Method and equipment for detecting single plate by JTAG

A technology of testing equipment and testing methods, which is applied in the direction of detecting faulty computer hardware, etc., can solve the problems of high cost, achieve the effects of avoiding losses, improving the correct rate of diagnosis, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

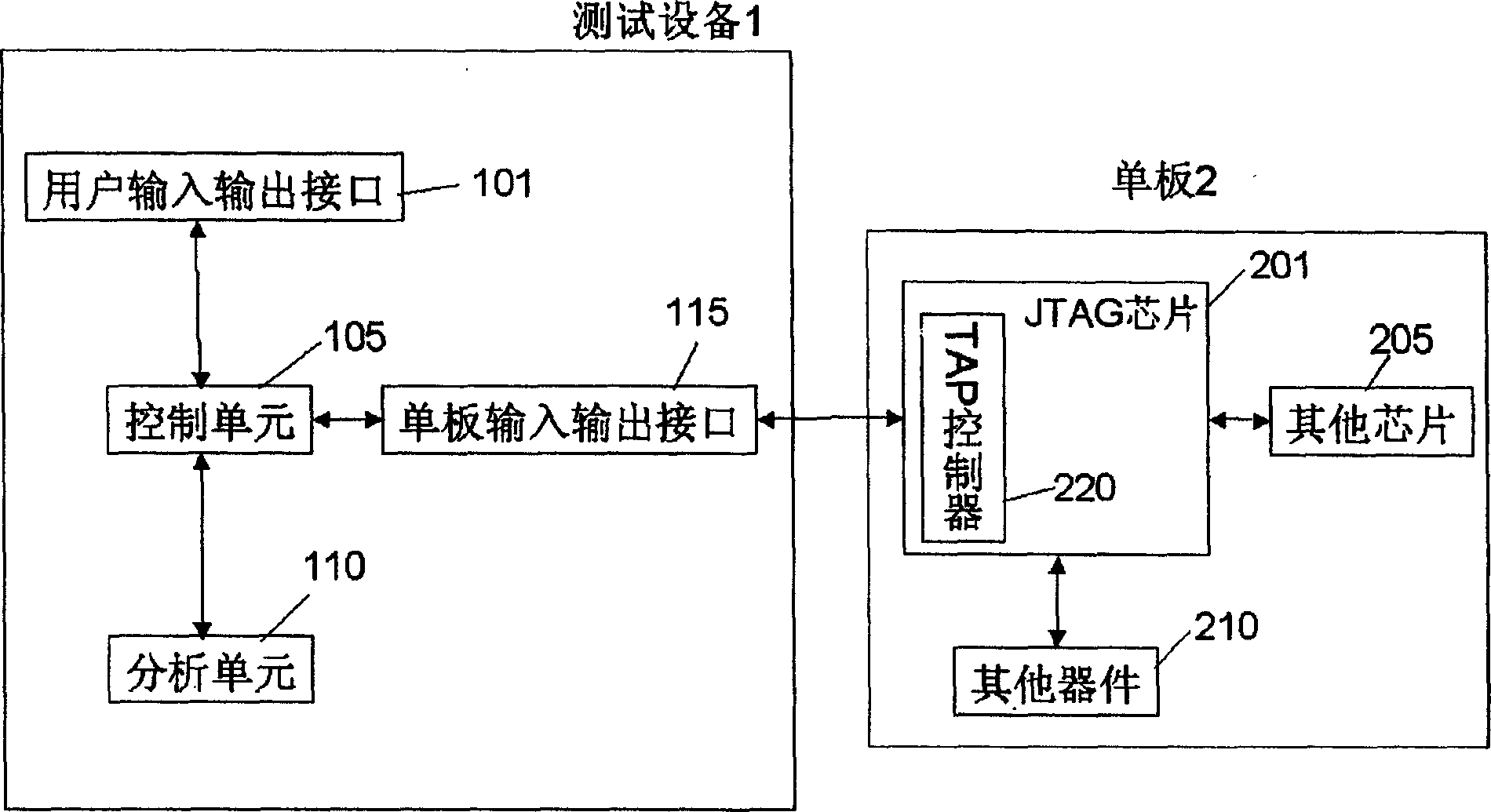

[0012] figure 1 A schematic view of a testing device according to the invention is shown.

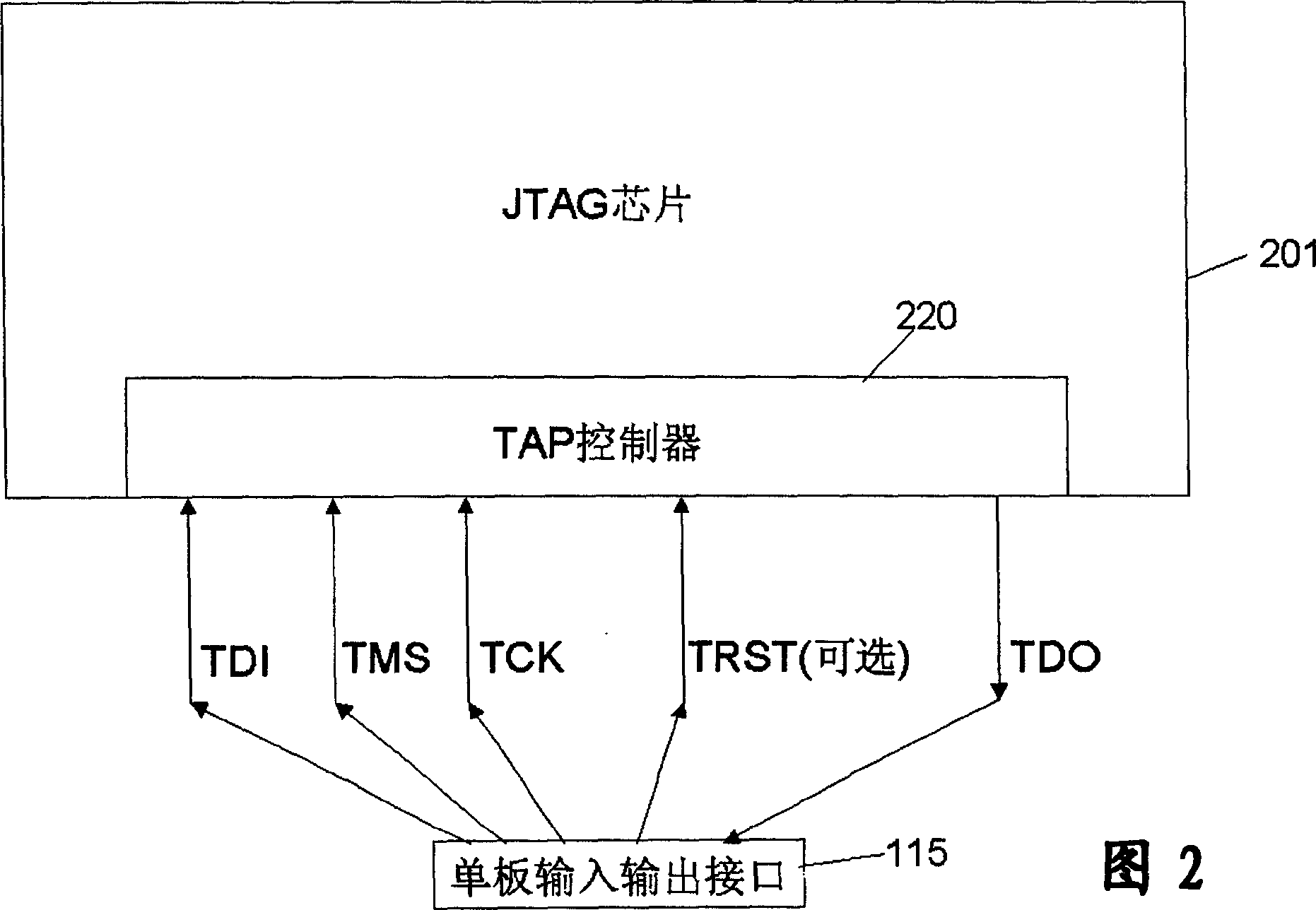

[0013] According to the present invention, in order to test the single board 2, a chip 201 (hereinafter referred to as the JTAG chip) supporting the JTAG function needs to be arranged on the single board 2, and the JTAG chip 201 includes a TAP (Test Access Port) controller 220, and the TAP controls The TAP control signal provided by the device 220 includes:

[0014] TCK: Test Clock test clock (input)

[0015] TDI: Test Data In test data input (input)

[0016] TMS: Test Mode Select test mode selection (input)

[0017] TDO: Test Data Out test data output (output)

[0018] TRST: Test Reset Test reset (input) (optional).

[0019] The above-mentioned TAP control signal is extracted from the TAP controller 220 on the JTAG chip for use by the present invention to test the single board under test.

[0020] Such as figure 1 As shown, in order to test the single board 2 with the JTAG chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com