Sputtering device

A sputtering equipment and sputtering technology, used in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problem of uneven thickness of ITO film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

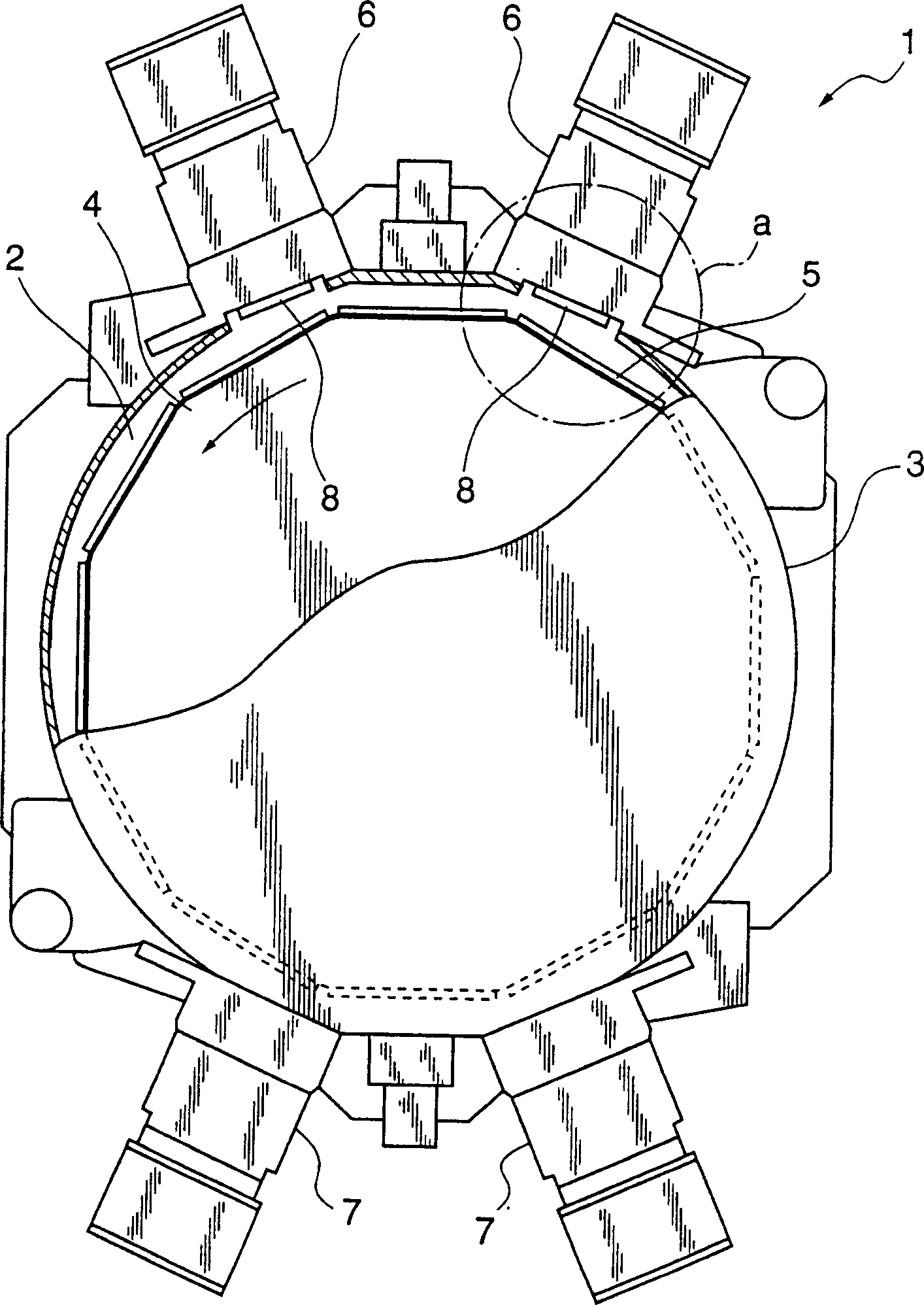

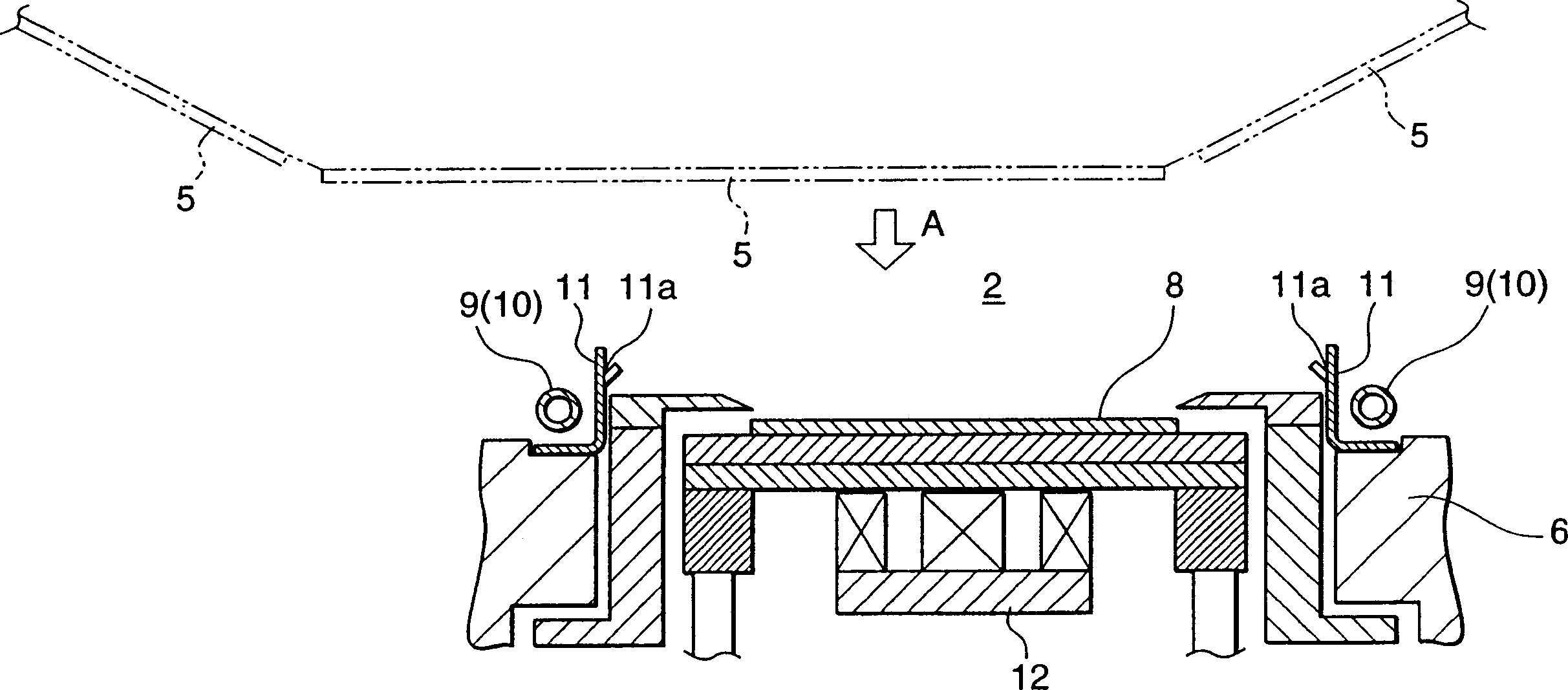

[0065] figure 1 is a partially cutaway plan view of a main body portion of a sputtering apparatus according to a first embodiment of the present invention.

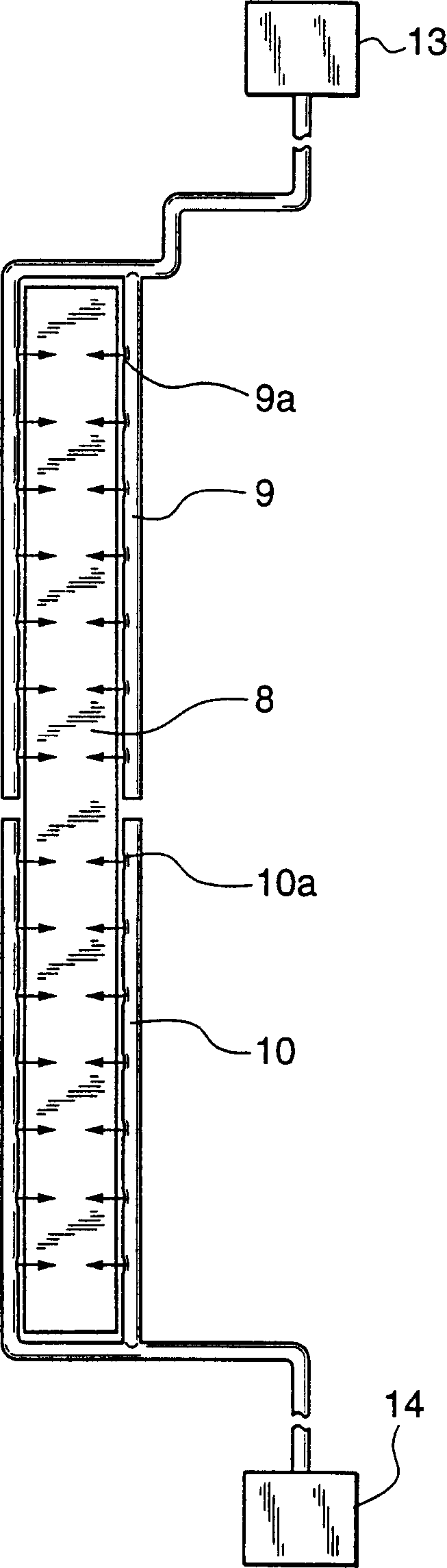

[0066] exist figure 1 Among them, the sputtering device 1 includes a housing 3 that forms a vacuum chamber 2 inside, and is located in the center of the housing 3 through a motor (not shown) along the figure 1 The dodecagonal rotating disc (substrate holder) 4 that rotates in the direction indicated by the arrow, a pair of ITO cathodes 6 that are used as sputtering cathodes at the peripheral side of the housing 3, and a pair of ITO cathodes that are connected to the ITO cathodes 6 Relative SiO 2 Cathode 7.

[0067] A plurality of substrates 5, for example four substrates 5, are arranged in a row on each side of the rotary disk 4 in the vertical direction. Each substrate 5 is a rectangular color filter substrate with a vertical dimension of 300 to 500 mm and a horizontal dimension of 400 to 600 mm, wherein a color f...

no. 2 example

[0130] Figure 11 is a partially cutaway plan view of a main body portion of a sputtering apparatus according to a second embodiment of the present invention.

[0131] exist Figure 11 Among them, the sputtering equipment 100 is formed by a housing 102 of a vacuum chamber 101 inside, and is located in the center of the housing 102 through a motor (moving device) (not shown) along the Figure 11 12 prismatic rotating discs (substrate holder) 103 that rotate in the direction shown by the arrow, a pair of ITO cathodes 104a and 104b that are used as sputtering cathodes at the peripheral side portion of the housing 102, and a pair of ITO cathodes with ITO Cathode 104a and 104b opposite SiO 2 Cathode 105a and 105b.

[0132] A plurality of substrates 106, for example four substrates 106, are arranged in a row on each side of the rotating disk 103 in the vertical direction. Each substrate 106 is a rectangular color filter substrate with a vertical dimension of 300 to 500 mm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com