Positive active material for lithium secondary battery and method of preparing the same

A technology for positive electrode active materials and lithium secondary batteries, which is applied in secondary battery manufacturing, secondary battery, electrode manufacturing, etc., and can solve the problems of failure to overcome the degradation of cycle life characteristics under high temperature, and failure to overcome capacitance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

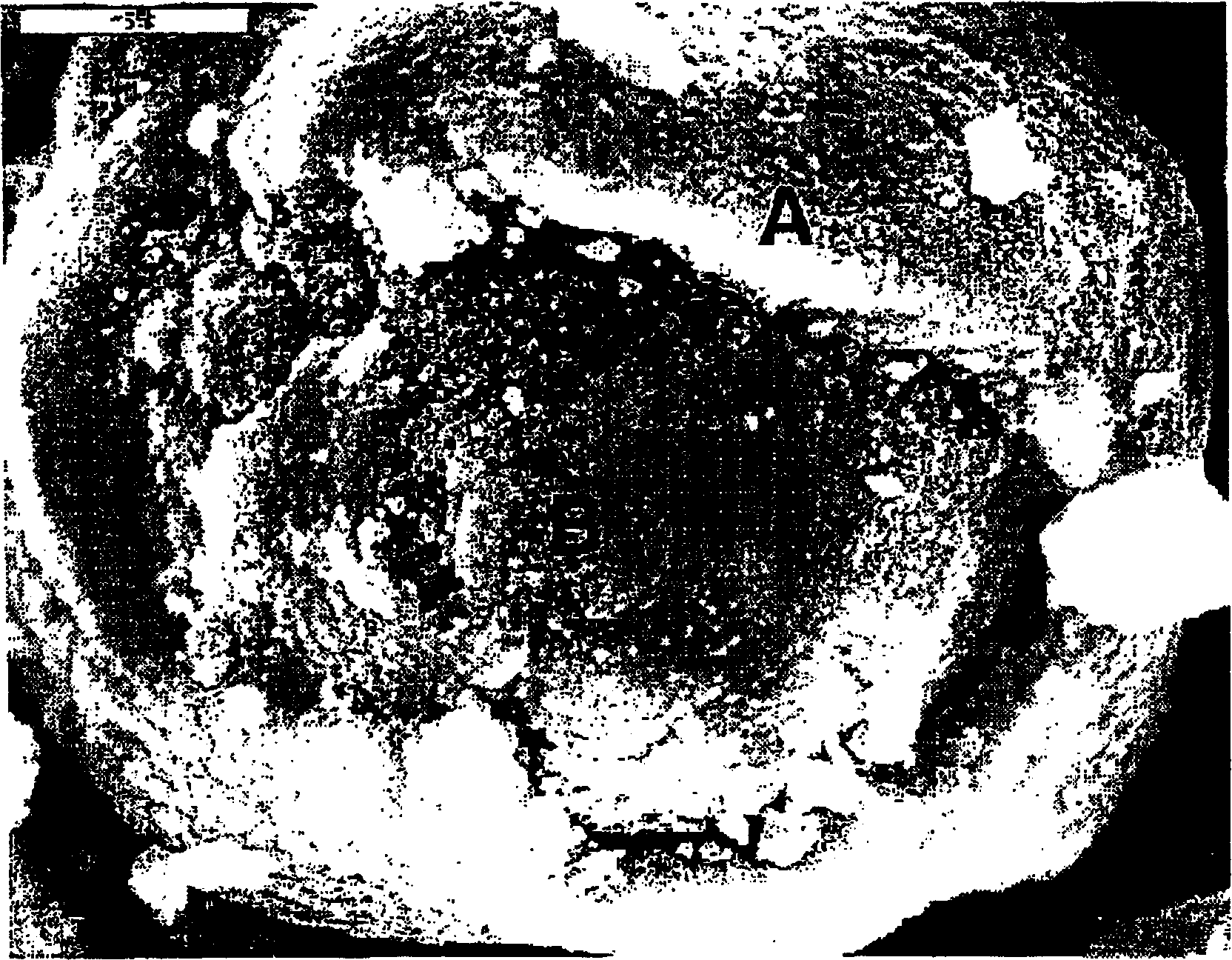

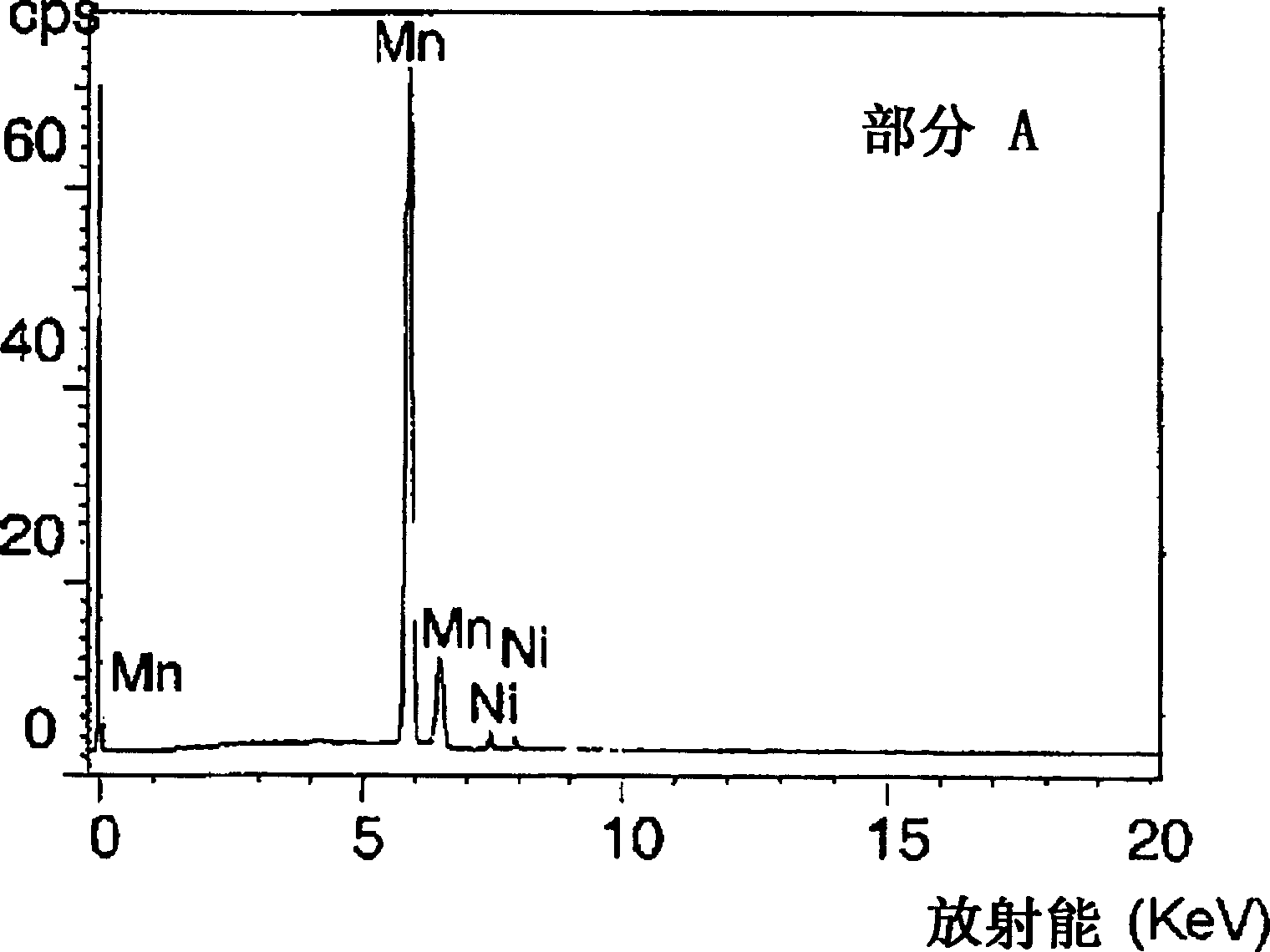

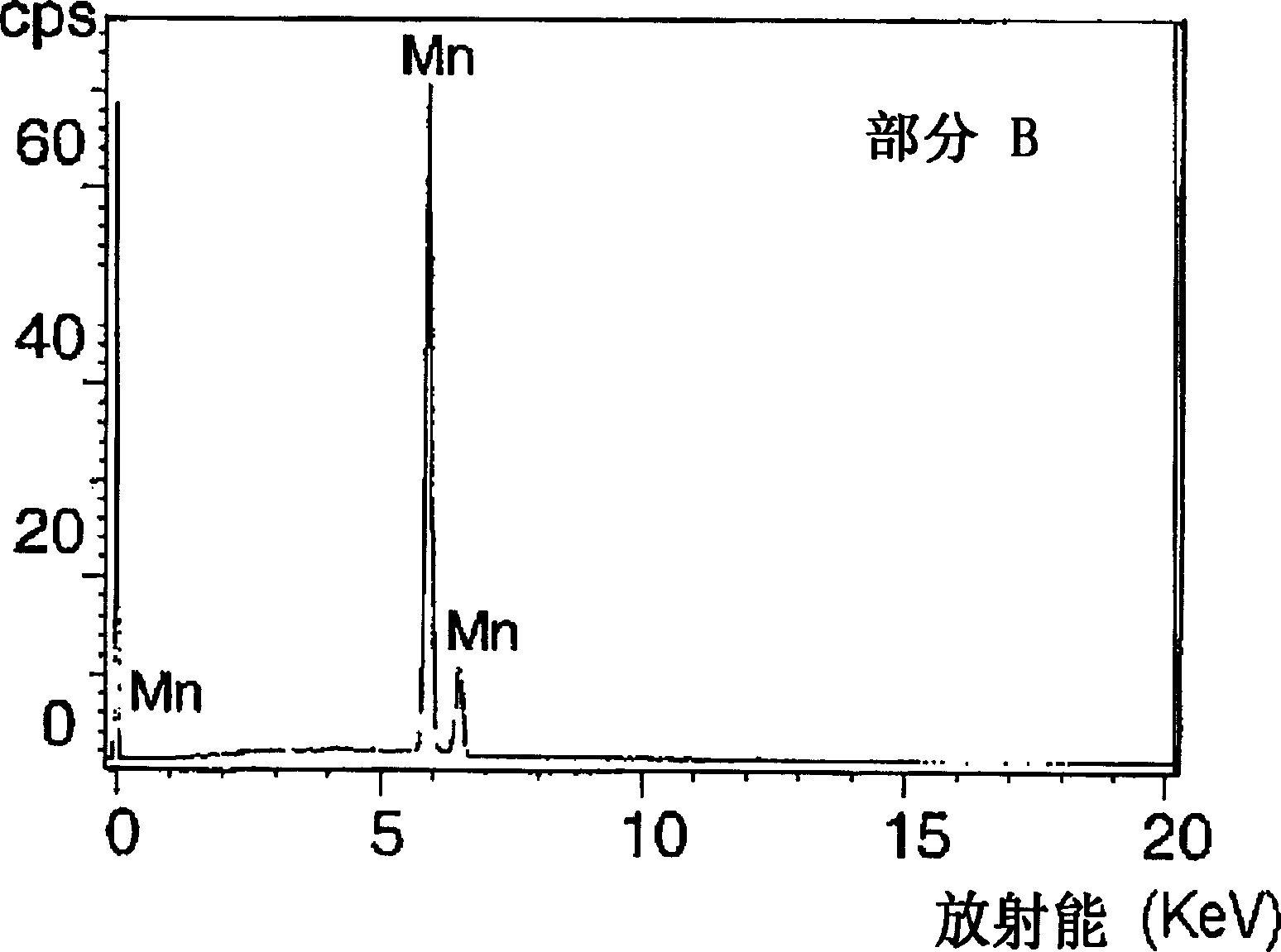

Image

Examples

Embodiment 1

[0065] (Preparation of core particles)

[0066] Will Li 2 CO 3 And MnO 2 The spinel lithium manganese composite powder was prepared after mixing with the molar ratio of Li and Mn as 0.538. After the above materials are uniformly mixed, they are heat-treated at 480°C for 10 hours in the air, then the material is cooled to accelerate the reaction, and then heat-treated at 750°C for 20 hours in the air to obtain spinel powder. The air flow rate in the heat treatment process is 0.1 l / Gh. The composition of the lithium manganese compound prepared by the above procedure is Li 1.05 Mn 1.95 O 4 .

[0067] (Preparation of outer layer material)

[0068] LiCH 3 COO is used to provide lithium as the outer layer material, Ni(CH 3 COO) 2 Used to provide Ni, and Co(CH 3 COO) 2 Used to provide Co. The homogeneous composite solution of the lithium-nickel metal composite compound is prepared by stirring the absolute ethanol solution in which...

Embodiment 2

[0083] The preparation and testing of the positive electrode and the test battery were performed in the same method as in Example 1, except that the molar ratio of Ni and Co of the outer layer composition was 4:6.

Embodiment 3

[0085] The preparation and testing of the positive electrode and the test battery were carried out in the same way as in Example 1, except that the outer layer composition was LiNi 0.7 V 0.3 O 2 outer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com