Method for preparing Ti-MWW molecular sieve membrane by double-template method

A technology of molecular sieves and supports, applied in the direction of molecular sieve catalysts, catalyst activation/preparation, molecular sieves and base exchange compounds, etc., can solve the problems of affecting catalytic activity and increasing the electronegativity of the skeleton, and achieve simple operation and solve the difficulty of separation and recovery , Solve the effect of low reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

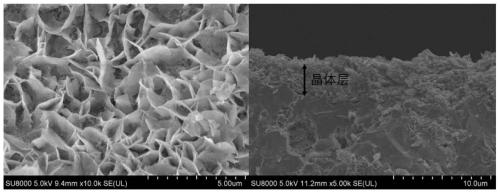

[0027] Follow the steps below to prepare Ti-MWW molecular sieve membranes:

[0028] (1) Add K to TMAdaOH aqueous solution 2 CO 3 , after stirring evenly, add HMI and tetrabutyl titanate, stir at room temperature for 30 minutes until clear, then add HS-40 and stir evenly, and age for 1 hour to obtain a molar ratio of 1SiO 2 :0.03TiO 2 :0.26TMAdaOH:0.3HMI:0.07K 2 O:60H 2 Synthetic gel of O;

[0029] (2) The pure phase flake Ti-MWW molecular sieve prepared by the method in the literature (J.PhyS.Chem.B, 105(2001) 289; J.Catal., 201(2001) 24) is used as a seed crystal and coated on 10cm On the outer surface of the tubular mullite support body, dry in an oven at 80°C for 3 hours;

[0030] (3) Then transfer the prepared synthetic gel and the support with pre-coated seed crystals to a titanium kettle, and the reactor was crystallized at 170°C for 6 days, and the crystallized samples were washed in boiling water. to neutral and dry at 80°C for 6 hours;

[0031] (4) Put the dri...

Embodiment 2

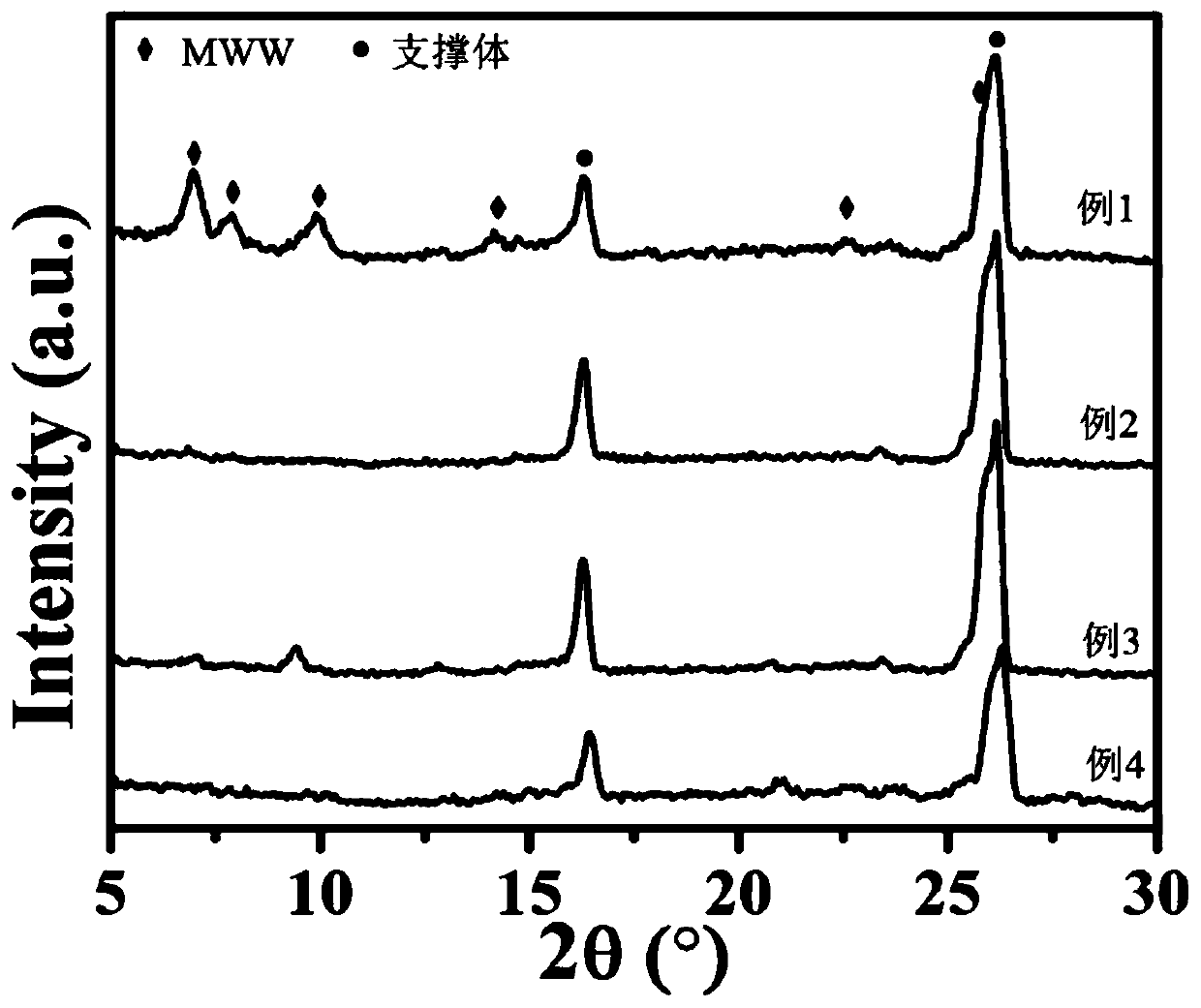

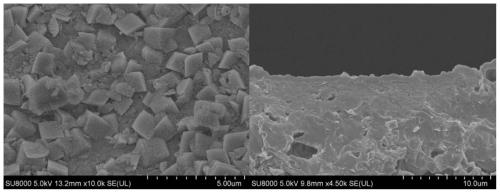

[0034] The molar proportioning in embodiment 1 is adjusted to 1SiO 2 :0.03TiO 2 :0.26TMAdaOH:0.3HMI:60H 2 O, do not join K 2 CO 3 , other synthesis conditions are consistent with Example 1. Since no film layer was formed without the addition of alkali metal, no catalytic performance was exhibited during the catalytic process.

Embodiment 3

[0036] The molar proportioning in embodiment 1 is adjusted to 1SiO 2 :0.03TiO 2 :0.56TMAdaOH:0.07K 2 O:60H 2 O, without adding HMI, other synthesis conditions are consistent with Example 1. Since the film growth is not dense, it does not exhibit catalytic performance during the catalytic process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com