Scanning probe microscope

A technology of scanning probe and microscope, which is applied in the field of scanning probe microscope, can solve the problems of image instability, low resolution, and limited application range, and achieve the effect of reducing image distortion and preventing scratching of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

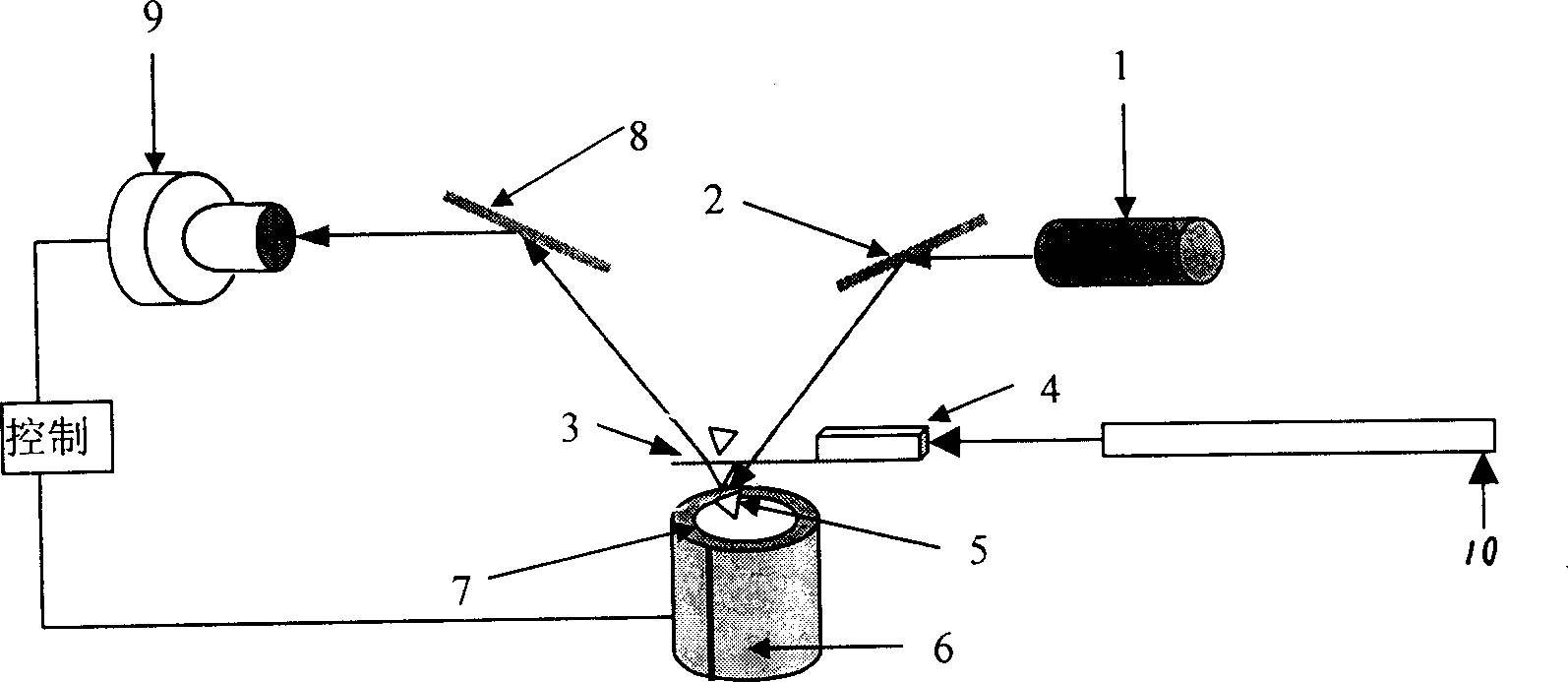

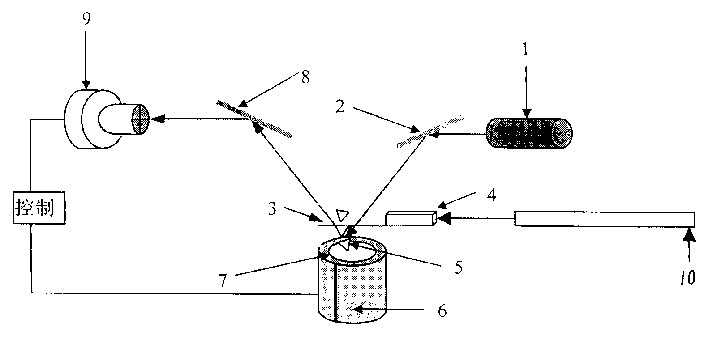

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

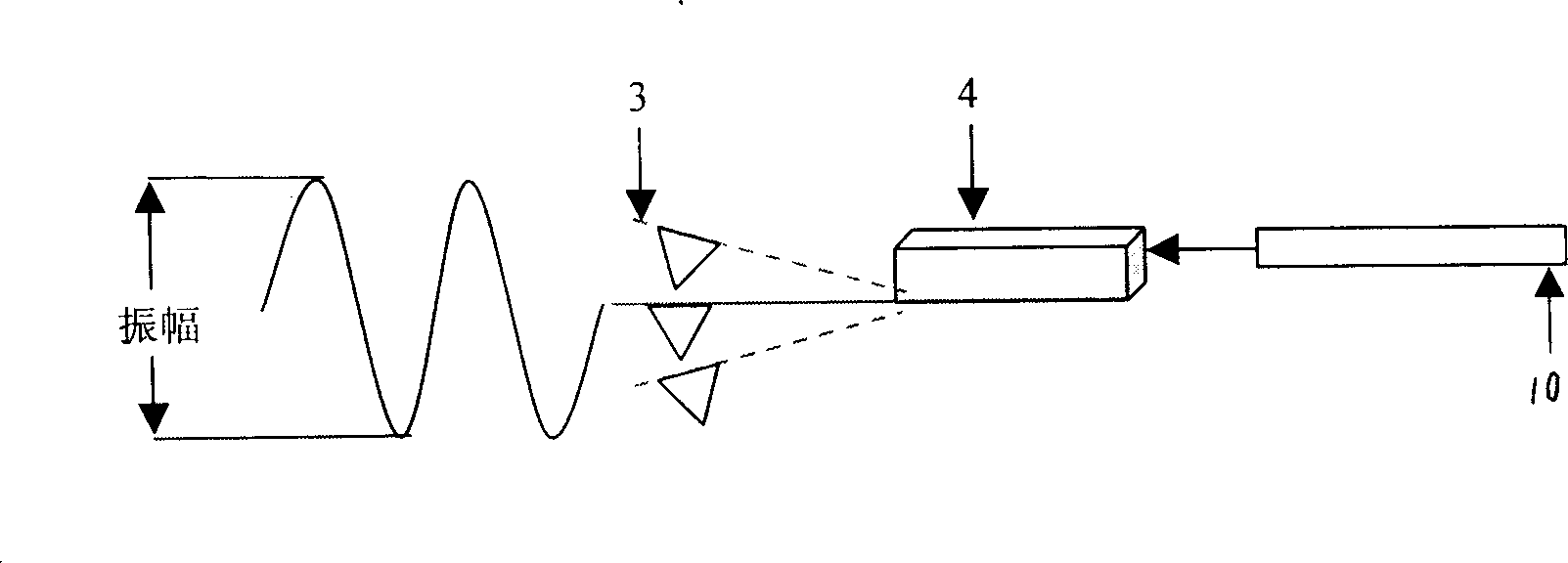

[0023] Such as figure 1 and figure 2 As shown, the scanning probe microscope of the present invention includes a laser tube 1 , a mirror 2 , a piezoelectric ceramic crystal 4 , a microcantilever 3 , a needle tip 5 , a scanning tube 6 , a mirror 8 , a spot position detector 9 , and a sample 7 . The piezoelectric ceramic crystal 4 controlled by the oscillation frequency controller 10 drives the microcantilever 3 to oscillate with a certain oscillation frequency and amplitude. When the vibration frequency of the needle tip is the same as the natural frequency of the needle tip, a resonant peak will appear, and the amplitude at this time is converted into an electrical signal by the control circuit, and the microcantilever 3 with the needle tip 5 is made to have this amplitude under the control of the control system. Oscillate on the surface of sample 7. As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com