Contact type object position and gesture measurer

A measuring device, a technology for pose measurement, applied in electromagnetic measuring device, electric/magnetic profile/curvature measurement, mechanical counter/curvature measurement, etc. Detection speed, avoidance of uncertainty and error, the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

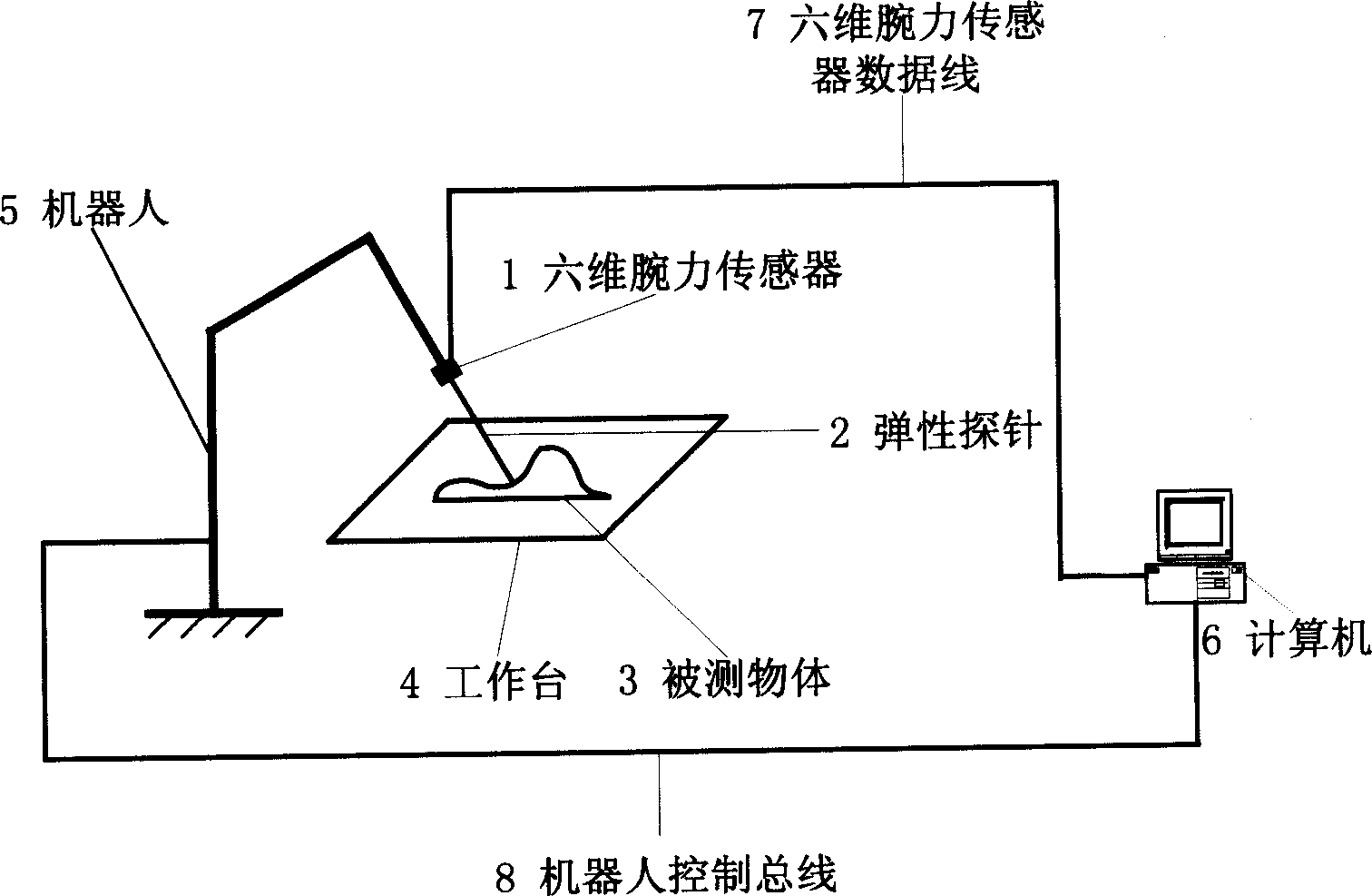

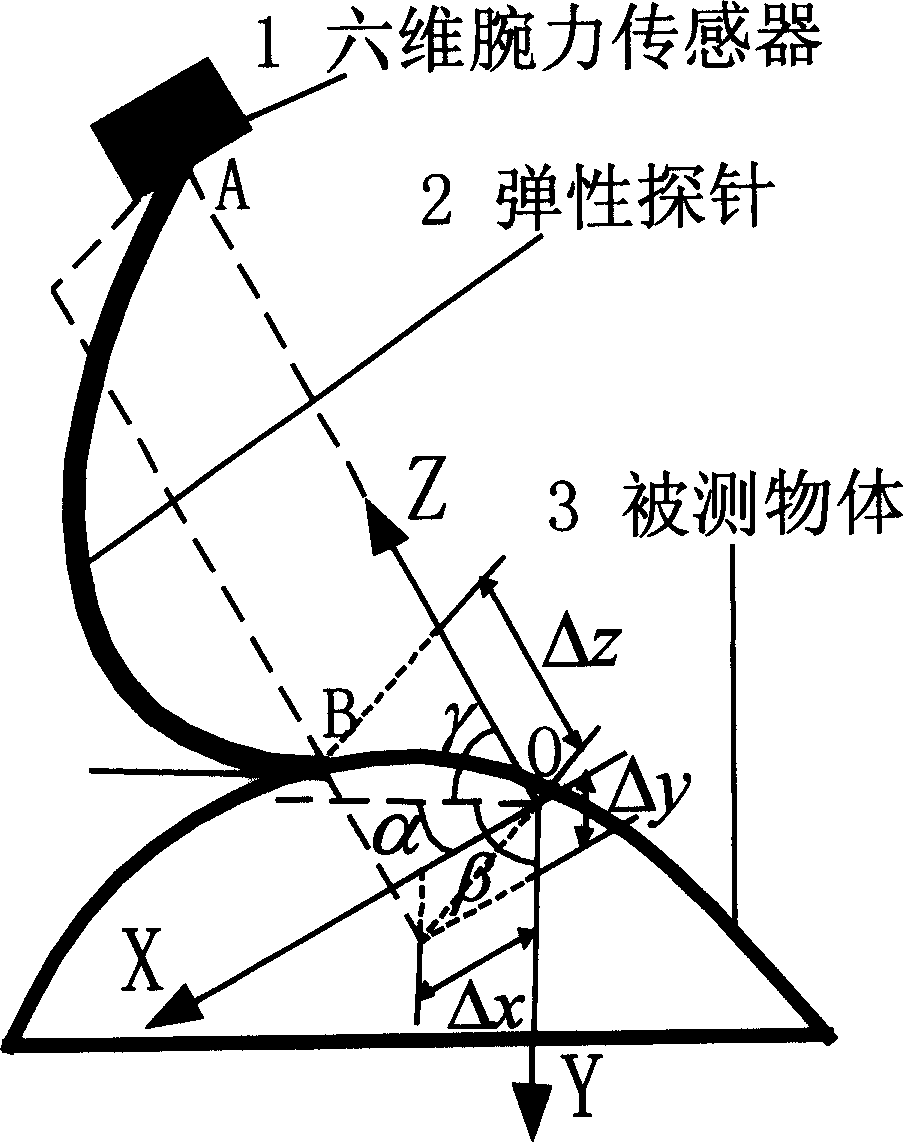

[0016] Such as figure 1 As shown, the six-dimensional wrist force sensor 1 and the elastic probe 2 are sequentially fixed on the wrist of the robot 5 and the end of the six-dimensional wrist force sensor 1 . The measured object 3 is placed on the workbench 4, and the six-dimensional wrist force sensor 1 collects the information of the contact force between the probe and the measured object 3, and transmits it to the computer 6 through the data line 7. Through the processing of the force information, the probe can be obtained. The force on the needle in the directions of x, y, and z axes, and the moment around the three axes. Such as figure 2 As shown, AO is the position where the probe does not deform, and AB is the position where the probe deforms during actual measurement. According to the physical characteristics of the probe, the elastic deformation Δx, Δy, Δz of the probe end along the three axes, and the angles α, β, γ between the tangent line of the probe end and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com