Bamboo shoots shucking machine

A bamboo shoot peeling machine and a technology of peeling machine are applied in the fields of vegetable or fruit peeling, food science, application, etc., which can solve the problems of high labor cost and time-consuming, and achieve the reduction of labor cost, accurate peeling, and improved peeling. The effect of removing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

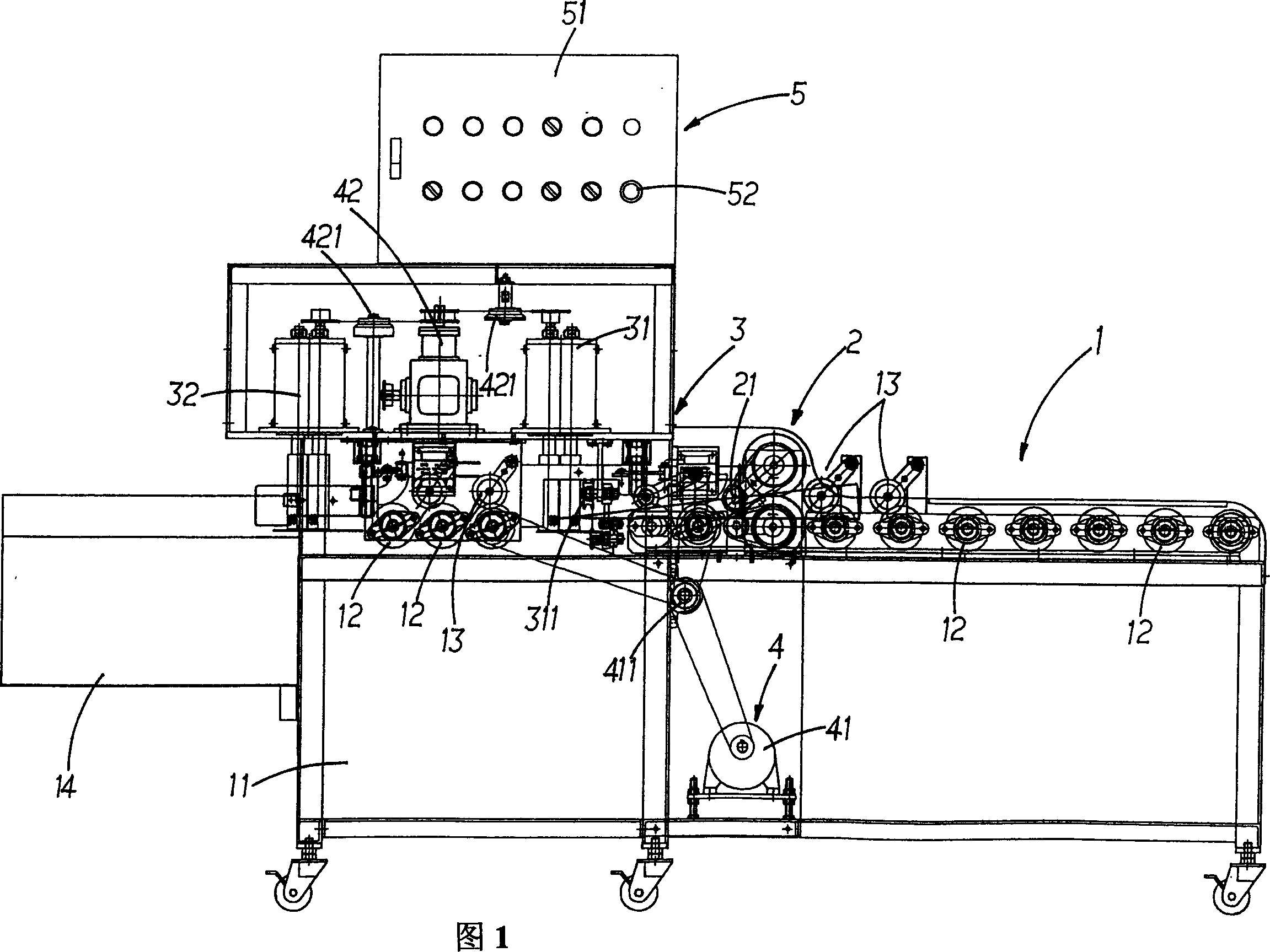

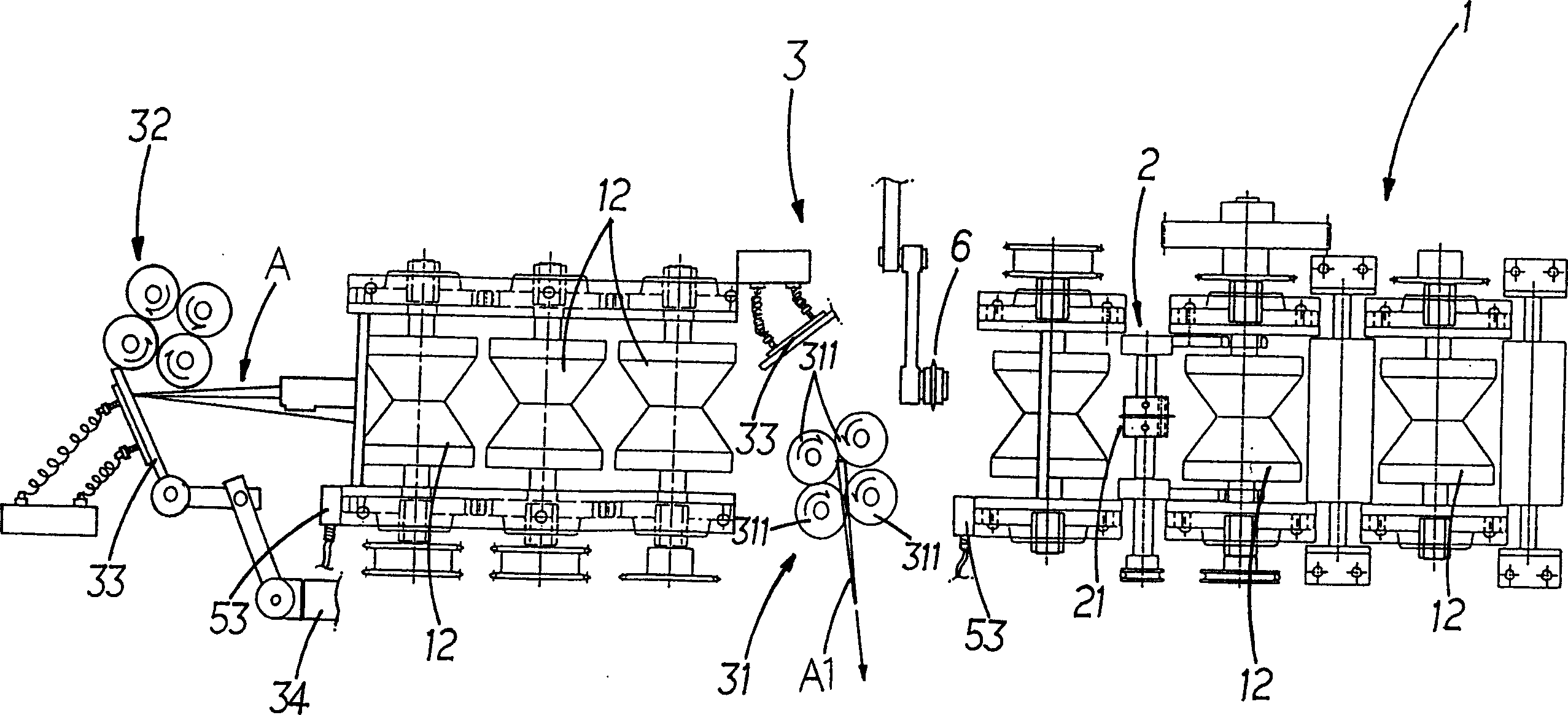

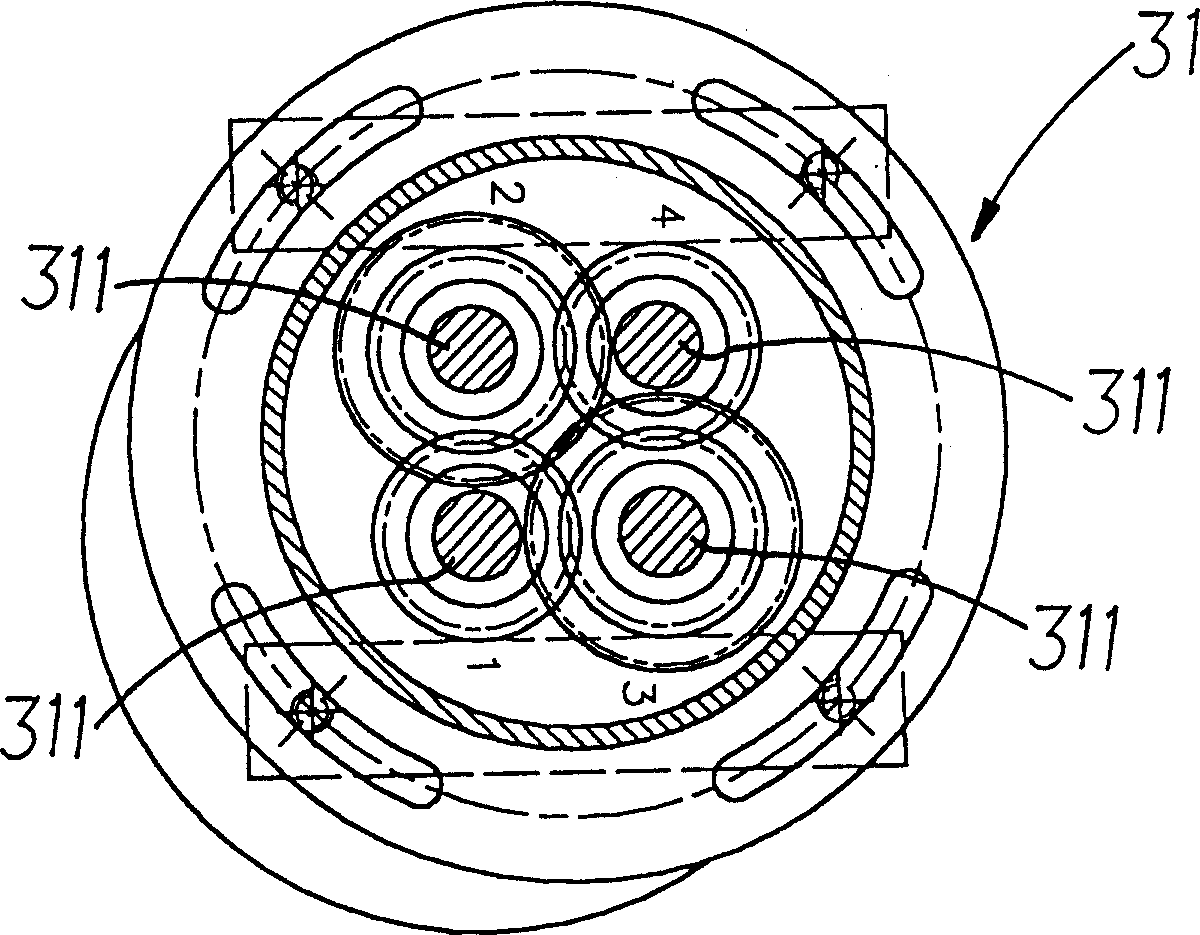

[0017] Bamboo shoot peeling machine of the present invention, the main structural composition of its integral peeling machine is as Fig. 1 and figure 2 As shown, it includes: a conveying unit 1, a shell splitting unit 2, a shell stripping unit 3, a driving unit 4, and a control unit 5; wherein, the conveying unit 1 is mainly composed of a machine 11 for The main body, and on the machine platform 11, according to the direction in which the bamboo shoots are expected to be transferred, a number of conveying rollers 12 are arranged at appropriate intervals for the bearing of the bamboo shoots A, and the conveying motor 41 in the driving unit 4 is coordinated by the chain and the chain. The transmission assembly 411 formed by the wheels is connected and driven to make the conveying rollers 12 rotate synchronously to achieve the effect of conveying the bamboo shoots A, and a receiving groove 14 is provided at the end of the machine table 11 to hold the bamboo shoots A to complete th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com