Start of switching reluctance generator

A technology of reluctance and starting winding, which is applied to the starter, motor generator/starter, synchronous generator, etc. of a single synchronous machine, which can solve the problems of hindering the starting system and unable to guarantee the capacity of the capacitor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

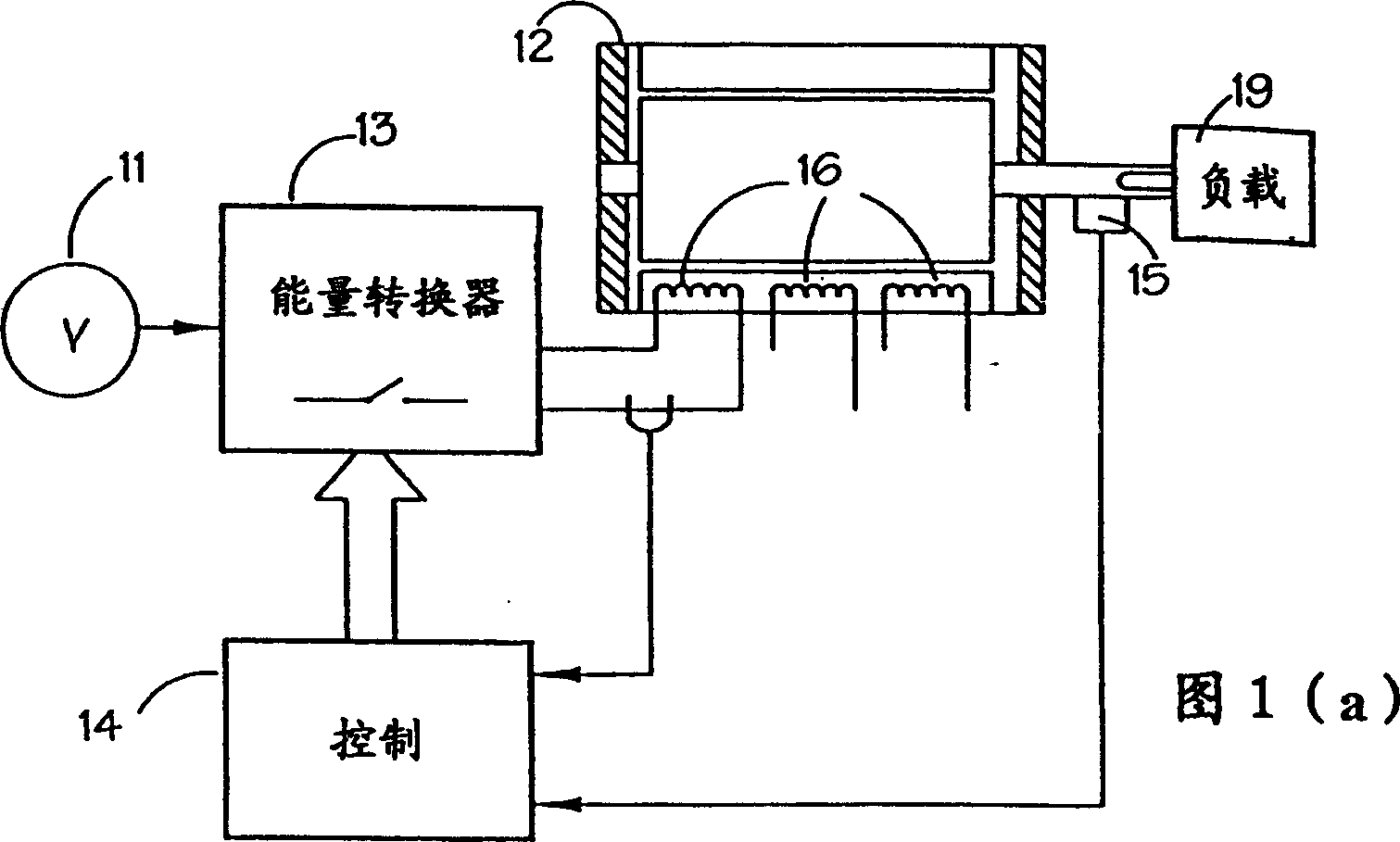

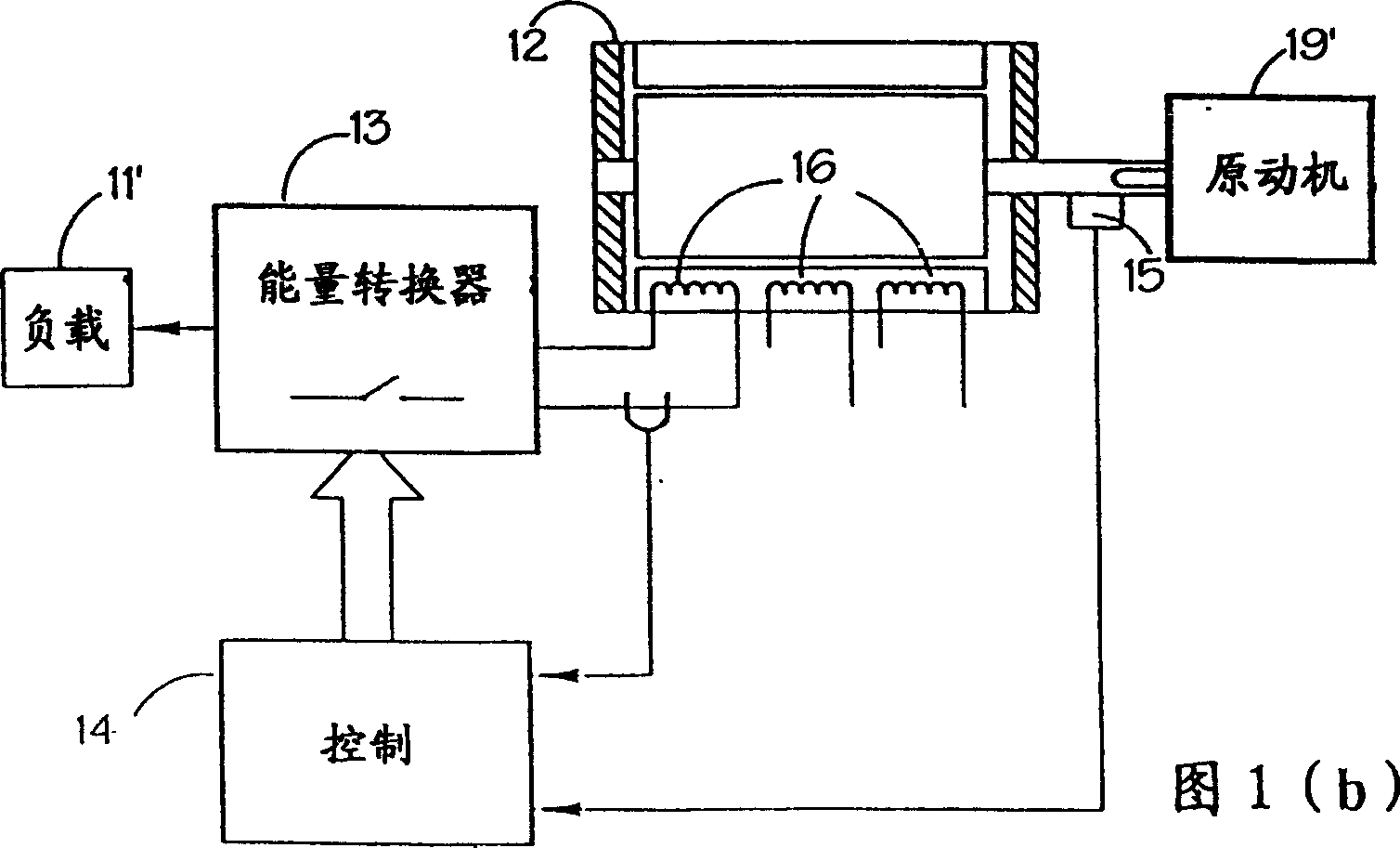

[0041] The Radun article cited above discloses a method of starting a switched reluctance generator, whereby the excitation energy initially comes from a battery, supplying the excitation bus to excite the phase windings of the machine. The generator returns all output to the bus until the bus voltage rises to a suitable value, then closes an additional thyristor switch to send the generator output to the load. Stable operation requires the use of an excitation bus and additional thyristors. A similar system with separate drive and load buses is disclosed in EPA 0564076.

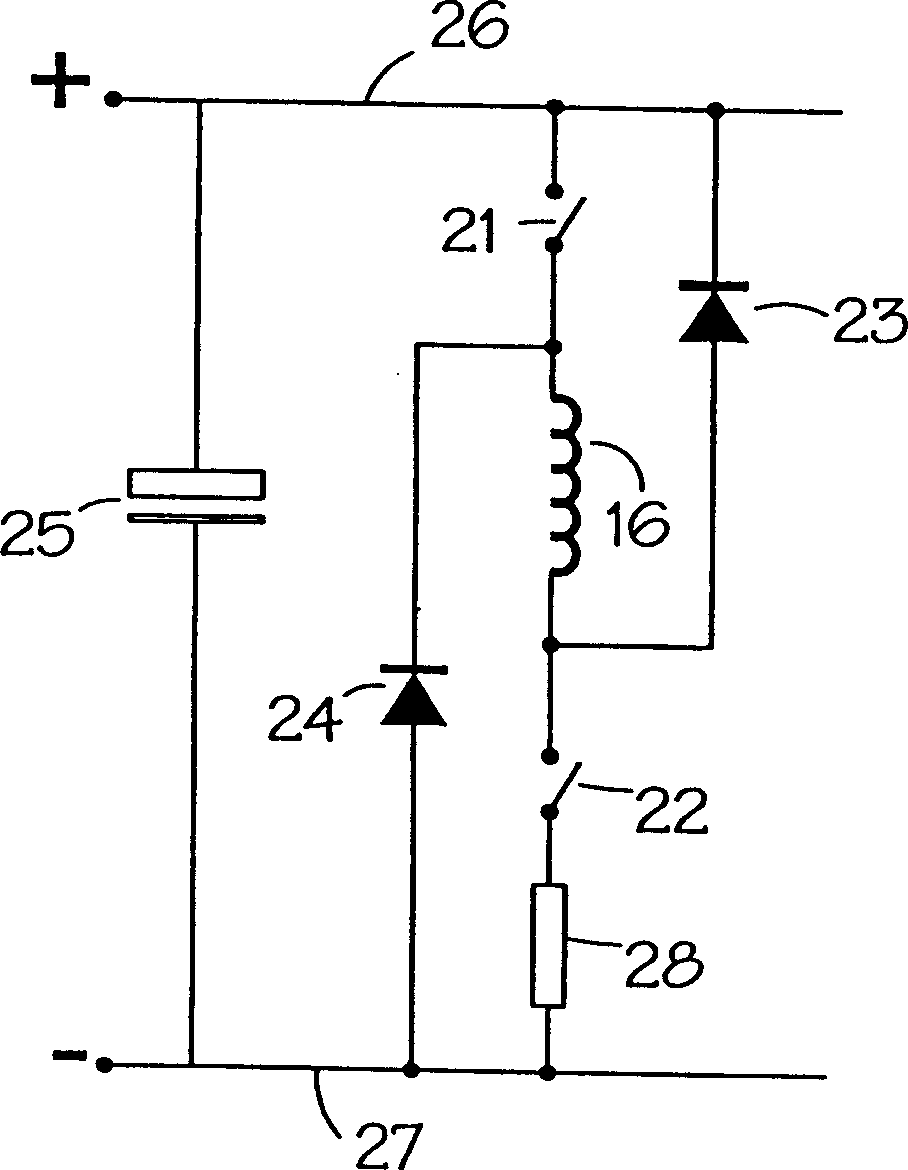

[0042] Unlike prior art systems, the present invention uses a single bus and a separate start winding to boost the DC link capacitor voltage. This is done by introducing an initial flux linkage within the machine, thus producing a DC link voltage sufficient to allow the generator to operate in conventional conditions. This system will be described in detail below.

[0043] Shown in Figure 6 is a cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com