Performance-improved white organic luminescent device

A device and organic technology, applied in the field of organic light-emitting OLED devices, can solve problems such as changes in the color of emitted light and difficult process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

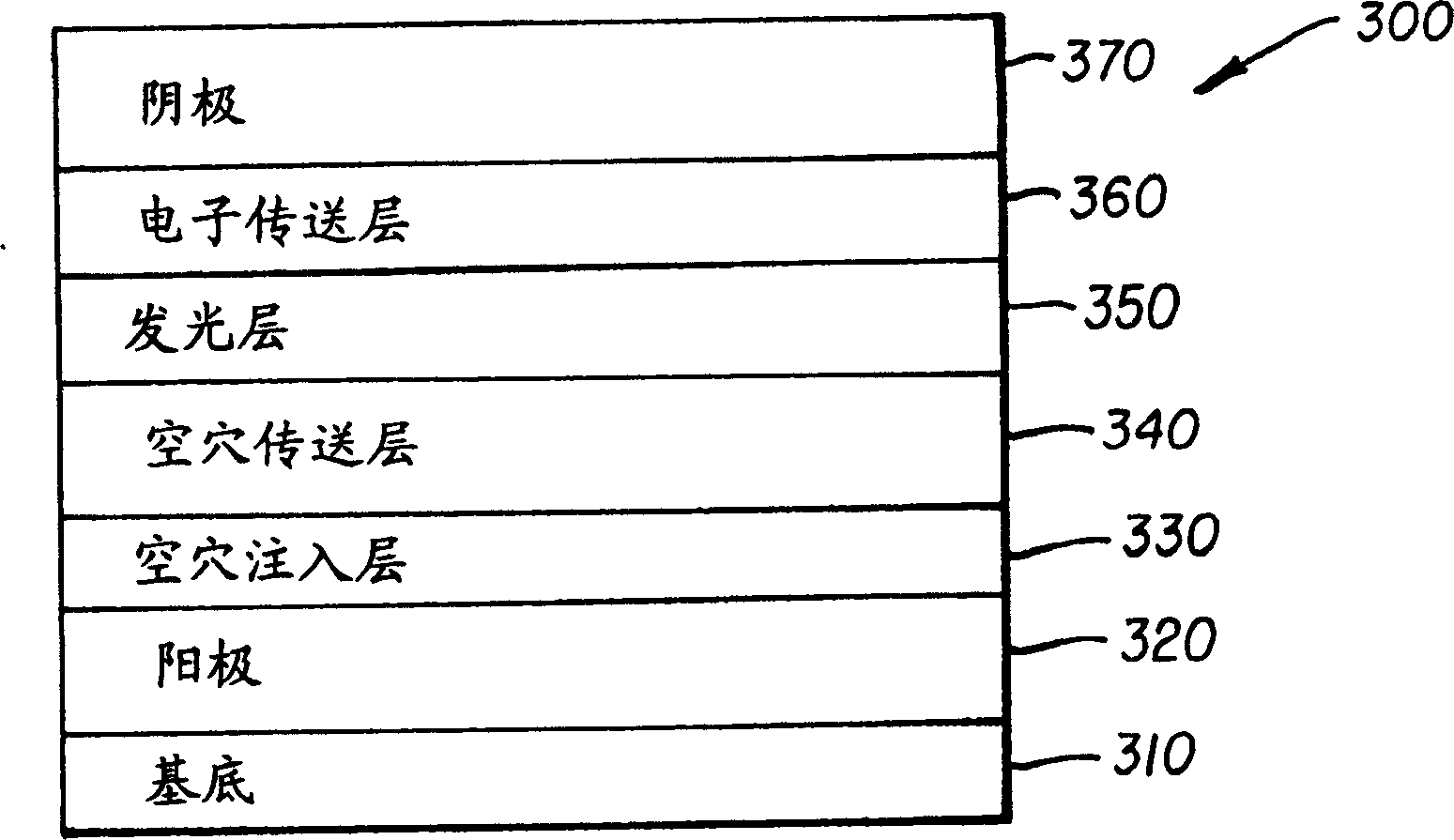

[0191] The device of Example 1 was prepared by sequentially depositing a 150 nm NPB hole transport layer (HTL), a 20 nm blue light emitting layer (LEL) of a TBADN matrix containing 2% TBP blue dopant, a 37.5 nm Alq electron transport layer (ETL), and then 0.5nm LiF and 200nm Al as part of the cathode. The above sequence completes the deposition of the OLED device.

[0192] Then the OLED device was sealed and packaged in a nitrogen-filled dry glove box to isolate the surrounding environment. The ITO patterned substrates used to fabricate OLED devices included several experimental patterns. Each device was tested for its volt-ampere characteristic curve and electroluminescence yield.

[0193] according to image 3 Devices of Examples 2-6 were prepared with the structure of OLED 300 shown in . A 150 nm thick NPB hole transport layer was doped with varying amounts of rubrene at a concentration of 1-5%. The device of Example 1 was found to have emission in the blue region of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com