Method of rolling worm gear and worm gear

A processing method and technology of worm, applied in the field of worm, can solve the problem of inability to completely prevent penetration feed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

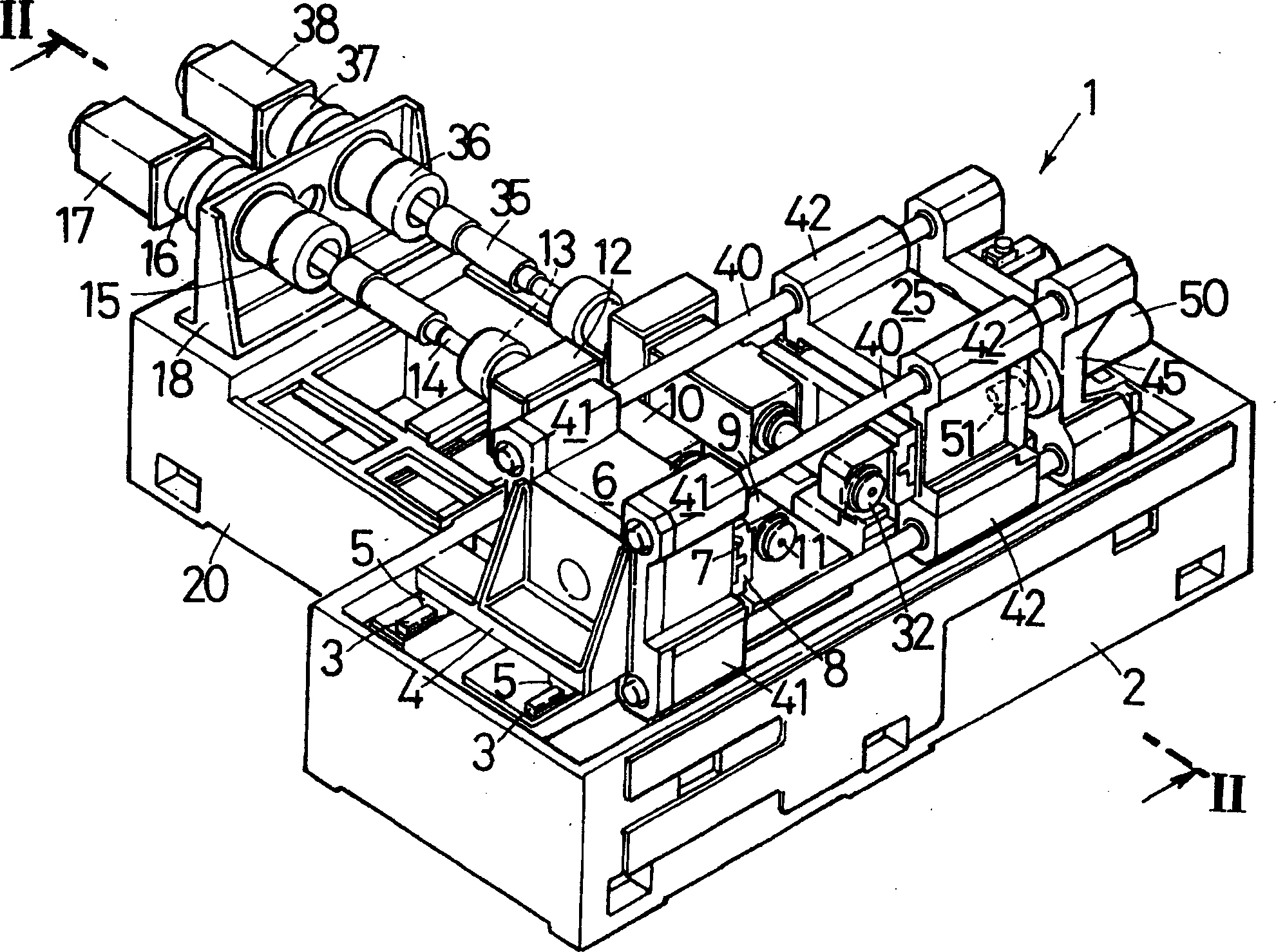

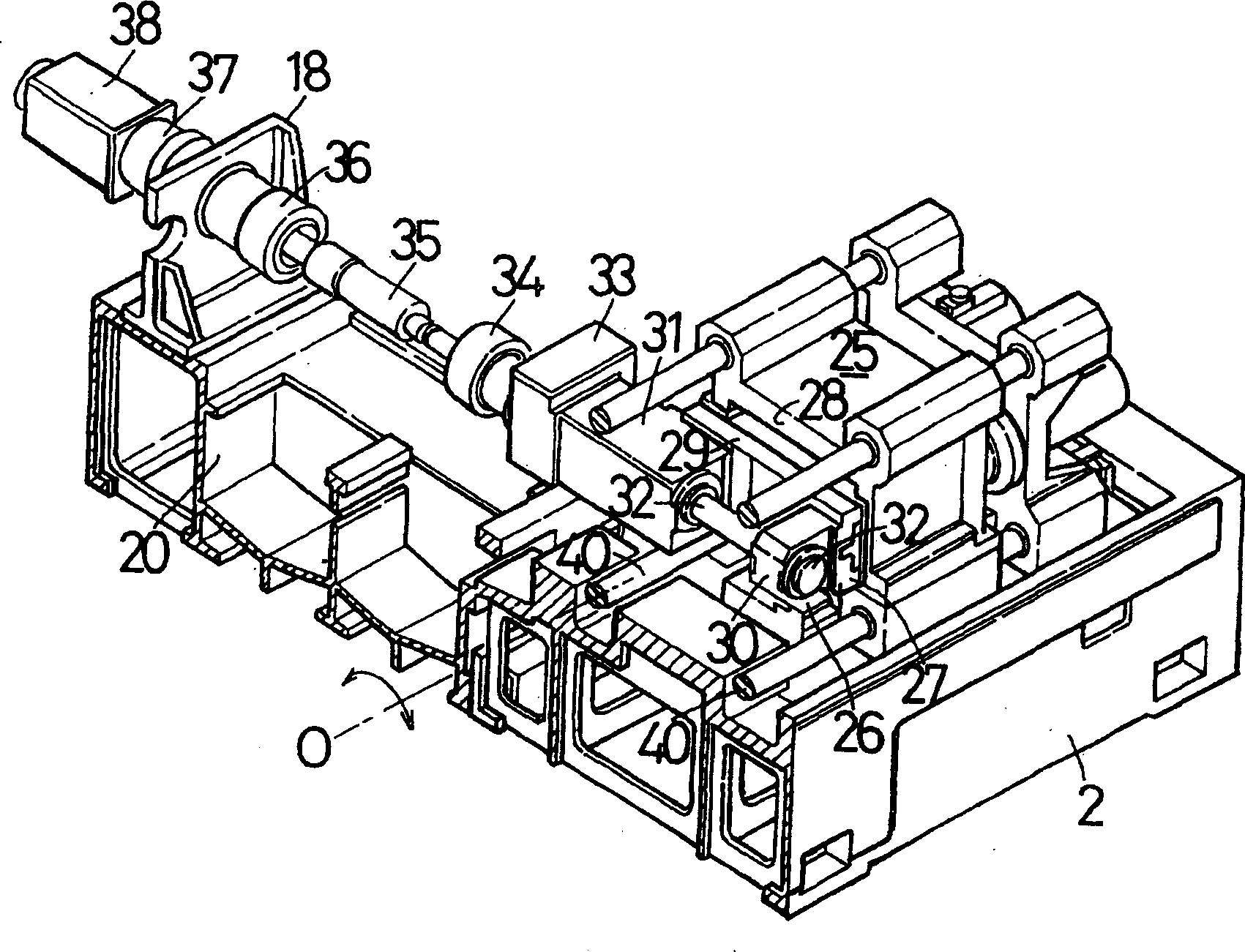

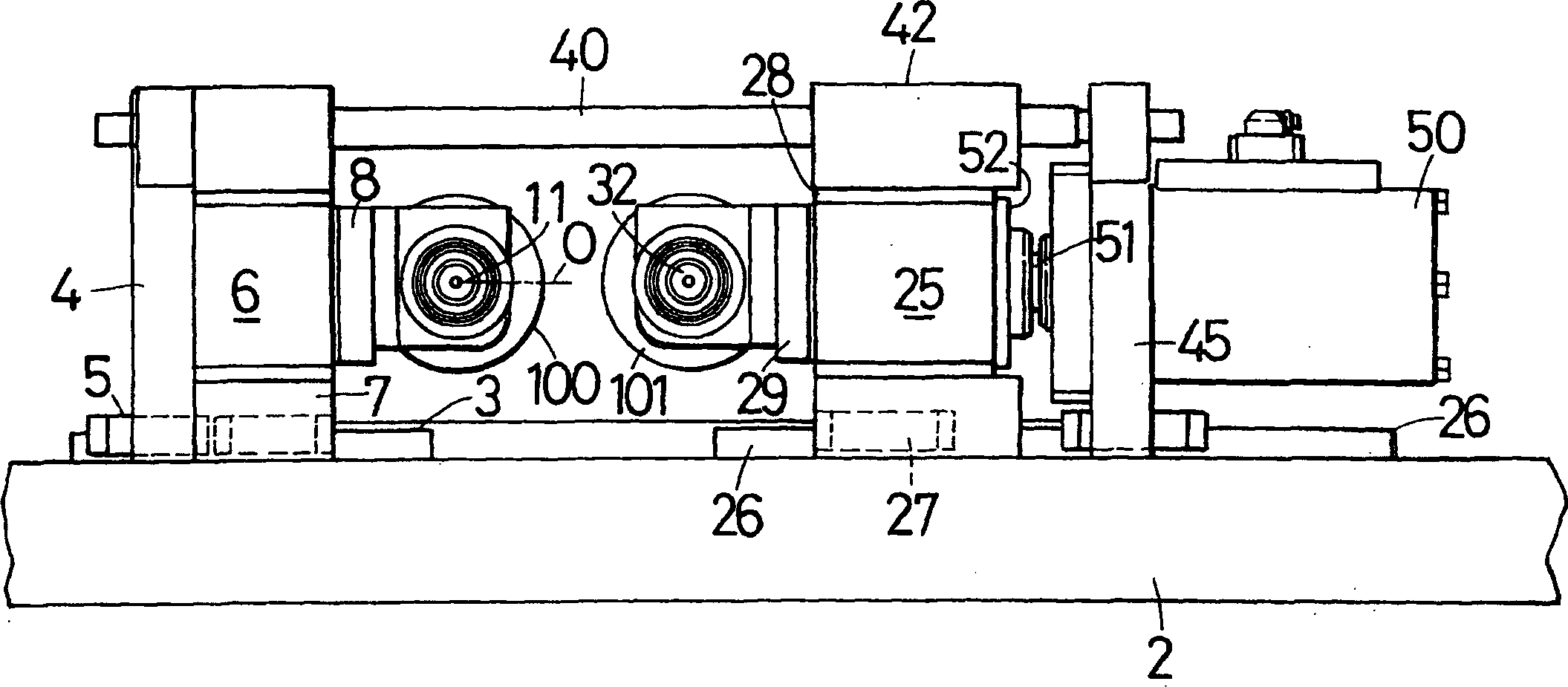

[0037] Next, examples embodying the present invention will be described. figure 1 It is an overall perspective view showing a rolling machine for rolling the worm of the present invention. figure 2 yes figure 1 Partial sectional view of II-II. image 3 is the front view of the rolling mill. Figure 4 is a cutaway top view. The rolling mill 1 is a circular rolling mill for plastically deforming a billet by arranging cylindrical molds facing each other. In a common round die rolling machine, a movable die to be driven to rotate and a fixed die driven to rotate by it are arranged opposite to each other with their rotation axes parallel to each other, and a billet is placed between them.

[0038] The rolling machine 1 for machining a worm according to the present invention synchronously drives and rotates two round dies in the same rotation direction during machining. The detailed structure will be described below. The base 2 constitutes the body of the rolling mill 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com