Dressing container with several covers

A container and bottom box technology, applied in the field of cosmetic boxes, can solve problems such as wasting manpower, high cost, and economic benefit discounts, and achieve the effects of saving labor, reducing loss, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

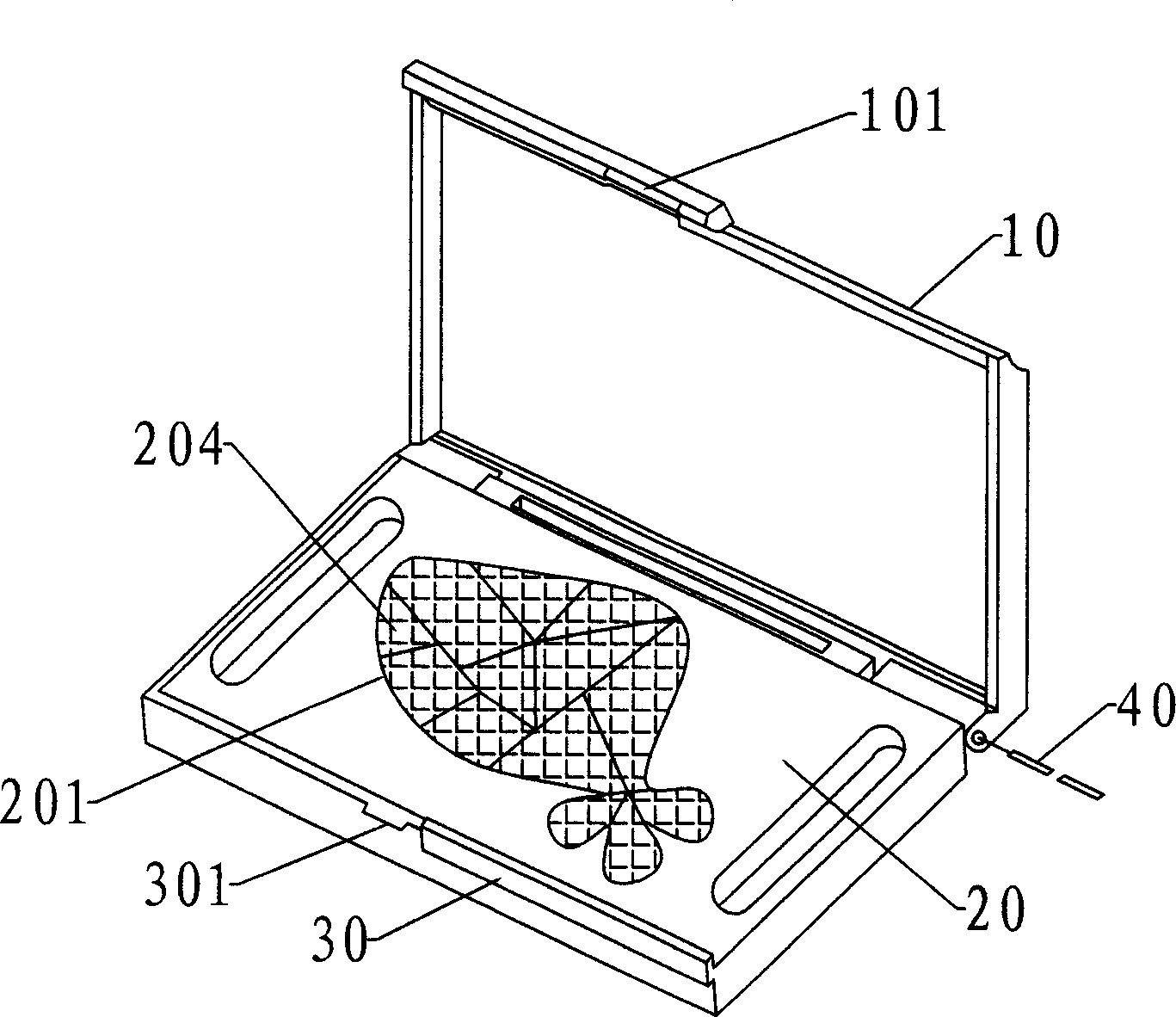

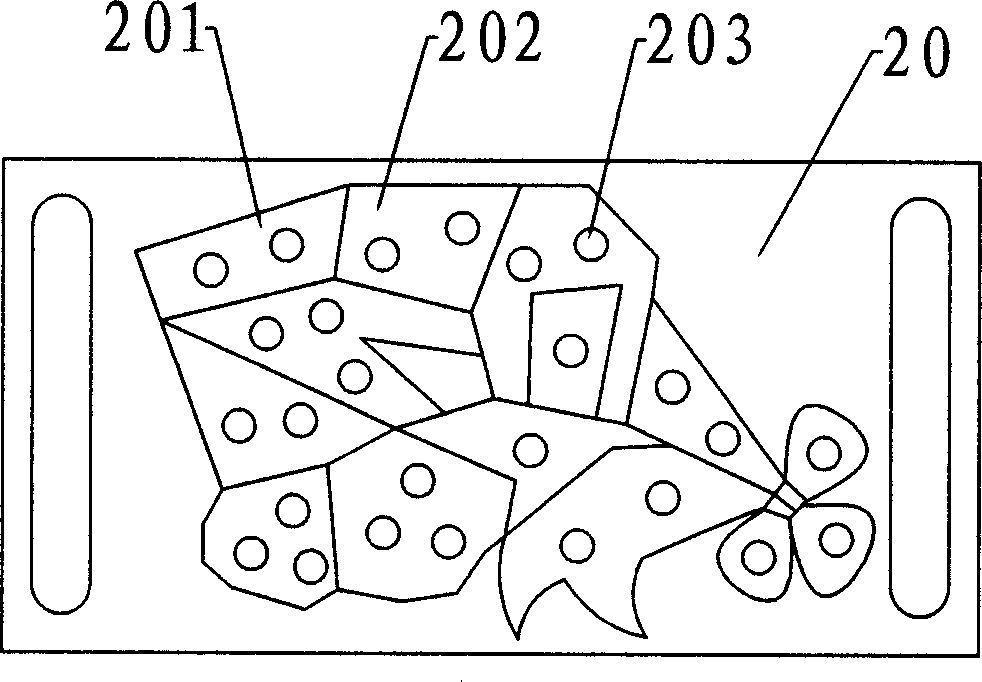

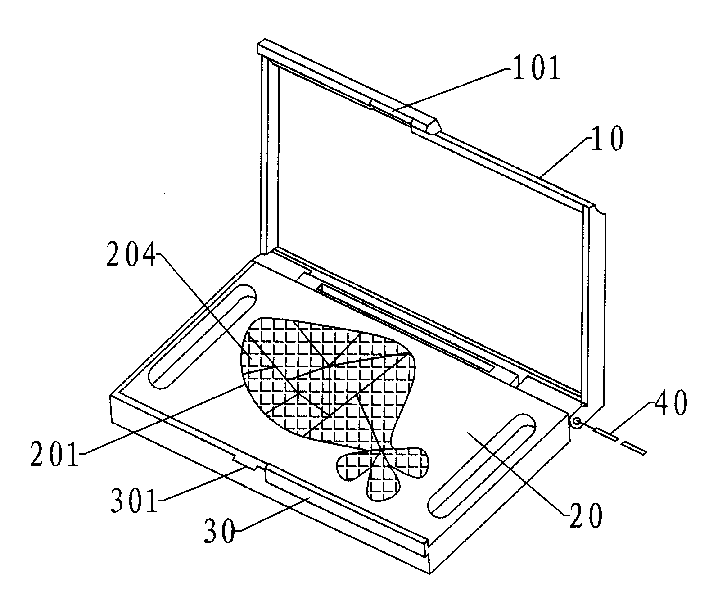

[0008] As shown in the figure, it includes an upper cover 10, a color tray 20 that can be filled with coloring material, and a bottom box 30 that can hold the color tray. The upper cover 10 and the bottom box 30 are pivotally connected through a pin 40 , so that the upper cover 10 can be opened and closed freely, and the front end of the bottom box 30 is provided with a protruding piece 301 which can provide a pair of grooves on the inner side of the upper cover 10 to engage with. The above-mentioned color wheel 20 is placed on the bottom box 30, wherein the color wheel 20 is divided into a plurality of color material storage areas 202 by partitions 201, and the partitions 201 are arranged in a curved shape of a radial swirl to increase Its natural form is aesthetically pleasing, and each color material storage area 202 is provided with a filling port 203 , and the filling port 203 runs through the bottom of the color plate 20 , and the color material can be directly filled thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com