Isolated copper wire cable with copper armoured under 3KV voltage rating and manufacture thereof

A mineral insulated cable, rated voltage technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of few applicable occasions, poor cable insulation performance, low withstand voltage level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

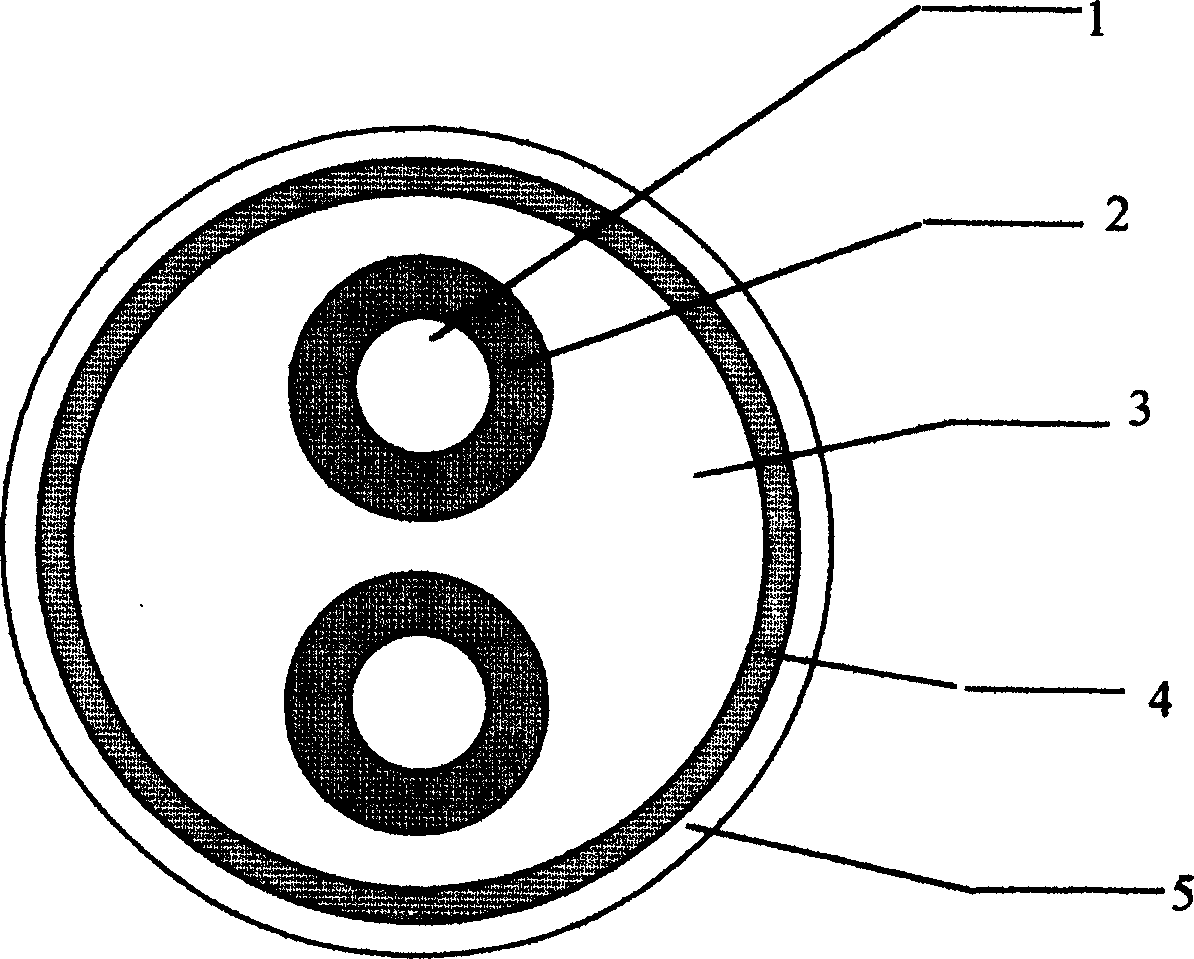

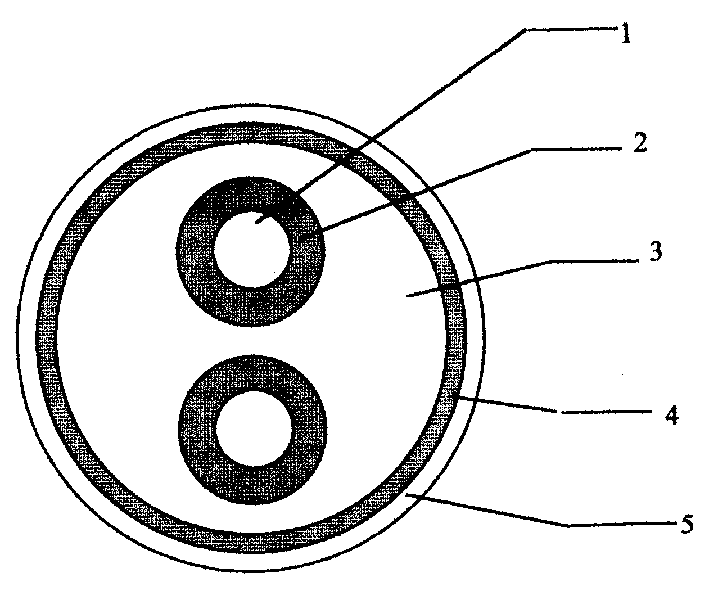

[0011] In the embodiment shown in the figure, the conductor 1 is drawn from a solid copper rod code-named T2, and a conductor covering layer 2 is wrapped around the surface of the conductor 1 flatly and obediently. The conductor covering layer 2 is formed by overlapping and wrapping mica tapes. Conductor 1 and conductor covering layer 2 form a conductor core, and a seamless phosphorus deoxidized copper tube code-named TP1 or TP2 or TU2 is used as a copper sheath on the conductor core coat 4 In the copper sheath 4, tightly compacted magnesium oxide powder is used as the insulating layer 3 to separate from the conductor core. A layer of thermoplastic material can also be arranged outside the copper sheath 4 to form the outer sheath 5. Due to the conductor covering layer 2 The material, that is, the overlapping and wrapping mica tape has good insulation performance and high voltage level, which effectively changes the withstand voltage performance of the cable. Compared with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com