Process of finishing slits of surface layer of airplane runway

A surface layer, airport technology, applied in the direction of condensable pavement, roads, floors, etc. paved on site, can solve the problem of shortening the service life of the surface layer 30' of the new runway, shortening the service life of the runway, and expanding the reflection cracks31 Width and other issues, to achieve the effect of multiple waterproof secondary construction joints, easy to popularize and use, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

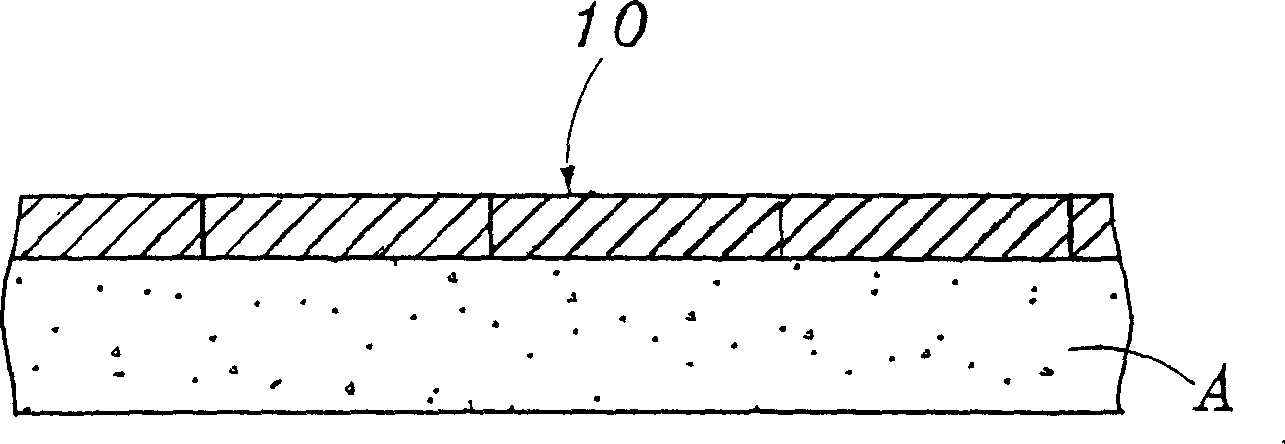

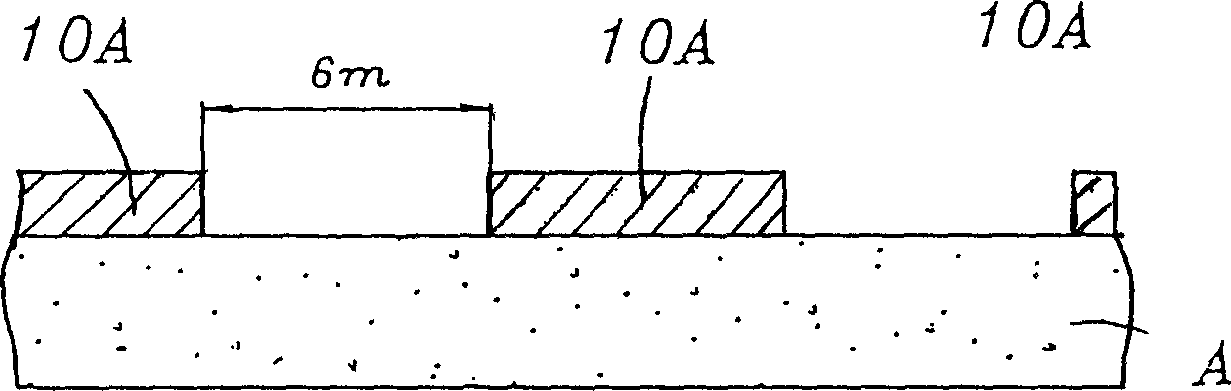

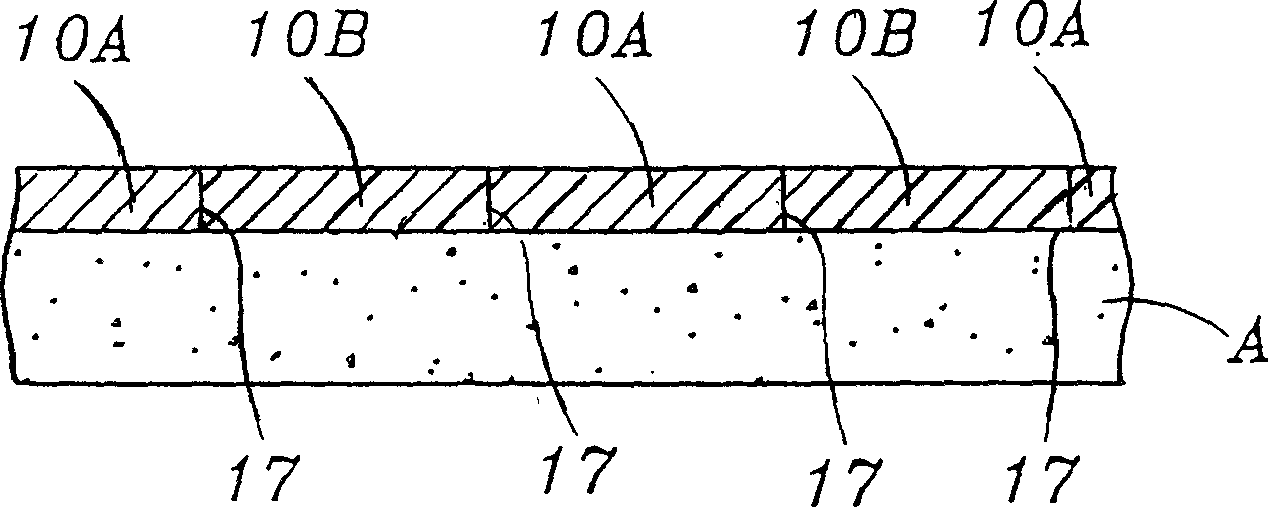

Image

Examples

Embodiment Construction

[0114] First of all, the asphalt synthetic agent used in the present invention is prepared by fusing a straight asphalt and a blown asphalt in an appropriate proportion, and the proportion can be adjusted according to the normal temperature of the construction area. It has fusibility, permeability (melt infiltration into the capillary pores of the base material and small base material), weldability (melt penetration into the surface layer cracks of the base material to be welded and closed), jointability (paste waterproof Adhesive tape strengthens the sealing of cracks and bonding surface layer building materials), and the surface layer has elasticity at room temperature (it can stably join the building materials that are added to the surface layer), water repellency and corrosion resistance.

[0115] The present invention is a kind of construction method to all cracks in the surface layer of the airport runway, and its construction steps are as follows:

[0116] 1. Heat the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com