Method for producing modified nylon 6 pellet (special for fishing net)

A production method and technology for special materials, which are applied in the production field of nylon 6 modified chips (special materials for fishing nets), can solve the problems of foreign exchange costs and unsatisfactory effects, and achieve the effect of improving the fishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

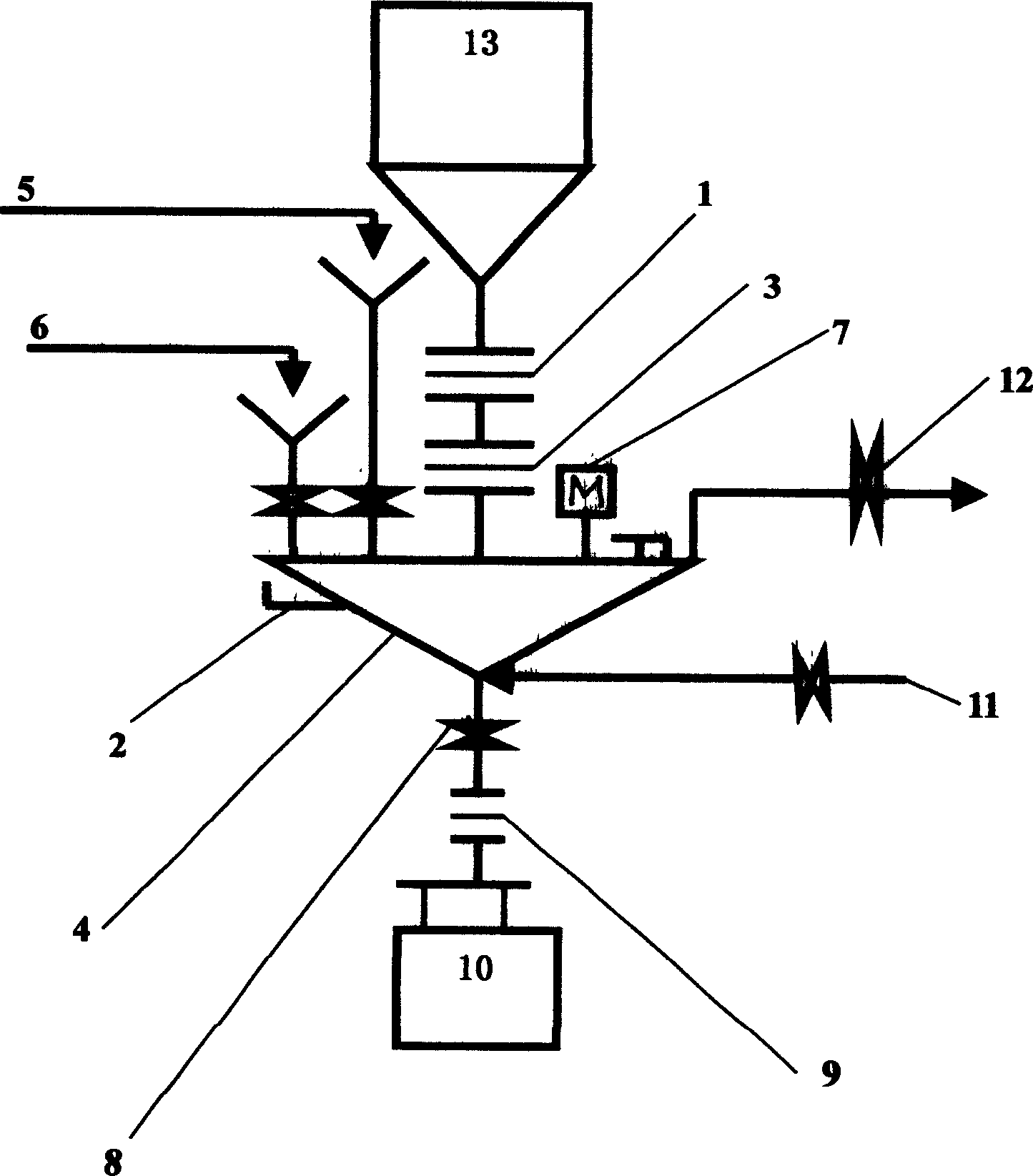

[0016] 1. Open the outlet hand valve (1) of the slicing bin (13).

[0017] 2. Start the metering scale (2), open the slice inlet pneumatic slide valve (3), and the slices will fall into the mixer (4). When the metered slice volume is 1000Kg, close the slice inlet pneumatic slide valve (3).

[0018] 1. Manually add 4Kg of transparent softener (cadmium stearate) and 0.15Kg of dispersant (white oil) through feeding ports (5) and (6).

[0019] 2. After starting the mixer (7) for 12 minutes, stop stirring and open the electric valve (8) at the outlet of the mixer.

[0020] 3. Open the slice outlet pneumatic slide valve (9), send the evenly mixed slices to the packaging line (10), and pack them into 25Kg / bag.

[0021] 4. After packing, start the nitrogen inlet and outlet valves (11) and (12) to purge and replace the system.

[0022] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com