Oxygen transport membrane for silicon oxide plant

A technology of silicon dioxide and silicon oxidation, which is applied in the preparation of silicon oxide, silicon dioxide and oxygen to achieve the effect of promoting effective purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

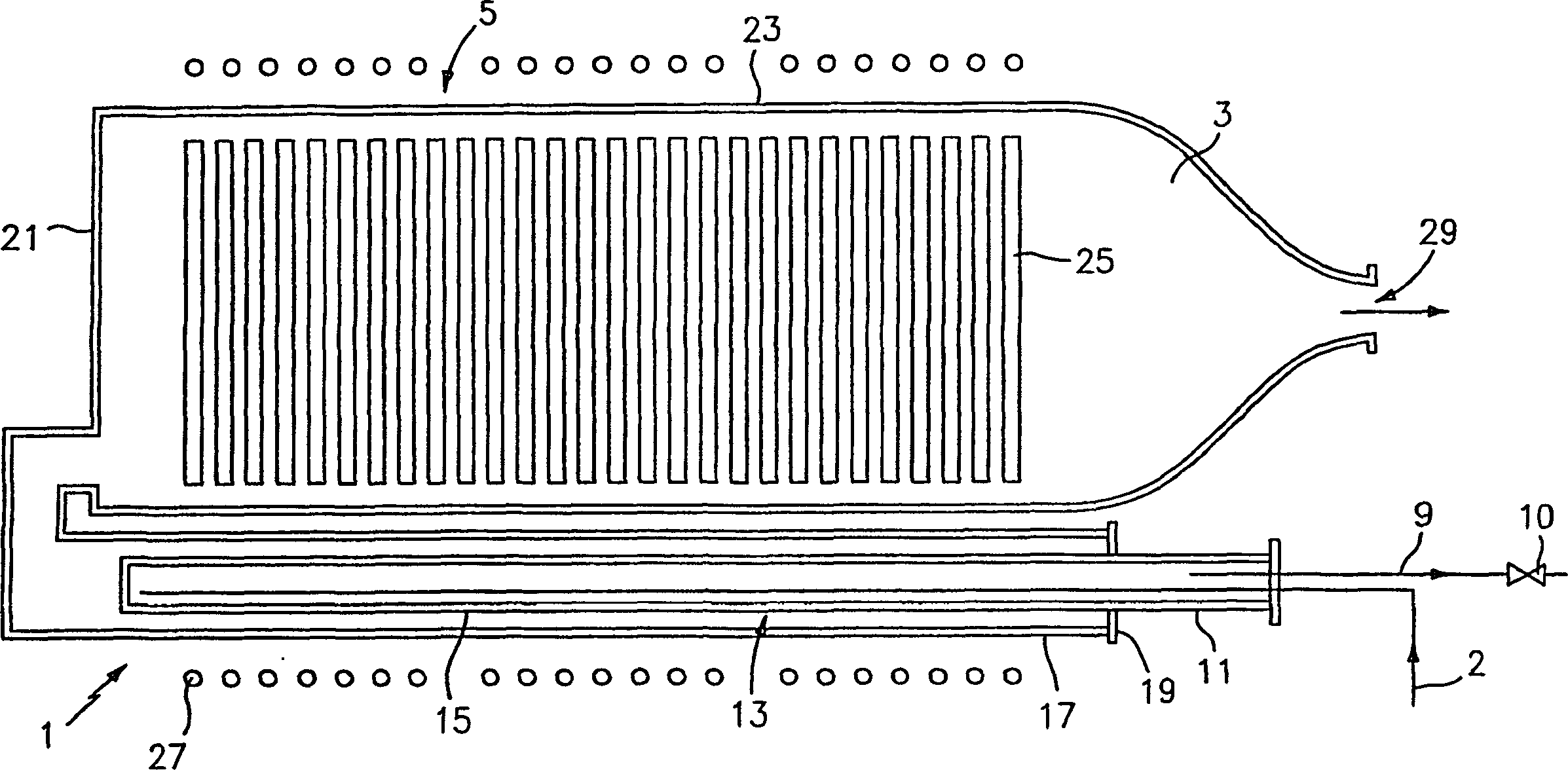

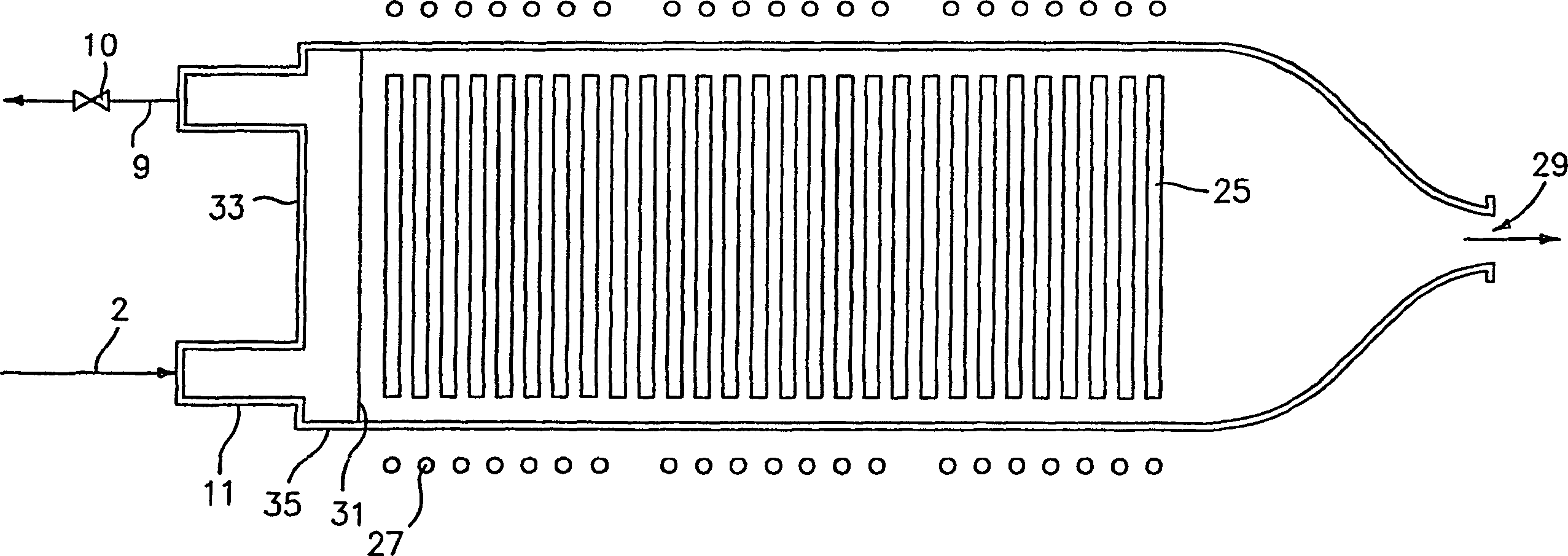

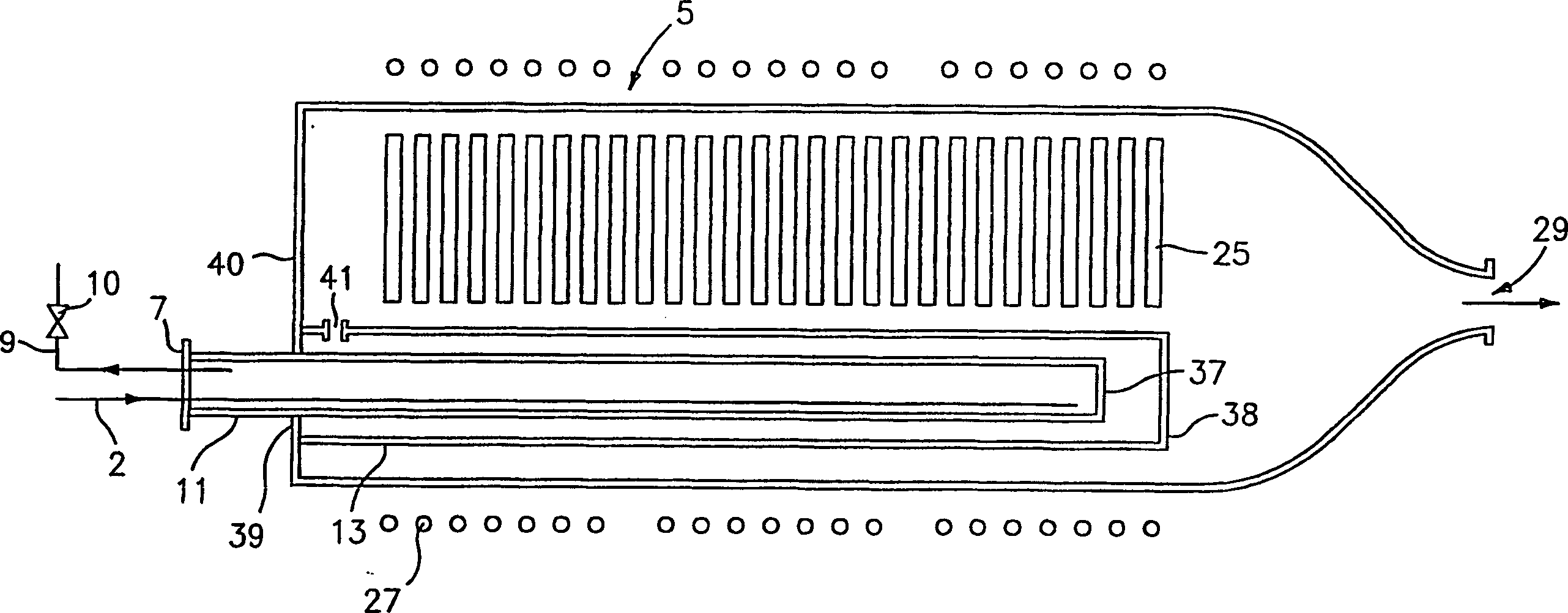

[0059] The calculations of this example were performed under the assumption that an oxygen transport membrane cell was used to produce ultra-high purity oxygen at 5 L / min. For the purposes of these calculations, the membrane used is a mixed conductor ceramic membrane with the following properties:

[0060] Membrane properties on porous substrates

[0061] thin oxygen selective membrane

[0062] Substrate porosity 40%

[0063] Effective film thickness 40microns

[0064] Oxygen ion conductivity 0.5s / cm

[0065] Operating temperature (isothermal) 900°C

[0066] These models represent some of the different possible configurations assuming the ceramic membrane tube is made 6 feet long and 1 inch in diameter. By minimizing the total number of ceramic membrane tubes that must be employed, and maximizing oxygen recovery, these configurations are achievable with low capital capital and low additional operating costs....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com