Method for analyzing component temperature state by using carbide phase component change

A technology of change analysis and carbide, applied in the direction of analysis of materials, material thermal analysis, instruments, etc., to achieve the effect of accurate service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Select new materials of 102 steel and 12Cr1MoV steel, and pipe samples of different aging degrees obtained after actual use, and process them into simulated test samples.

[0014] The variable stress simulation test and the variable temperature simulation test under constant stress σ are carried out at a constant temperature T, and the test is stopped after a certain time of 100, 1000, 2000, 5000, and 10000 hours to obtain a set of simulation time t data.

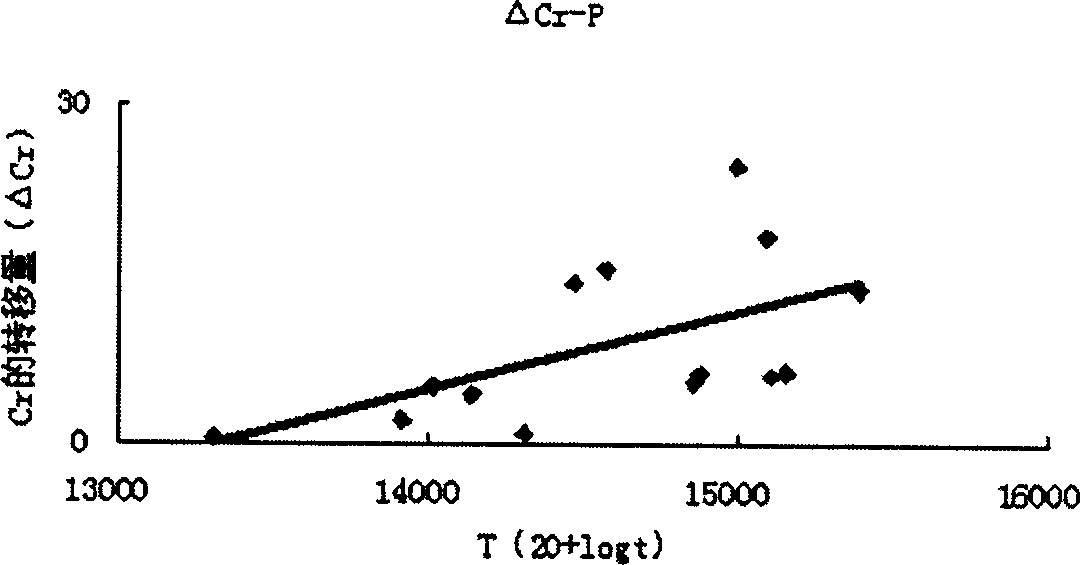

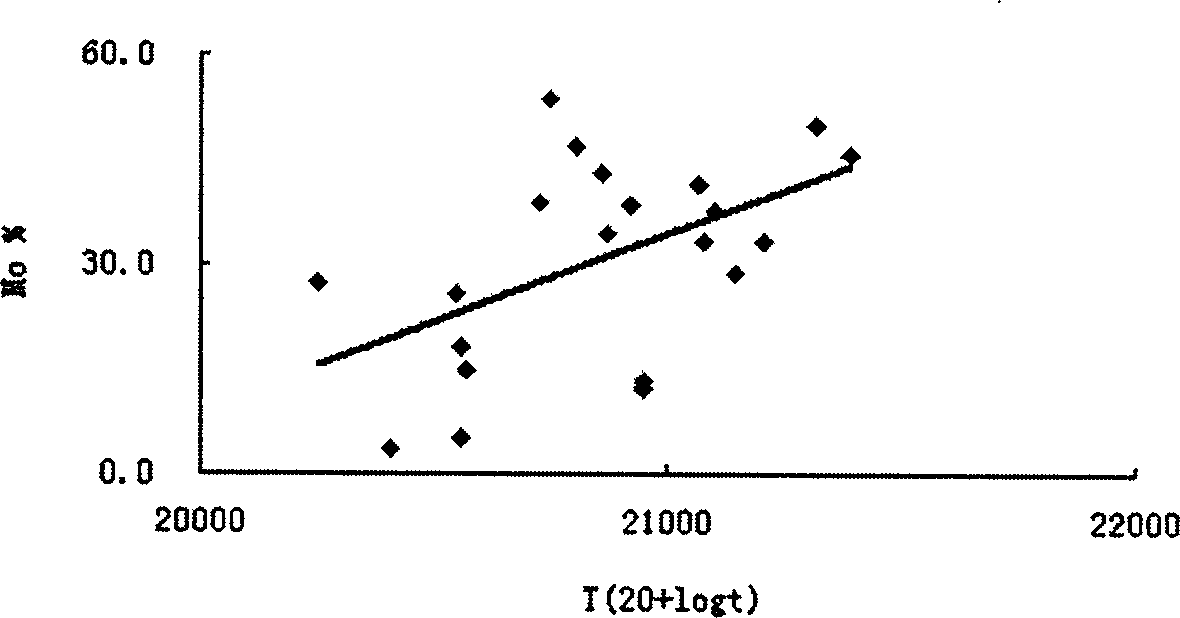

[0015] The carbide phase composition analysis method was used to measure the content composition of carbide alloy elements Cr and Mo before and after each sample was used, and the difference ΔQ was given. Its data are shown in figure 1 , 2 .

[0016] The statistical method of polynomial regression analysis is used to analyze the law between the change of alloy elements in carbide and the test temperature and time. The test conditions are described by the temperature-time parameter LMP, and the statistical relations...

Embodiment 2

[0020] The superheater burst tube failure occurred in the boiler of Nantong Power Plant, and the actual use samples were taken from the high-temperature superheater and high-temperature reheater to analyze and evaluate their service status and residual life. The following table 1 shows the results of carbide phase structure analysis, and table 2 shows the temperature evaluation results (°C) according to the change of Cr content, compared with the results of other evaluation methods such as inner wall scale and hardness. It can be seen that the use of carbide phase composition analysis Compared with the average value of the actual temperature value of the component metal evaluated by this method, the error is relatively smaller than other methods.

[0021]

[0022] assessment method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com