Assembled high-voltage current transformer

A current transformer and high-voltage current technology, which is applied in the direction of inductors, transformers, circuits, etc., can solve the problems of high local field strength, increased cost, and difficult electric field, so as to achieve small impact of stray capacitance, improve product qualification rate, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

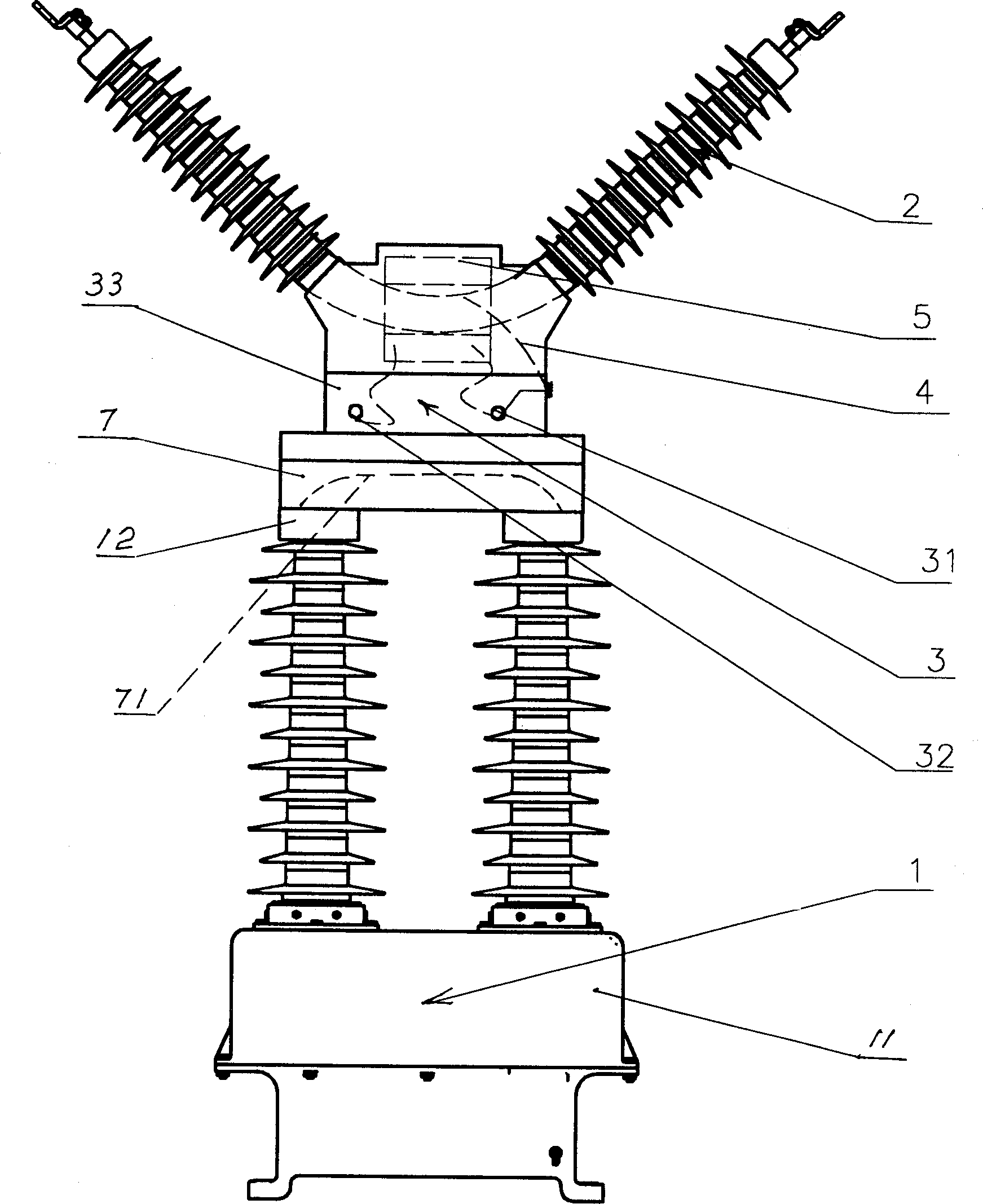

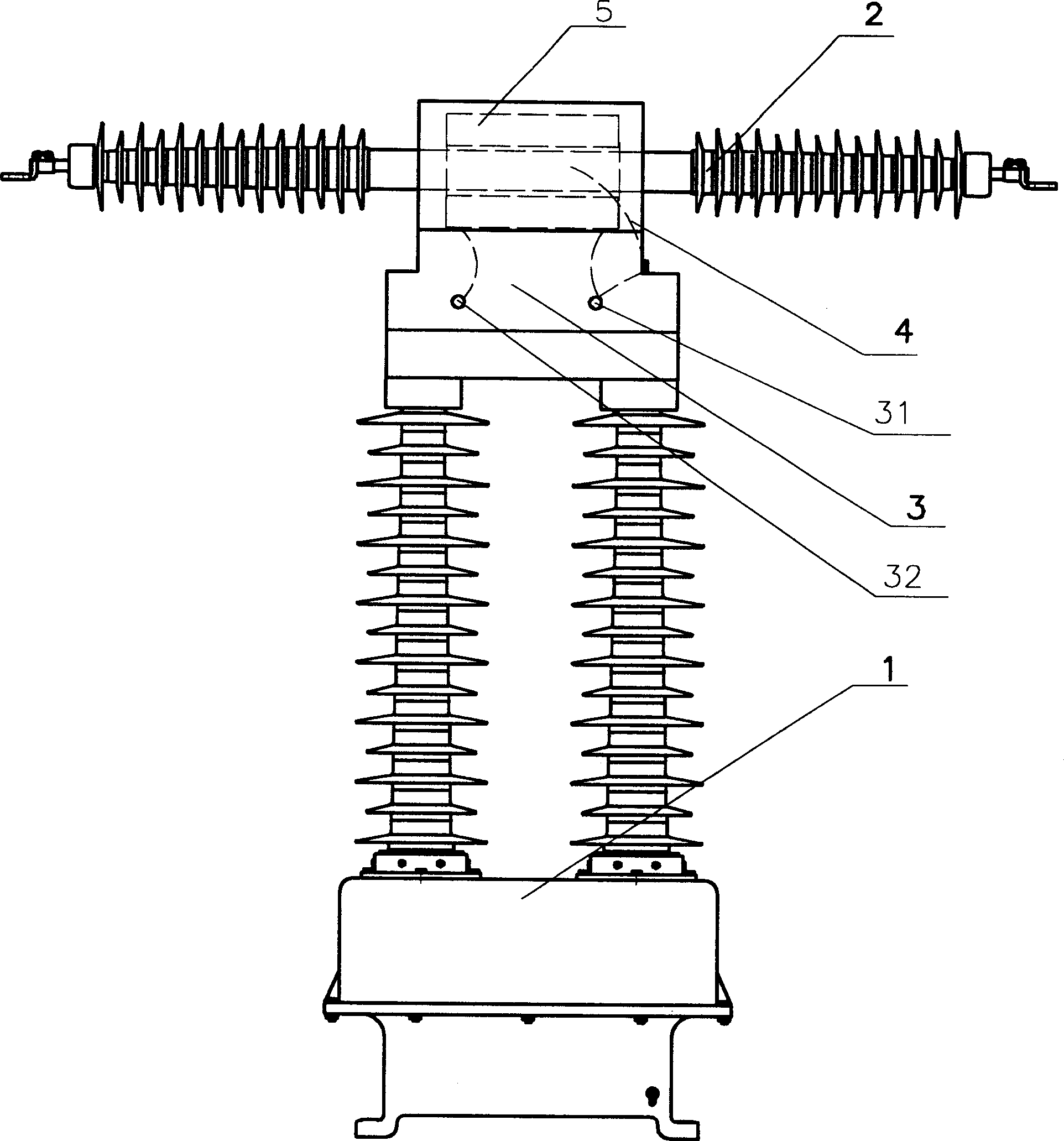

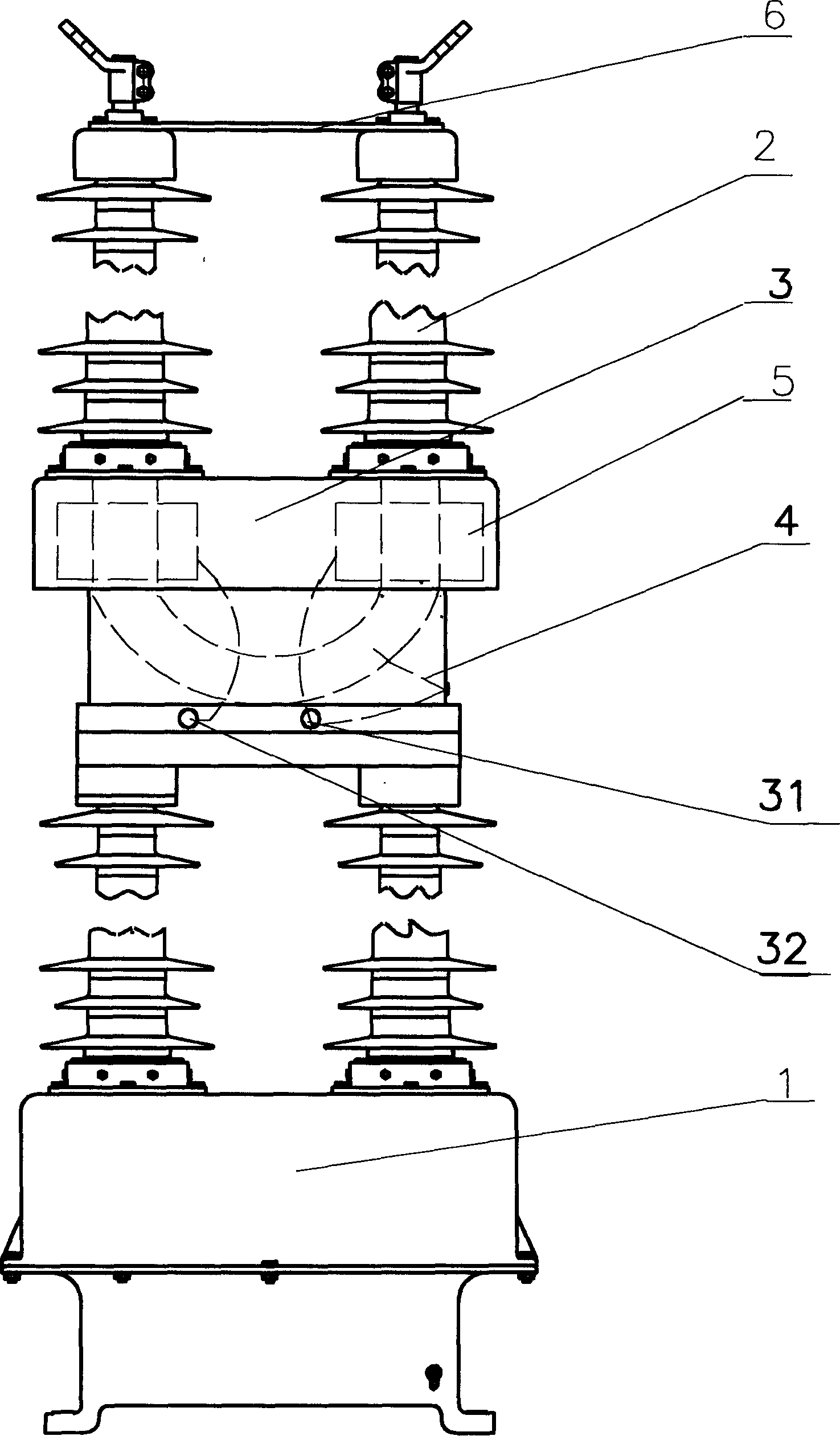

[0011] see figure 1 , which shows the first embodiment of the combined high-voltage current transformer of the present invention. It includes a combination of a capacitive high-voltage bushing 2 on the upper part, a low-voltage through-type current transformer 3 on the middle, and an independent high-voltage current transformer 1 on the lower part.

[0012] The independent high-voltage current transformer 1 is a dry-type high-voltage current transformer, the primary winding adopts a capacitive insulation structure, and has a multi-turn coil wound by mutually insulated wires. Its secondary winding is set according to the needs of users. The part of the primary winding protruding from the base 11 forms double arms extending upward in the vertical direction.

[0013] The capacitive high-voltage bushing 2 is generally V-shaped, and one end of the clamp can be connected to, for example, a substation isolation switch, and the other end of the clamp can be connected to, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com