Engine starter

An engine starting and engine technology, which is applied to the starting of the engine, the starting of the engine with an electric motor, the engine components, etc., can solve the problems of distinguishing the exhaust stroke and the compression stroke, the high cost of the device, and the opposite relationship between the cycle sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

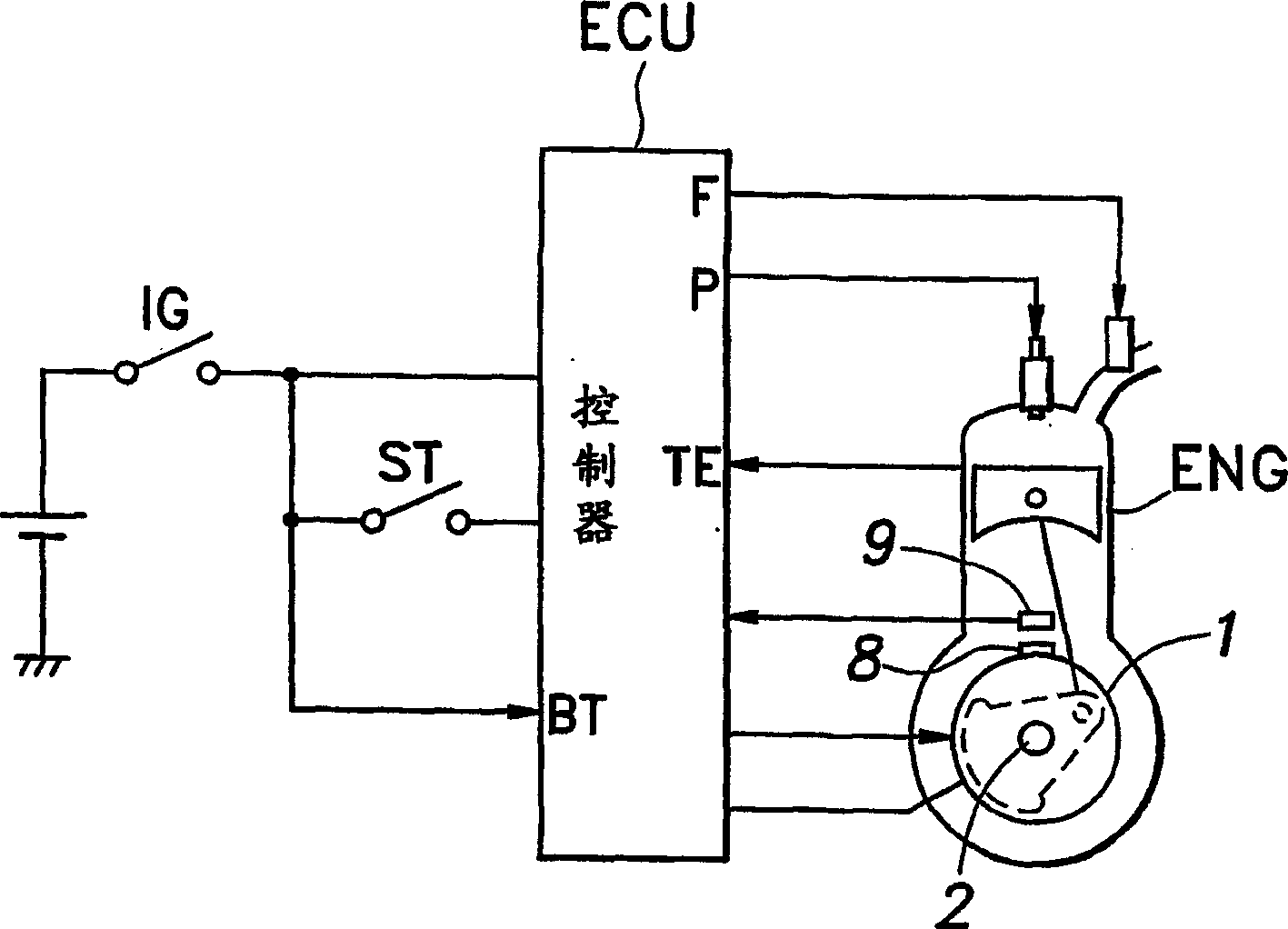

[0047] figure 1 It is a schematic configuration diagram of an engine starting device to which the present invention is applied. like figure 1 As shown, the electric motor (generator) 1 of this starting device is set under the state of being directly connected coaxially with the crankshaft 2 of the four-stroke engine ENG, and is used as a generator while rotating the power output shaft at the time of starting. Used while the engine is running. Then, signals from an ignition switch IG and a starter switch ST are input to a controller ECU that controls the electric motor 1 and the engine ENG. Then the ignition signal P and the fuel injection signal F are output from the controller ECU to the engine ENG.

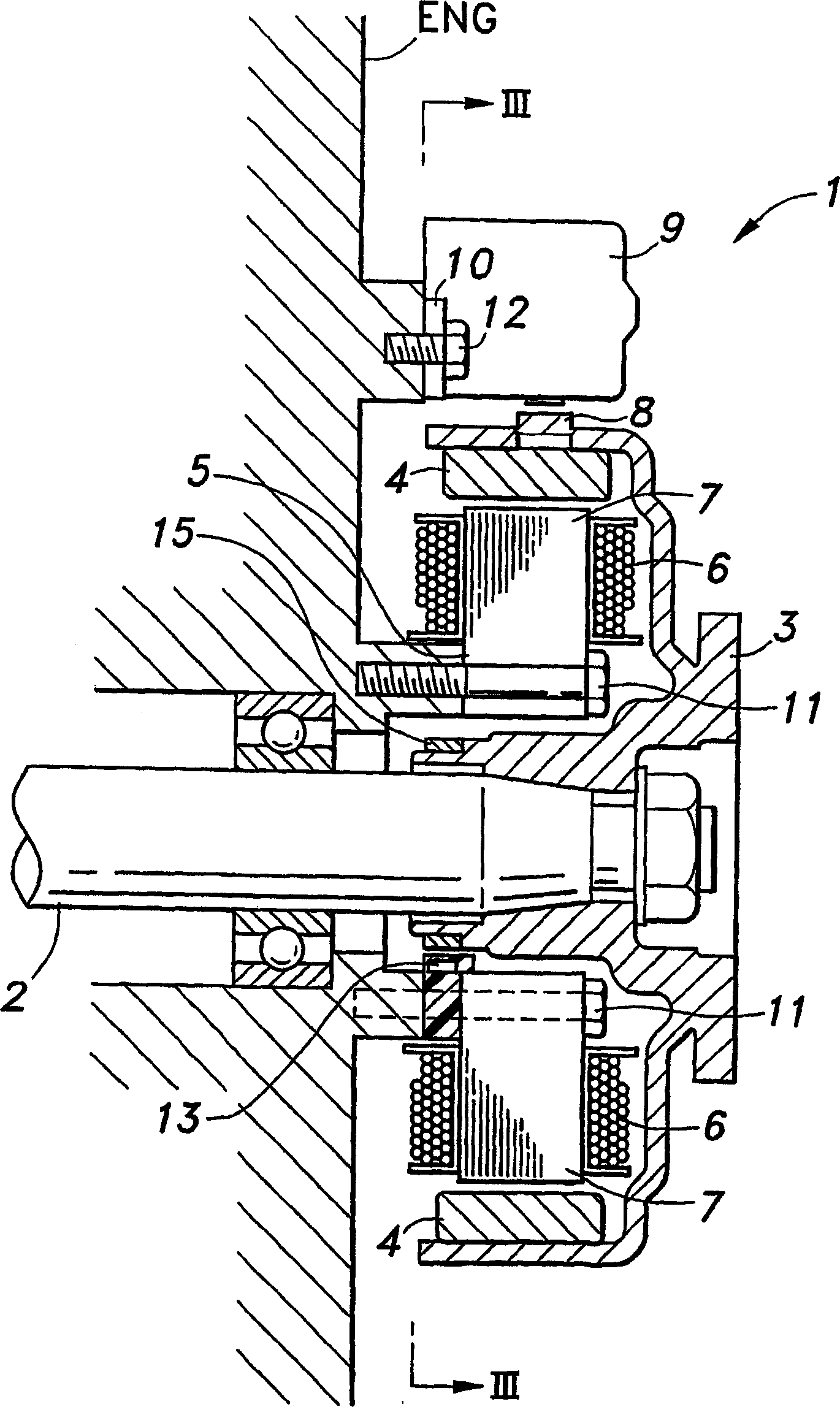

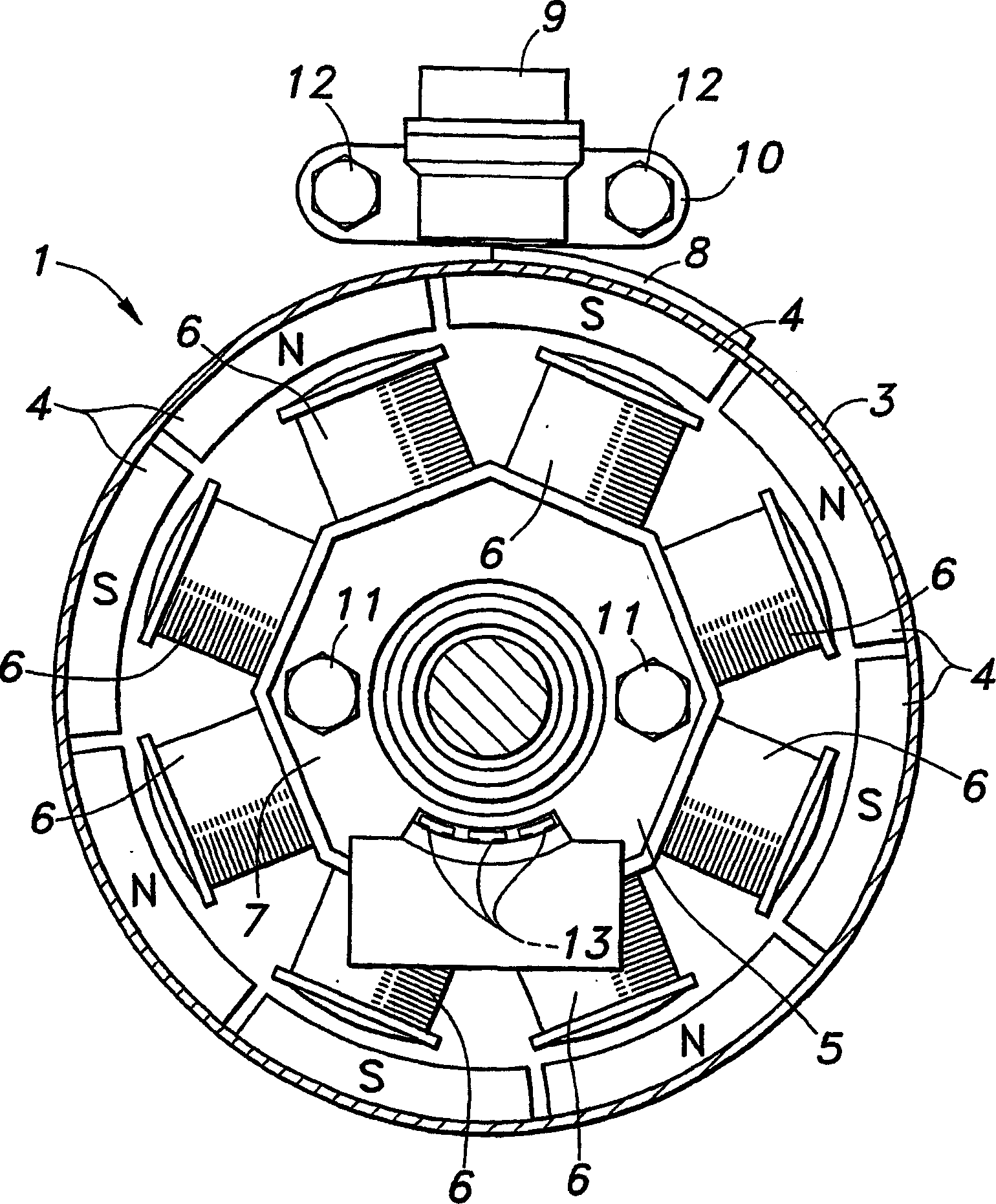

[0048] refer to figure 2 and image 3 The structure of the generator 1 will be described as follows. As shown in the figure, the electric motor 1 is coaxially fixed on the crankshaft 2 of the engine ENG, and a flat bottomed cylindrical outer rotor 3 that doubles as a flyw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com