Combined technologic process for manufacturing petroleum residue

A combined process and residual oil technology, which is applied in the field of residual oil processing combined process, can solve the problems of increasing costs and expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

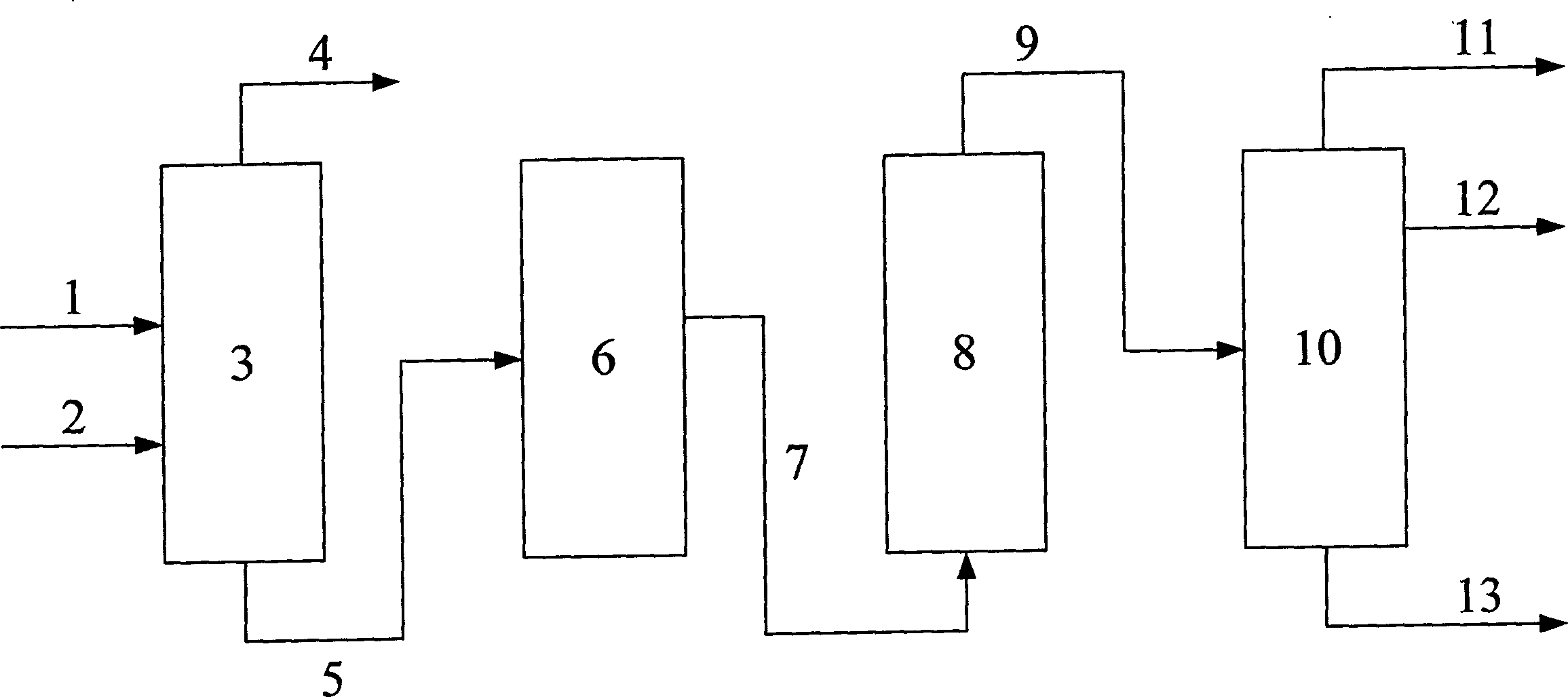

Method used

Image

Examples

Embodiment 1

[0031] The raw material that present embodiment adopts is vacuum residue A, and its property sees 1, and table 2 is the deoiled bitumen property that vacuum residue A obtains after propane deasphalting, and deasphalting oil yield is 50% (weight), It can be seen from Table 2 that the kinematic viscosity of deoiled bitumen at 100°C is 5 times that of vacuum residue A, and the crackable component of saturated hydrocarbon is only 15.40% and the colloid is as high as nearly 50%.

[0032] Trials were carried out on a medium-sized solvent deasphalting unit with a RIPP capacity of 10 kg / h and a visbreaker at 5 kg / h.

[0033] Table 3 shows the visbreaking process conditions, material balance and visbreaking residue properties of the mixture. It can be seen from Table 3 that the viscosity of deoiled asphalt (at 100°C) has dropped to 188.5mm 2 / s, the effect of reducing viscosity is obvious.

Embodiment 2

[0035] The raw material used in this embodiment is vacuum residue B, whose properties are shown in 1. Table 2 shows the properties of deoiled asphalt obtained after deasphalting vacuum residue B with butane. The yield of deasphalted oil is 63% (weight). , as can be seen from Table 2, the kinematic viscosity of deoiled asphalt at 100 ° C is about 10 times higher than that of vacuum residue B, saturated hydrocarbons as crackable components are only 5.2%, and colloids are as high as 52%.

[0036] The tests were carried out on a medium-sized solvent deasphalting unit with a RIPP capacity of 10 kg / h and a mild thermal cracking unit at 5 kg / h.

[0037] Table 3 shows the visbreaking process conditions, material balance and visbreaking residue properties of the mixture. It can be seen from Table 3 that the viscosity of deoiled asphalt (at 100°C) has dropped to 347.9mm 2 / s, the effect of reducing viscosity is obvious.

[0038] Example 1

[0039] Example 1

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com