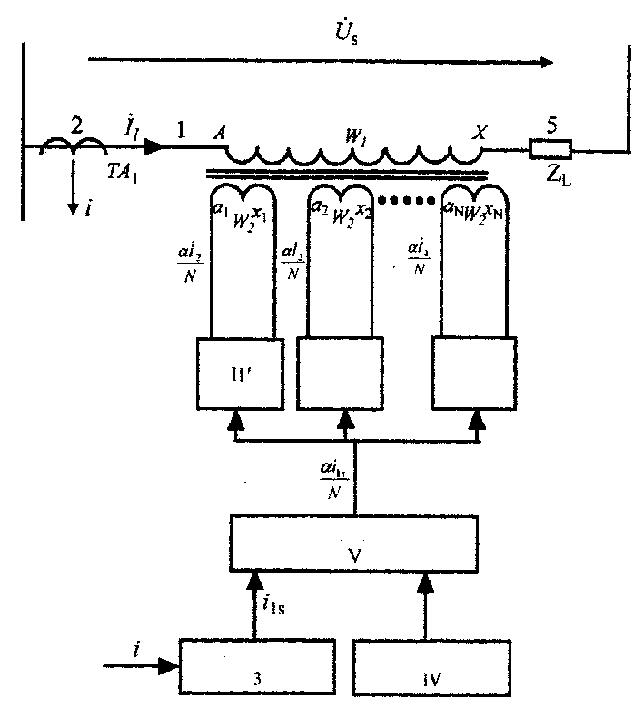

[0020] Such as figure 1 As shown, the controllable reactor in the present invention is mainly composed of five units: current detection unit I, compensation current generation unit II, transformer III, main control unit IV, and current signal setting unit V. The current detection unit 1 includes a current transformer 2 located on the primary grid bus 1 of the transformer, and a current detection link 3 connected to the output end of the current transformer 2 . The compensation current generating unit II is composed of N (N≤500) identical compensation current generating subunits II'. Transformer III, the secondary side of which is provided with N windings, each of which has W turns 2 , with the same geometric dimensions.

[0021] The working principle of the above controllable reactor is:

[0022] (1) The current sensor 2 sends the current (i) waveform of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com