Application of fluorinated silicone rubber to prepare synthetic insulator

A technology of synthetic insulators and fluorosilicone rubber, which is applied in the direction of rubber insulators, organic insulators, insulators, etc., can solve the problems of lack of resistance to tracking and other problems, and achieve good anti-pollution flashover performance, reduce labor intensity, and high operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

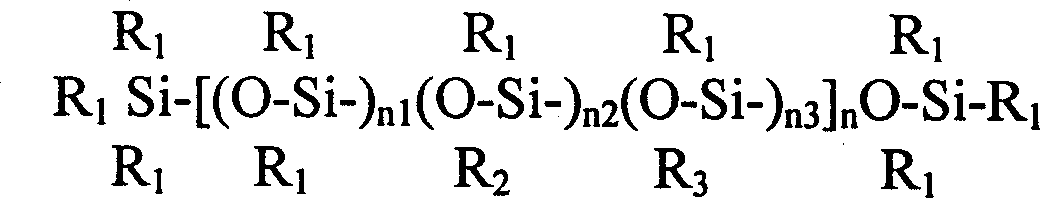

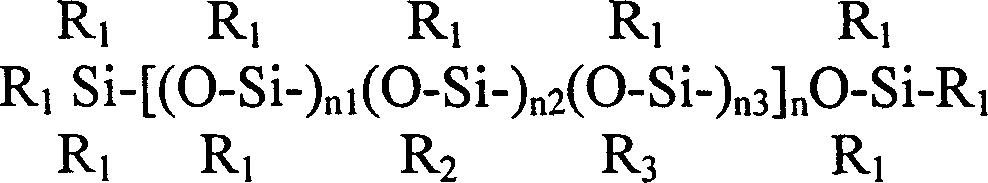

Image

Examples

Embodiment 1

[0013] 100 parts of fluorosilicone rubber containing 80% fluorine-containing silicone linking units, 10 parts of fumed silica, 30 parts of aluminum hydroxide, 3 parts of processing aids, in a container with a vacuum degree of -0.095MPa and a temperature of 180°C Mixed for 2 hours and stored overnight. Add 0.4 parts of vulcanizing agent, injection molding at 160°C. After testing, the 500kv fluorosilicone rubber insulators vulcanized at 180°C for 8 hours, the contact angle of water droplets on the surface is 104°, and there is no change after soaking in hydrochloric acid with a temperature of 50°C and a concentration of 5% for 20 days.

Embodiment 2

[0015] 100 parts of fluorosilicone rubber containing 98% fluorine-containing silicone linking units, 10 parts of fumed silica, 30 parts of aluminum hydroxide, 3 parts of processing aids, in a container with a vacuum degree of -0.095MPa and a temperature of 180°C Mixed for 2 hours and stored overnight. Add 0.4 parts of vulcanizing agent, injection molding at 160°C. After testing, the 330kv fluorosilicone rubber insulators vulcanized at 180°C for 8 hours, the contact angle of water droplets on the surface is 106°, and there is no change in 50°C hydrochloric acid with a temperature of 50°C and a concentration of 5% for 20 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com