High-performance polyimide hollow fiber membrane and preparation method and application thereof

A polyimide and fiber membrane technology, which is applied in the field of preparation of polyimide hollow fiber gas separation membranes, can solve the problems of fragility and breakage of membrane filaments, decrease in molecular weight, and difficulty in preparing membrane-forming components, so as to improve the resistance to Solvent properties and mechanical strength, the effect of mechanical strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

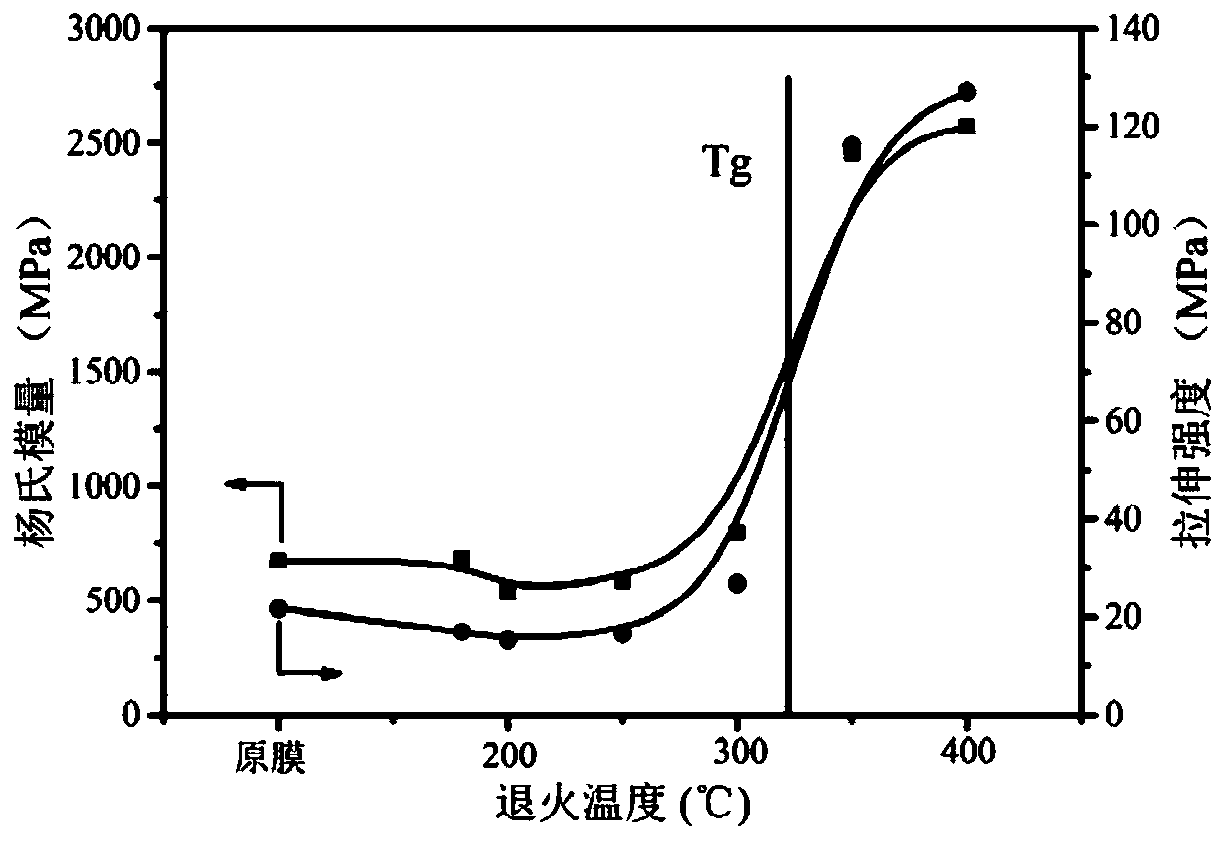

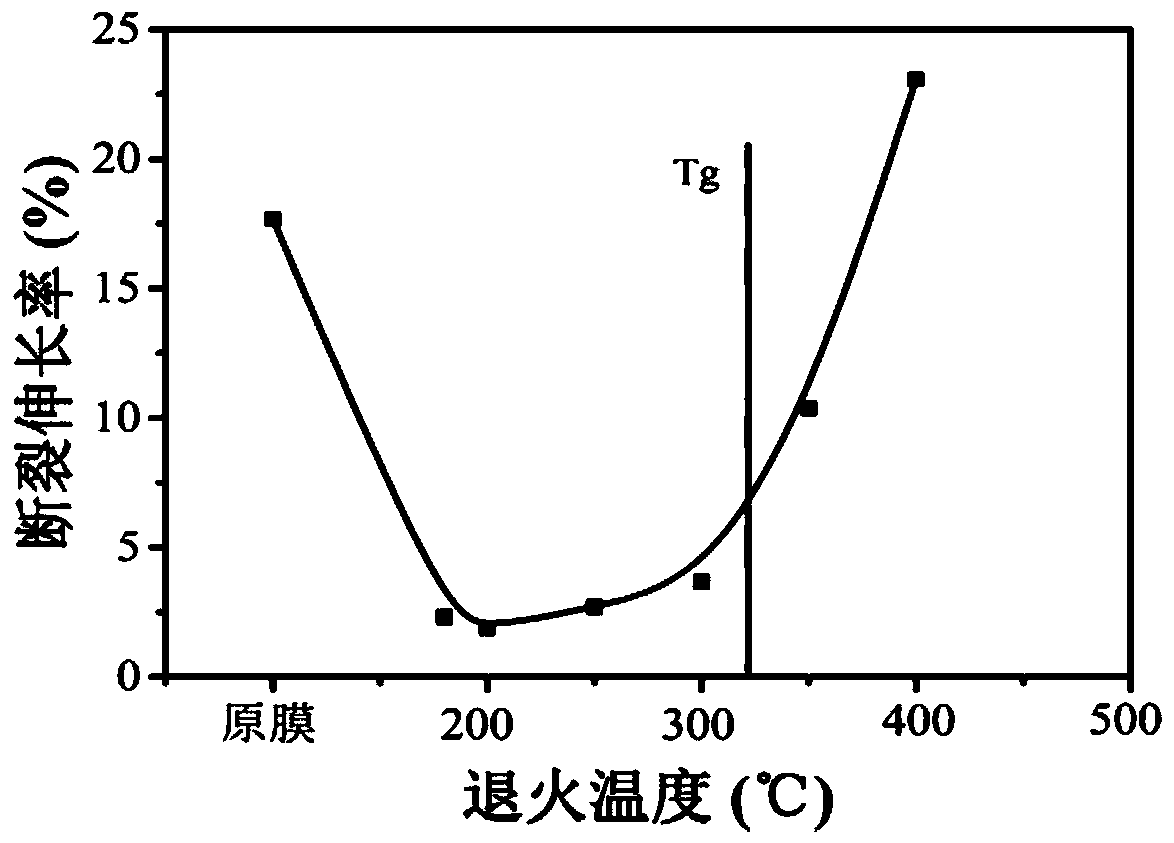

[0046] Annealing the hollow fiber membrane filaments prepared in Example 1. The annealing procedure is: from room temperature to 110 degrees at a heating rate of 10 °C / min, staying at 110 °C for 1 hour, and at a heating rate of 5 °C / min from 110 °C to 110 °C. °C to 250 °C, at a rate of 2 °C / min from 250 to 300, and stay for 1 hour. Tensile strength, Young's modulus and elongation at break are shown in Table 1, figure 1 with figure 2 The value corresponding to 300℃ in

Embodiment 2

[0048] Annealing the hollow fiber membrane filaments prepared in Example 1. The annealing procedure is: from room temperature to 110 degrees at a heating rate of 10 °C / min, staying at 110 °C for 1 hour, and at a heating rate of 5 °C / min from 110 °C to 110 °C. °C to 250 °C, with a heating rate of 2 °C / min from 250 to 350, and stay for 1 hour. Tensile strength, Young's modulus and elongation at break are shown in Table 1, figure 1 with figure 2 The value corresponding to 350℃ in

Embodiment 3

[0050] Annealing the hollow fiber membrane filaments prepared in Example 1. The annealing procedure is: from room temperature to 110 degrees at a heating rate of 10 °C / min, staying at 110 °C for 1 hour, and at a heating rate of 5 °C / min from 110 °C to 110 °C. °C to 250 °C, with a heating rate of 2 °C / min from 250 to 400, and stay for 1 hour. Tensile strength, Young's modulus and elongation at break are shown in Table 1, figure 1 with figure 2 The value corresponding to 400℃ in

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com