Membrane separation device composed of multiple groups of membrane module and its operating method

A separation device and membrane module technology, which is applied in the field of membrane separation, can solve the problems of increased water production, high filtration pressure, and low filtration pressure, and achieve the effects of eliminating bypass pipelines, stable water production, and small fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

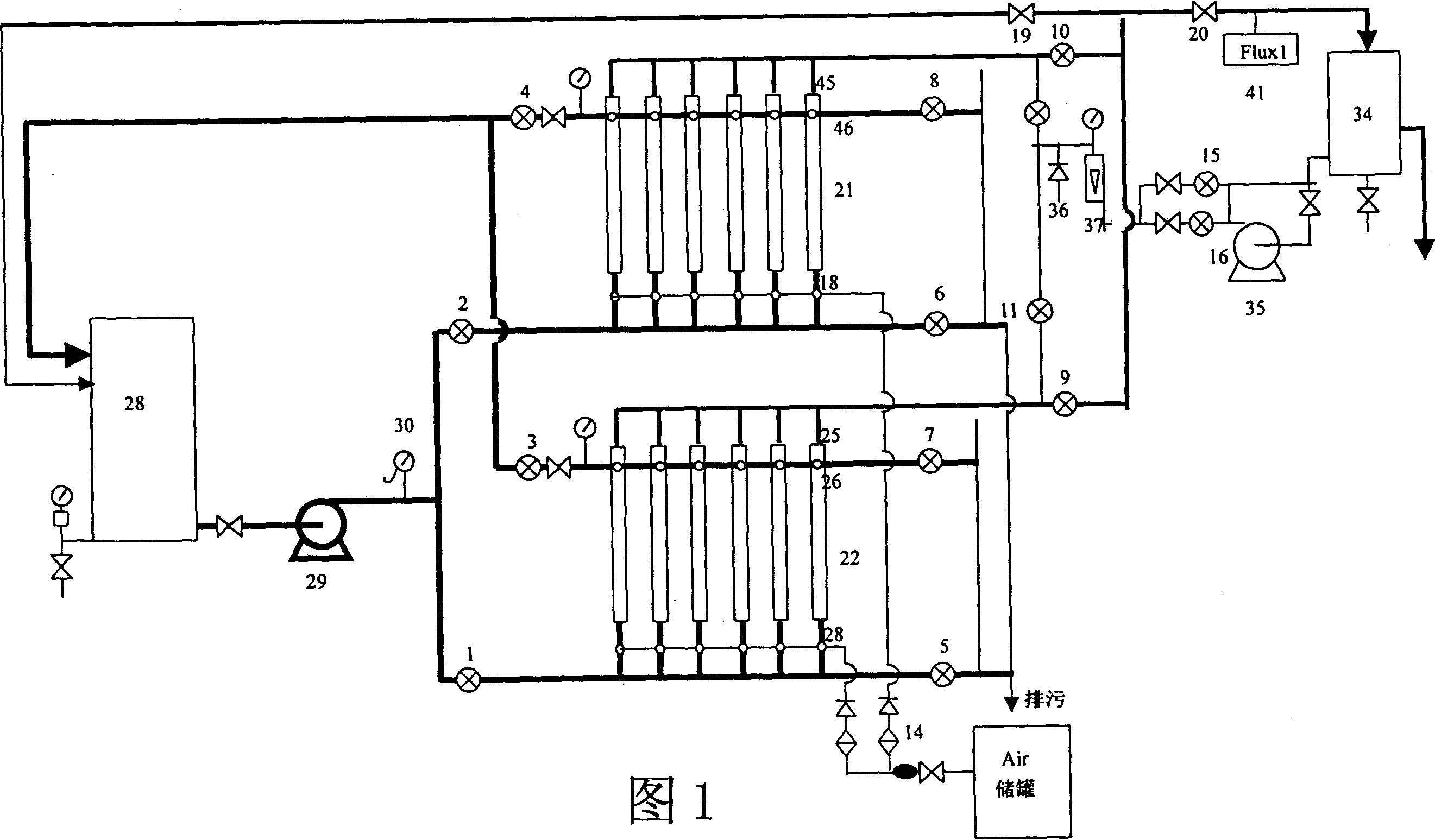

[0035] Adopt the membrane separation device of the present invention as shown in Figure 1, wherein be equipped with 12 6 inch membrane modules, operate according to the following process steps:

[0036] 1) Working status: open automatic valves 1, 2, 3, 4, 9, 10, close automatic valves 5, 6, 7, 8, 11, 12; close solenoid valves 13, 14; start the working pump; adjust the flow sensor Flux1 Specify flow rate; working time is 10-60 minutes.

[0037] 2) The first cleaning state of the first group of membrane components: open valves 2, 4, 7, 10, 11, 13, close valves 1, 3, 5, 6, 8, 9, 12; close solenoid valve 14; adjust flow The sensor Flux1 is (N-1) / N of the original specified flow rate, N is the group number of membrane modules; start the backwash pump; adjust the flow sensor Flux2 to a flow rate of 0.2~6t / h (in each group, the reverse flow rate of each membrane module washing water); start the dosing metering pump, and add oxidant to the system through the dosing port 36; the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com