Method for manufacturing pipeline system with connecting part

A technology for piping systems and connecting parts, which is applied in the field of adjusting the length of piping systems, and can solve problems such as adjusting the length of pipes to any value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

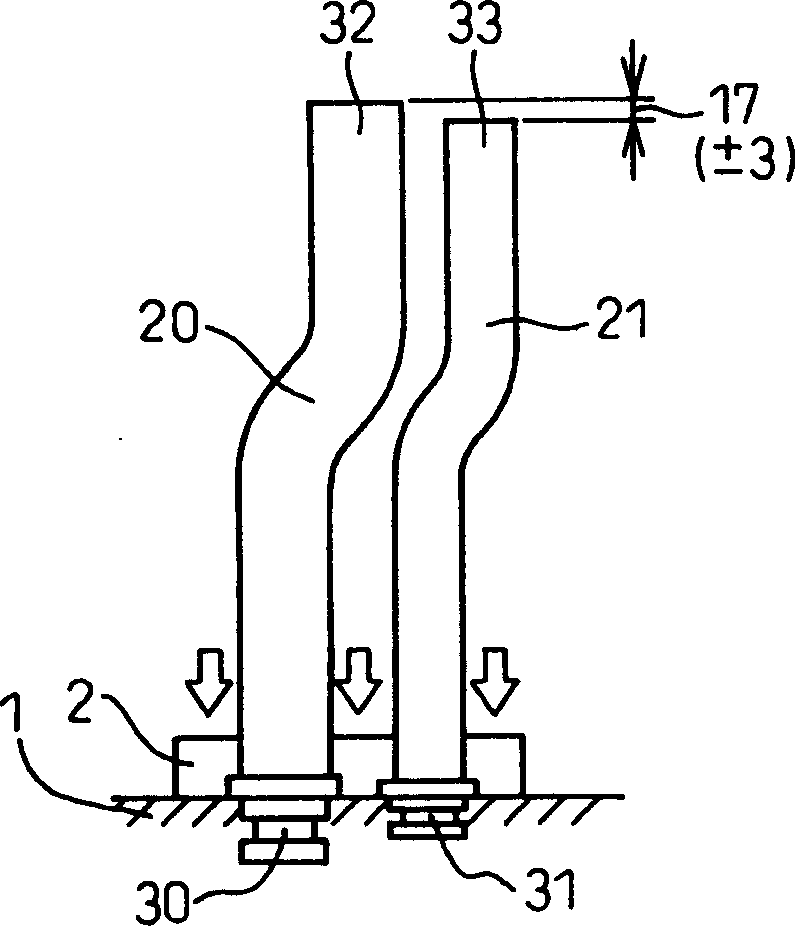

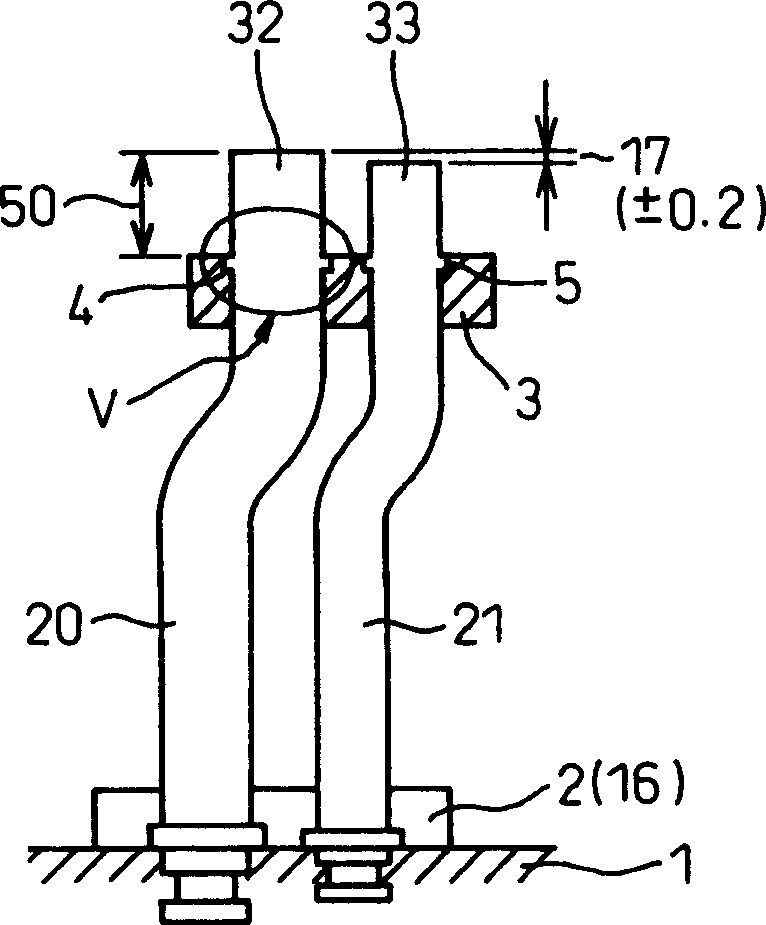

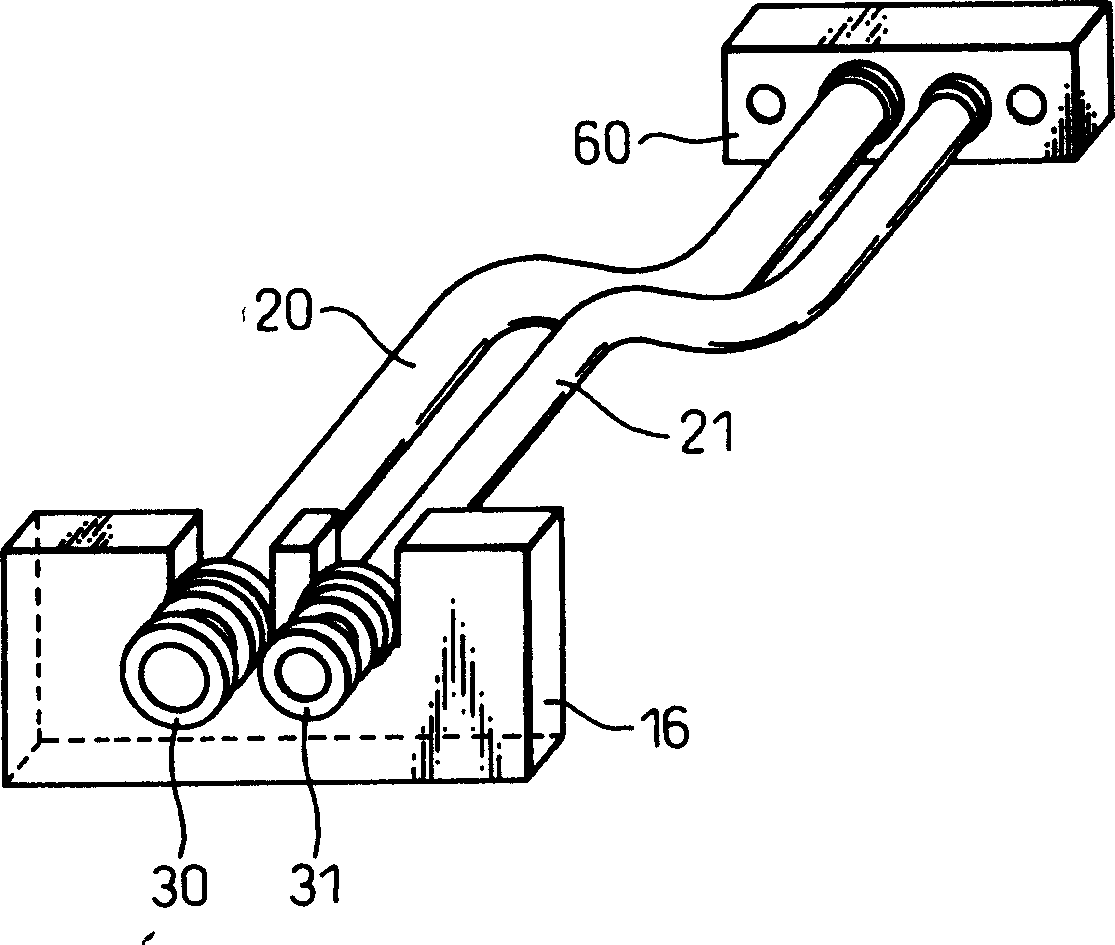

[0041] Hereinafter, several preferred embodiments of the piping system with connecting parts of the present invention will be described in detail with reference to the accompanying drawings. Any of the embodiments shown in the drawings of the present invention relate to a method of manufacturing piping systems connected to front and rear parts of an expansion valve (not shown in the drawings) in a refrigeration cycle of an air-conditioning system for automobiles. Such as image 3 Shown in the appearance of a particular example, the piping system manufactured by the method of the embodiment shown in the figure is for a part of the piping system and includes: a plurality of pipes such as two pipes 21 and 22, one of which is a large diameter pipe, the other pipe is a small diameter pipe, said pipe being bent into a predetermined shape; and two connectors 16, 60 made of thick metal plates, said connectors 16, 60 being formed by caulking Integral with both ends of the tube.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com