Equipment for compensating wattless power of electric arc furnace

A technology of power compensation and power compensator, applied in the field of reactive power compensation device of electric arc furnace, can solve the problems of high cost, difficult to implement, small compensation effect, etc., and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

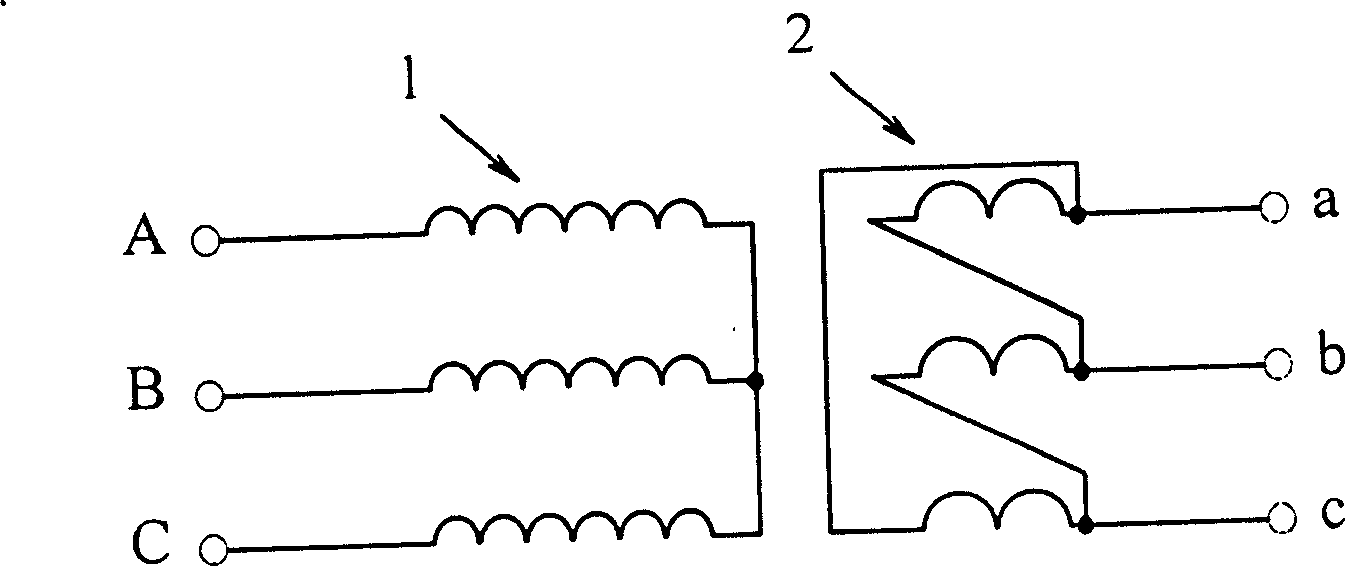

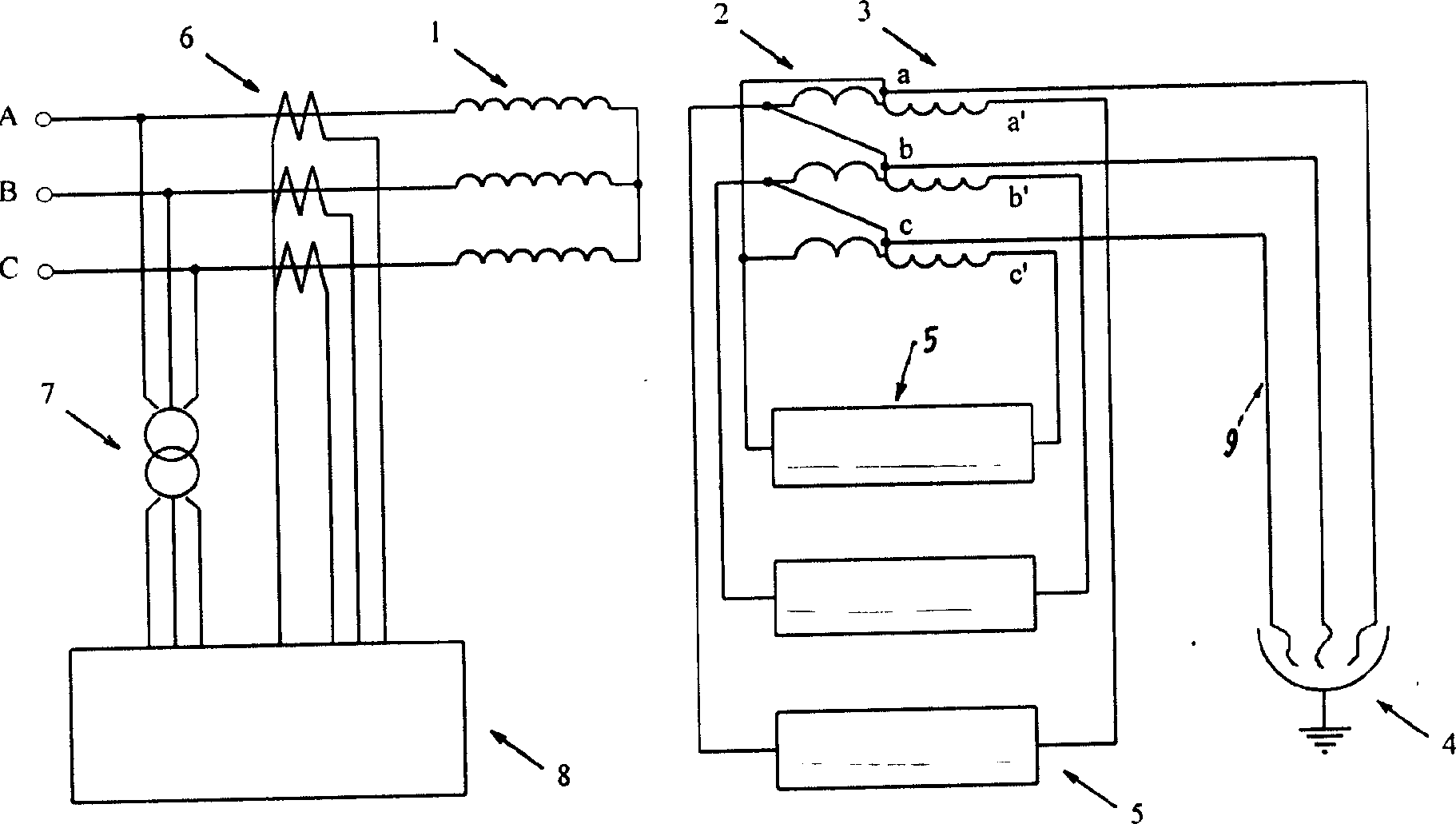

[0022] Embodiment 1. Reactive power compensation device for electric arc furnace

[0023] The electric arc furnace reactive power compensation device of this example, its specific structure is given by image 3 Shown in this example is a phase reactive power compensation device for an electric arc furnace 4, the device includes a transformer high voltage side primary winding 1, a low voltage side secondary winding 2, an electric arc furnace reactive power compensator 5, The current transformer 6, the voltage transformer 7 and the reactive power measuring and controlling device 8, especially including the secondary autocoupling winding 3 on the low-voltage side of the electric arc furnace transformer, are jointly connected and assembled. The secondary auto-coupling winding 3 on the low-voltage side of the electric arc furnace transformer is composed of longitudinally added partial windings on the primary secondary winding 2 on the low-voltage side of the electric arc furnace tr...

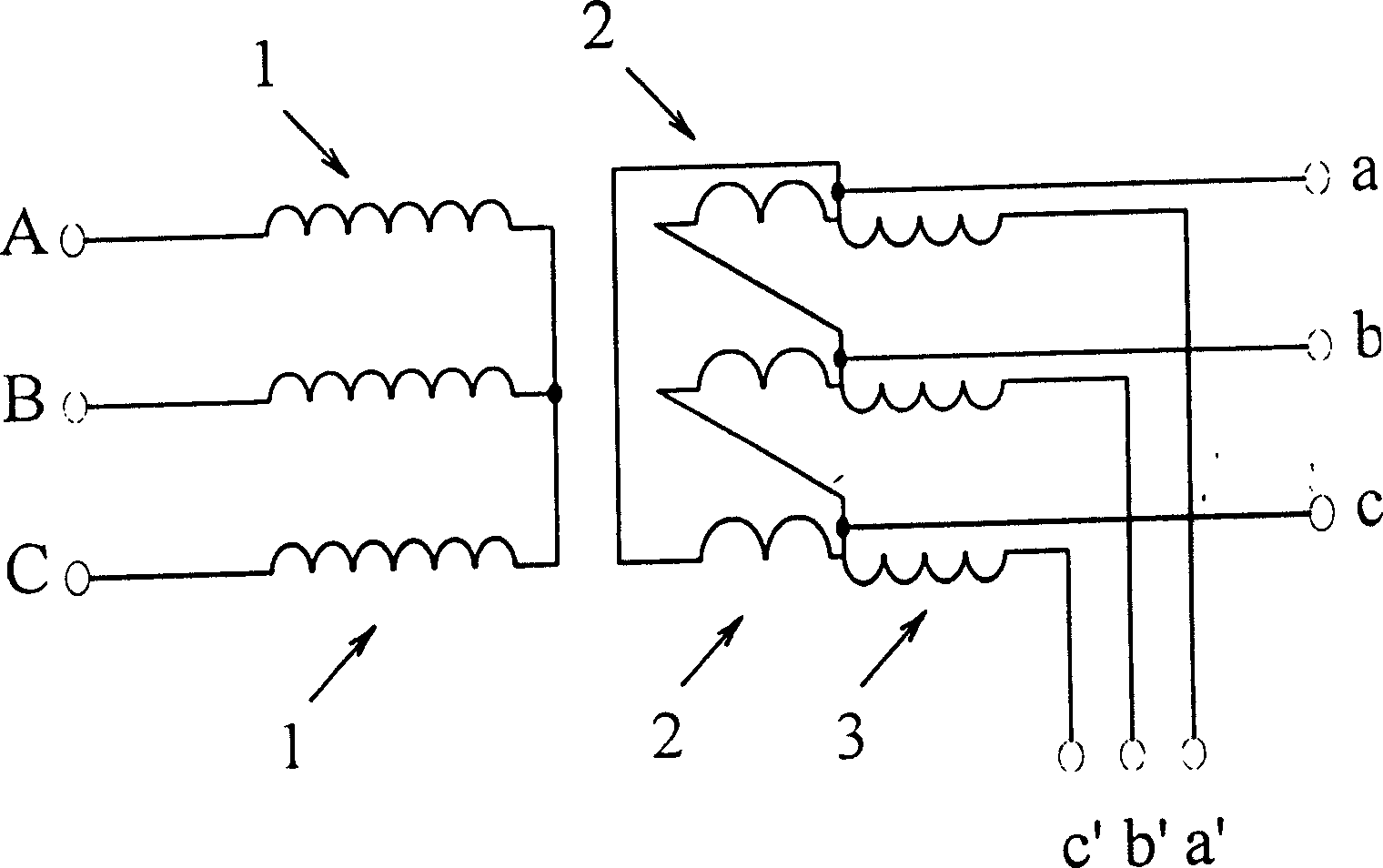

Embodiment 2

[0024] The electric arc furnace reactive power compensation device of this example, its specific structure is given by Figure 4It shows that the reactive power compensator 5 on the 4 phases of the electric arc furnace in this example can be connected in a Δ type, and the three terminals of Δ are respectively connected to the outlet terminals a' and b of the secondary autocoupling winding 3 on the low voltage side of the electric arc furnace transformer ', c' on. All the other undescribed are the same as those described in Embodiment 1, and will not be repeated

Embodiment 3

[0025] Embodiment 3. Reactive power compensation device for electric arc furnace

[0026] The specific structure of the reactive power compensation device of the electric arc furnace in this example is shown in Figure 5, and the reactive power compensator 5 on the 4 phases of the electric arc furnace in this example can be connected as a Y 0 Type, Y 0 The three terminals of the electric arc furnace transformer are respectively connected to the outlet terminals a', b' and c' of the secondary autocoupling winding 3 on the low voltage side of the electric arc furnace transformer, Y 0 The zero point is grounded. The rest are the same as those described in Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com