Method for preparing Ti-MWW molecular sieve film

A technology of molecular sieves and supports, which is applied to the preparation of molecular sieve catalysts, molecular sieves and base exchange compounds, oximes, etc., can solve the problems of high production costs, large demand for titanium-silicon molecular sieves, difficulties in separation and recovery, etc., and achieve simple operation, membrane Preparation of highly reproducible, good catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

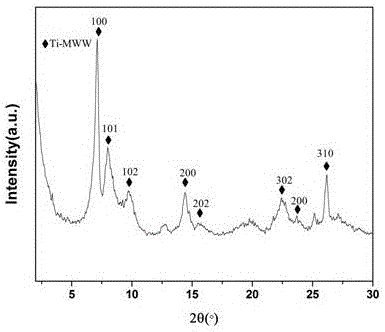

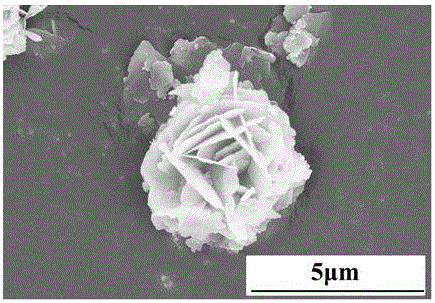

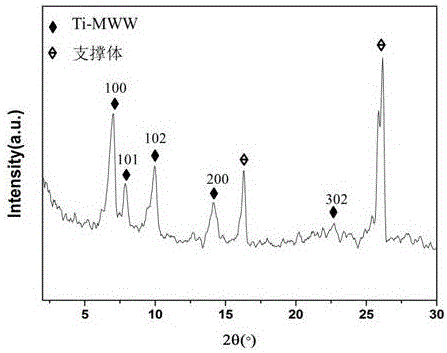

[0028]Preparation of Ti-MWW molecular sieve crystal seeds: Mix tetraethylorthosilicate and template agent hexamethyleneimine (HMI) into a pp bottle of water and hydrolyze in an ice-water bath at 0ºC, while tetrabutyl titanate, boric acid Add water and water to hydrolyze in an ice-water bath at 0ºC. After the titanium source and silicon source are completely hydrolyzed, mix them to obtain a molar ratio of 1.0 SiO 2 : 0.03TiO 2 : 0.67B 2 o 3 : 1.4HMI: 19H 2 The light yellow synthetic sol of O, and then transfer the synthetic sol to a stainless steel reactor with a polytetrafluoroethylene liner and crystallize it in an oven at 170 ºC for 8 days. The crystallized material is washed in boiling water until neutral and dried Ti-MWW molecular sieve precursor with 2 M HNO 3 The solution was refluxed at 100ºC to treat the dried molecular sieve precursor, wherein the mass ratio of the molecular sieve precursor to the volume of the nitric acid solution was 1:20, the acid treatment tim...

Embodiment 2

[0031] The synthesis ratio of the Ti-MWW molecular sieve membrane is the same as that of the preparation step Example 1, except that the secondary hydrothermal time is extended to 6 d, Figure 5 SEM photographs of the surface and cross-section of the prepared Ti-MWW molecular sieve membrane. The electron microscope photographs show that the surface of the support is covered by dense flaky Ti-MWW molecular sieve crystals, and the crystals on the upper layer grow perpendicular to the direction of the support. The thickness of the crystal layer is about 4 μm, the crystals in the lower layer grow parallel to the direction of the support, and the thickness of the crystal layer is about 7 μm.

Embodiment 3

[0033] The synthesis ratio of the Ti-MWW molecular sieve membrane is the same as that of the preparation step Example 1, except that the secondary hydrothermal time is extended to 8 d, Figure 6 SEM photos of the surface and cross-section of the prepared Ti-MWW molecular sieve membrane. The SEM photos show that the surface of the support is covered by two layers of dense sheet-like Ti-MWW molecular sieve crystals. The crystals on the upper layer grow perpendicular to the direction of the support. The thickness of the crystal layer is about The thickness of the crystal layer is 3 μm; the crystals in the lower layer grow parallel to the direction of the support, and the thickness of the crystal layer is 9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com